Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

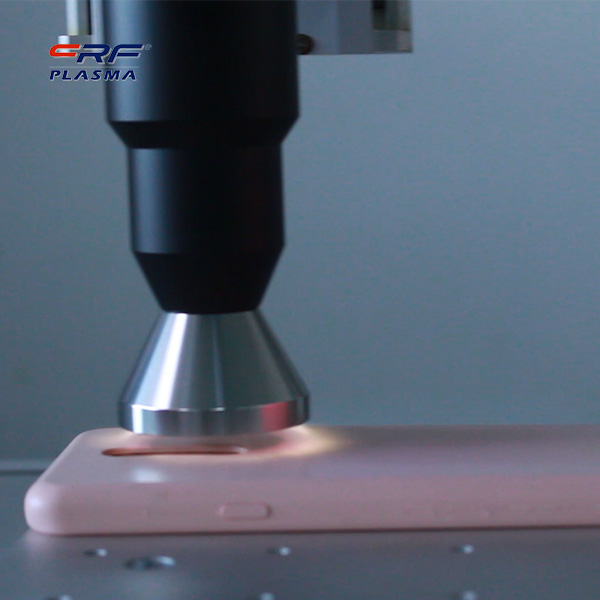

Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-01-16

- Views:

(Summary description)Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology: Wood-plastic composite material is a composite material made of thermoplastics and bamboo fibers with a small amount of chemical additives and fillers and other auxiliary agents, through a special composite method, and has the dual characteristics of plastic and bamboo, that is, it has the following Advantages: good acid and alkali resistance, chemical resistance, salt water resistance, can be used at low temperature, UV resistance, no rot, no cracking or warping and other mechanical properties, low price, long service life, easy to shape, easy to process , recyclable, no formaldehyde and other harmful gas release, etc., has been widely used in automobile manufacturing, construction, transportation, packaging and other fields. However, due to the poor wettability and poor adhesion of the surface of the bamboo-plastic composite material, the bonding process on the surface is greatly affected. In order to improve the wettability of the material surface, the ideal modification method is low temperature plasma treatment technology. Plasma is an ionized gas-like substance", containing electrons, positive ions and neutral particles, a high-energy aggregate of various particles. Plasma is divided into high-temperature plasma and low-temperature plasma according to temperature. Usually, low temperature plasma Plasma treatment techniques are used for the modification of material surfaces. The energy of the active particles in the plasma of low temperature plasma treatment technology is generally close to or exceeds the bond energy of C-C or other carbon bonds, which will modify the surface of the composite material and cause complex physical and chemical changes on the surface of the material, such as Etching, cross-linking, etc. to improve the contact angle and surface energy of the polymer surface. The increase of plasma discharge power of low temperature plasma treatment technology increases the number of active particles in the plasma atmosphere, the energy increases, the etching effect of active particles on the surface of the sample is strengthened, the contact angle of the surface of the sample decreases, and the surface of the sample decreases. Wetting is improved. With the increase of the discharge power, the contact angle of the sample surface increases with the increase of the discharge power. As the treatment time increases, the thickness of the oxide layer increases and the polarity of the oxygen-containing functional groups increases. After low-temperature plasma treatment of the sample, the water absorption rate of the sample increases with the increase of the low-temperature plasma discharge power; after the low-temperature plasma treatment of the sample, the water absorption rate of the sample decreases with the increase of the low-temperature plasma discharge power . This is because after the low-temperature plasma treatment technology plasma treats the sample, increasing the low-temperature plasma discharge power will promote the conversion of inactive particles inside the low-temperature plasma into active particles with higher energy that are easy to participate in the reaction, which is beneficial to the low-temperature plasma. The reaction between the body and the surface of the sample increases the oxygen content on the surface of the sample, the number of polar oxygen-containing functional groups increases, and the water absorption rate increases. With the further increase of the power, the energy obtained by the active particles from the electric field increases, and the probability of the particles colliding with each other increases, resulting in the loss of particle energy and the weakening of the molecular interaction between the active particles and the sample surface, resulting in wetting. The relative decline of the property, the water absorption rate decreased. This is because with the increase of treatment time, the number of polar oxygen-containing functional groups introduced on the surface of the sample increases, and the surface polarity increases. Low-temperature plasma treatment technology After plasma treatment, the amount of -COC on the surface of the sample increases, but with the increase of low-temperature plasma treatment time, the amount of -COC on the surface gradually decreases. The oxide layer thickens, and the attractive -COC on the surface of the sample is further oxidized to -C=O.

Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology

(Summary description)Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology:

Wood-plastic composite material is a composite material made of thermoplastics and bamboo fibers with a small amount of chemical additives and fillers and other auxiliary agents, through a special composite method, and has the dual characteristics of plastic and bamboo, that is, it has the following Advantages: good acid and alkali resistance, chemical resistance, salt water resistance, can be used at low temperature, UV resistance, no rot, no cracking or warping and other mechanical properties, low price, long service life, easy to shape, easy to process , recyclable, no formaldehyde and other harmful gas release, etc., has been widely used in automobile manufacturing, construction, transportation, packaging and other fields.

However, due to the poor wettability and poor adhesion of the surface of the bamboo-plastic composite material, the bonding process on the surface is greatly affected. In order to improve the wettability of the material surface, the ideal modification method is low temperature plasma treatment technology. Plasma is an ionized gas-like substance", containing electrons, positive ions and neutral particles, a high-energy aggregate of various particles. Plasma is divided into high-temperature plasma and low-temperature plasma according to temperature. Usually, low temperature plasma Plasma treatment techniques are used for the modification of material surfaces.

The energy of the active particles in the plasma of low temperature plasma treatment technology is generally close to or exceeds the bond energy of C-C or other carbon bonds, which will modify the surface of the composite material and cause complex physical and chemical changes on the surface of the material, such as Etching, cross-linking, etc. to improve the contact angle and surface energy of the polymer surface. The increase of plasma discharge power of low temperature plasma treatment technology increases the number of active particles in the plasma atmosphere, the energy increases, the etching effect of active particles on the surface of the sample is strengthened, the contact angle of the surface of the sample decreases, and the surface of the sample decreases. Wetting is improved.

With the increase of the discharge power, the contact angle of the sample surface increases with the increase of the discharge power. As the treatment time increases, the thickness of the oxide layer increases and the polarity of the oxygen-containing functional groups increases. After low-temperature plasma treatment of the sample, the water absorption rate of the sample increases with the increase of the low-temperature plasma discharge power; after the low-temperature plasma treatment of the sample, the water absorption rate of the sample decreases with the increase of the low-temperature plasma discharge power . This is because after the low-temperature plasma treatment technology plasma treats the sample, increasing the low-temperature plasma discharge power will promote the conversion of inactive particles inside the low-temperature plasma into active particles with higher energy that are easy to participate in the reaction, which is beneficial to the low-temperature plasma. The reaction between the body and the surface of the sample increases the oxygen content on the surface of the sample, the number of polar oxygen-containing functional groups increases, and the water absorption rate increases.

With the further increase of the power, the energy obtained by the active particles from the electric field increases, and the probability of the particles colliding with each other increases, resulting in the loss of particle energy and the weakening of the molecular interaction between the active particles and the sample surface, resulting in wetting. The relative decline of the property, the water absorption rate decreased. This is because with the increase of treatment time, the number of polar oxygen-containing functional groups introduced on the surface of the sample increases, and the surface polarity increases. Low-temperature plasma treatment technology After plasma treatment, the amount of -COC on the surface of the sample increases, but with the increase of low-temperature plasma treatment time, the amount of -COC on the surface gradually decreases. The oxide layer thickens, and the attractive -COC on the surface of the sample is further oxidized to -C=O.

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-01-16 19:58

- Views:

Surface modification of bamboo powder/PETG composites by low temperature plasma treatment technology:

Wood-plastic composite material is a composite material made of thermoplastics and bamboo fibers with a small amount of chemical additives and fillers and other auxiliary agents, through a special composite method, and has the dual characteristics of plastic and bamboo, that is, it has the following Advantages: good acid and alkali resistance, chemical resistance, salt water resistance, can be used at low temperature, UV resistance, no rot, no cracking or warping and other mechanical properties, low price, long service life, easy to shape, easy to process , recyclable, no formaldehyde and other harmful gas release, etc., has been widely used in automobile manufacturing, construction, transportation, packaging and other fields.

However, due to the poor wettability and poor adhesion of the surface of the bamboo-plastic composite material, the bonding process on the surface is greatly affected. In order to improve the wettability of the material surface, the ideal modification method is low temperature plasma treatment technology. Plasma is an ionized gas-like substance", containing electrons, positive ions and neutral particles, a high-energy aggregate of various particles. Plasma is divided into high-temperature plasma and low-temperature plasma according to temperature. Usually, low temperature plasma Plasma treatment techniques are used for the modification of material surfaces.

The energy of the active particles in the plasma of low temperature plasma treatment technology is generally close to or exceeds the bond energy of C-C or other carbon bonds, which will modify the surface of the composite material and cause complex physical and chemical changes on the surface of the material, such as Etching, cross-linking, etc. to improve the contact angle and surface energy of the polymer surface. The increase of plasma discharge power of low temperature plasma treatment technology increases the number of active particles in the plasma atmosphere, the energy increases, the etching effect of active particles on the surface of the sample is strengthened, the contact angle of the surface of the sample decreases, and the surface of the sample decreases. Wetting is improved.

The energy of the active particles in the plasma of low temperature plasma treatment technology is generally close to or exceeds the bond energy of C-C or other carbon bonds, which will modify the surface of the composite material and cause complex physical and chemical changes on the surface of the material, such as Etching, cross-linking, etc. to improve the contact angle and surface energy of the polymer surface. The increase of plasma discharge power of low temperature plasma treatment technology increases the number of active particles in the plasma atmosphere, the energy increases, the etching effect of active particles on the surface of the sample is strengthened, the contact angle of the surface of the sample decreases, and the surface of the sample decreases. Wetting is improved.

With the increase of the discharge power, the contact angle of the sample surface increases with the increase of the discharge power. As the treatment time increases, the thickness of the oxide layer increases and the polarity of the oxygen-containing functional groups increases. After low-temperature plasma treatment of the sample, the water absorption rate of the sample increases with the increase of the low-temperature plasma discharge power; after the low-temperature plasma treatment of the sample, the water absorption rate of the sample decreases with the increase of the low-temperature plasma discharge power . This is because after the low-temperature plasma treatment technology plasma treats the sample, increasing the low-temperature plasma discharge power will promote the conversion of inactive particles inside the low-temperature plasma into active particles with higher energy that are easy to participate in the reaction, which is beneficial to the low-temperature plasma. The reaction between the body and the surface of the sample increases the oxygen content on the surface of the sample, the number of polar oxygen-containing functional groups increases, and the water absorption rate increases.

With the further increase of the power, the energy obtained by the active particles from the electric field increases, and the probability of the particles colliding with each other increases, resulting in the loss of particle energy and the weakening of the molecular interaction between the active particles and the sample surface, resulting in wetting. The relative decline of the property, the water absorption rate decreased. This is because with the increase of treatment time, the number of polar oxygen-containing functional groups introduced on the surface of the sample increases, and the surface polarity increases. Low-temperature plasma treatment technology After plasma treatment, the amount of -COC on the surface of the sample increases, but with the increase of low-temperature plasma treatment time, the amount of -COC on the surface gradually decreases. The oxide layer thickens, and the attractive -COC on the surface of the sample is further oxidized to -C=O.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen