Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

The advantages of plasma spraying equipment plasma surface treatment PET plastic sprayin

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-01-24

- Views:

(Summary description)The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying: The PET plastic pre-spraying plasma surface treatment equipment mainly provides pre-treatment for bonding, coating, sputtering and other processes in the digital industry. PET plastic plasma spraying equipment is widely used in digital products for mobile phone casings, mobile phone buttons, notebook computer casings, notebook keyboards, plastic products, etc. Widely used raw materials for printing, coating and bonding of polyethylene, polypropylene, polyvinyl chloride, polyester, polyoxymethylene, PTFE, vinyl, nylon, (silicon) rubber, plexiglass, ABS and other plastics Surface pretreatment of other processes. The materials suitable for plasma spraying equipment plasma are polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), high impact polystyrene (HIPS), ABS, PC , EPDM, polyester (PET, APET), polyurethane (PUL), polyoxymethylene, polytetrafluoroethylene, vinyl, nylon, (silicon) rubber, glass, plexiglass and other polymer materials and glass, ceramics. After treatment, the surface adhesion of the material is usually 55~80 dynes/cm. The shape, width, height, material type, process type, and need for online processing of these materials all directly affect and determine the solution of the entire surface treatment equipment. Plasma, the plasma surface treatment equipment before PET plastic spraying, is also called plasma spraying equipment, plasma surface grinding machine, plasma processor, etc. The plasma surface treatment equipment before PET plastic spraying can clean, activate and coat the surface of various materials to achieve the effect of thorough cleaning or modification without damaging the surface of the object. The advantages of plasma spraying equipment surface treatment PET plastic spraying: The plasma action process is a gas-solid phase dry reaction, which does not consume water resources, does not need to add chemicals, and does not pollute the environment. Adjustable plasma power, processing distance, cleaning speed for quality control. Close to normal temperature, especially suitable for polymer materials, with longer storage time and higher surface tension than corona and flame methods. There is no limit to the geometry of the objects to be processed, large or small, simple or complex, parts or textiles.

The advantages of plasma spraying equipment plasma surface treatment PET plastic sprayin

(Summary description)The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying:

The PET plastic pre-spraying plasma surface treatment equipment mainly provides pre-treatment for bonding, coating, sputtering and other processes in the digital industry. PET plastic plasma spraying equipment is widely used in digital products for mobile phone casings, mobile phone buttons, notebook computer casings, notebook keyboards, plastic products, etc. Widely used raw materials for printing, coating and bonding of polyethylene, polypropylene, polyvinyl chloride, polyester, polyoxymethylene, PTFE, vinyl, nylon, (silicon) rubber, plexiglass, ABS and other plastics Surface pretreatment of other processes.

The materials suitable for plasma spraying equipment plasma are polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), high impact polystyrene (HIPS), ABS, PC , EPDM, polyester (PET, APET), polyurethane (PUL), polyoxymethylene, polytetrafluoroethylene, vinyl, nylon, (silicon) rubber, glass, plexiglass and other polymer materials and glass, ceramics. After treatment, the surface adhesion of the material is usually 55~80 dynes/cm. The shape, width, height, material type, process type, and need for online processing of these materials all directly affect and determine the solution of the entire surface treatment equipment.

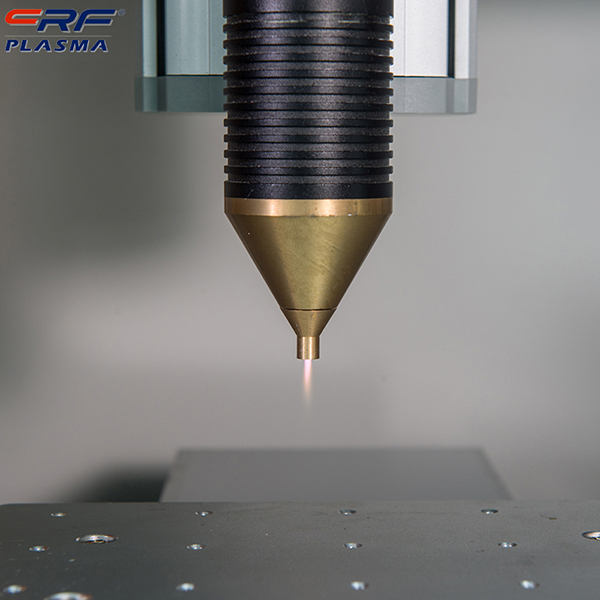

Plasma, the plasma surface treatment equipment before PET plastic spraying, is also called plasma spraying equipment, plasma surface grinding machine, plasma processor, etc. The plasma surface treatment equipment before PET plastic spraying can clean, activate and coat the surface of various materials to achieve the effect of thorough cleaning or modification without damaging the surface of the object.

The advantages of plasma spraying equipment surface treatment PET plastic spraying:

The plasma action process is a gas-solid phase dry reaction, which does not consume water resources, does not need to add chemicals, and does not pollute the environment. Adjustable plasma power, processing distance, cleaning speed for quality control. Close to normal temperature, especially suitable for polymer materials, with longer storage time and higher surface tension than corona and flame methods. There is no limit to the geometry of the objects to be processed, large or small, simple or complex, parts or textiles.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-01-24 14:50

- Views:

The advantages of plasma spraying equipment plasma surface treatment PET plastic spraying:

The PET plastic pre-spraying plasma surface treatment equipment mainly provides pre-treatment for bonding, coating, sputtering and other processes in the digital industry. PET plastic plasma spraying equipment is widely used in digital products for mobile phone casings, mobile phone buttons, notebook computer casings, notebook keyboards, plastic products, etc. Widely used raw materials for printing, coating and bonding of polyethylene, polypropylene, polyvinyl chloride, polyester, polyoxymethylene, PTFE, vinyl, nylon, (silicon) rubber, plexiglass, ABS and other plastics Surface pretreatment of other processes.

The materials suitable for plasma spraying equipment plasma are polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), high impact polystyrene (HIPS), ABS, PC , EPDM, polyester (PET, APET), polyurethane (PUL), polyoxymethylene, polytetrafluoroethylene, vinyl, nylon, (silicon) rubber, glass, plexiglass and other polymer materials and glass, ceramics. After treatment, the surface adhesion of the material is usually 55~80 dynes/cm. The shape, width, height, material type, process type, and need for online processing of these materials all directly affect and determine the solution of the entire surface treatment equipment.

The materials suitable for plasma spraying equipment plasma are polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), high impact polystyrene (HIPS), ABS, PC , EPDM, polyester (PET, APET), polyurethane (PUL), polyoxymethylene, polytetrafluoroethylene, vinyl, nylon, (silicon) rubber, glass, plexiglass and other polymer materials and glass, ceramics. After treatment, the surface adhesion of the material is usually 55~80 dynes/cm. The shape, width, height, material type, process type, and need for online processing of these materials all directly affect and determine the solution of the entire surface treatment equipment.

Plasma, the plasma surface treatment equipment before PET plastic spraying, is also called plasma spraying equipment, plasma surface grinding machine, plasma processor, etc. The plasma surface treatment equipment before PET plastic spraying can clean, activate and coat the surface of various materials to achieve the effect of thorough cleaning or modification without damaging the surface of the object.

The advantages of plasma spraying equipment surface treatment PET plastic spraying:

The plasma action process is a gas-solid phase dry reaction, which does not consume water resources, does not need to add chemicals, and does not pollute the environment. Adjustable plasma power, processing distance, cleaning speed for quality control. Close to normal temperature, especially suitable for polymer materials, with longer storage time and higher surface tension than corona and flame methods. There is no limit to the geometry of the objects to be processed, large or small, simple or complex, parts or textiles.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen