Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

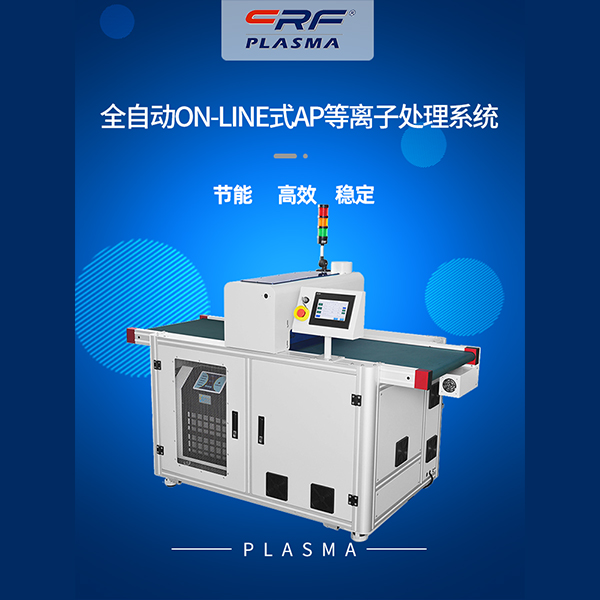

Glass plasma spraying plasma cleaning machine surface activation cleaning treatment

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-01-13

- Views:

(Summary description)Glass plasma spraying plasma cleaning machine surface activation cleaning treatment: Nowadays, when people buy perfume, they not only pay attention to the fragrance, but also pay attention to the packaging. The packaging is as important as the fragrance. At present, plasma cleaning machine technology is used before printing on perfume bottles of big brands. Traditionally, there are only three basic colors for glass production: white, green or brown. In order to produce more delicate glass packaging, many products, such as cosmetic packaging, go through a dyeing process, and metal beverage containers also need to be painted to attract end consumers. Advantages of cleaning and activation treatment before glass plasma spraying: Can be easily integrated into glass plasma spraying production line; reduce reject rate; use innovative glass spraying technology for plasma treatment; fine plasma cleaning machine to improve glass surface microstructure; plasma cleaning activation treatment before glass spraying. The advantages of plasma cleaning machine surface activation cleaning compared to traditional cleaning methods: It can handle samples of various shapes: for samples with complex shapes, plasma cleaning can find the right solution. No additional auxiliary items and conditions are required for the treatment process: the atmospheric plasma cleaner only needs 220 volts AC and CDA compressed air and no additional items and conditions are required. Low operating cost: fully automatic operation, 24-hour continuous operation, no need for manual supervision, operating power can be as low as 600W. Stable treatment effect: The treatment effect of plasma cleaning is very uniform and stable, and it maintains a good effect for a long time after conventional sample treatment. There is no pollution in the whole processing process: the plasma cleaning machine itself is a very environmentally friendly equipment, which does not produce any pollution, nor does it produce any pollution during the processing. The plasma cleaning machine has high processing efficiency and can realize fully automatic online production: as long as the surface of the sample is treated in a short time, the plasma cleaning in the atmosphere can achieve the effect within 2 seconds. It can be matched with the original production line to realize fully automatic online production and save labor costs. Low processing temperature: The processing temperature can be as low as 80 °C and below 50 °C, and the low processing temperature can ensure that there is no thermal shock to the surface of the sample.

Glass plasma spraying plasma cleaning machine surface activation cleaning treatment

(Summary description)Glass plasma spraying plasma cleaning machine surface activation cleaning treatment:

Nowadays, when people buy perfume, they not only pay attention to the fragrance, but also pay attention to the packaging. The packaging is as important as the fragrance. At present, plasma cleaning machine technology is used before printing on perfume bottles of big brands. Traditionally, there are only three basic colors for glass production: white, green or brown. In order to produce more delicate glass packaging, many products, such as cosmetic packaging, go through a dyeing process, and metal beverage containers also need to be painted to attract end consumers.

Advantages of cleaning and activation treatment before glass plasma spraying:

Can be easily integrated into glass plasma spraying production line; reduce reject rate; use innovative glass spraying technology for plasma treatment; fine plasma cleaning machine to improve glass surface microstructure; plasma cleaning activation treatment before glass spraying.

The advantages of plasma cleaning machine surface activation cleaning compared to traditional cleaning methods:

It can handle samples of various shapes: for samples with complex shapes, plasma cleaning can find the right solution. No additional auxiliary items and conditions are required for the treatment process: the atmospheric plasma cleaner only needs 220 volts AC and CDA compressed air and no additional items and conditions are required. Low operating cost: fully automatic operation, 24-hour continuous operation, no need for manual supervision, operating power can be as low as 600W. Stable treatment effect: The treatment effect of plasma cleaning is very uniform and stable, and it maintains a good effect for a long time after conventional sample treatment.

There is no pollution in the whole processing process: the plasma cleaning machine itself is a very environmentally friendly equipment, which does not produce any pollution, nor does it produce any pollution during the processing. The plasma cleaning machine has high processing efficiency and can realize fully automatic online production: as long as the surface of the sample is treated in a short time, the plasma cleaning in the atmosphere can achieve the effect within 2 seconds. It can be matched with the original production line to realize fully automatic online production and save labor costs. Low processing temperature: The processing temperature can be as low as 80 °C and below 50 °C, and the low processing temperature can ensure that there is no thermal shock to the surface of the sample.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-01-13 18:09

- Views:

Glass plasma spraying plasma cleaning machine surface activation cleaning treatment:

Nowadays, when people buy perfume, they not only pay attention to the fragrance, but also pay attention to the packaging. The packaging is as important as the fragrance. At present, plasma cleaning machine technology is used before printing on perfume bottles of big brands. Traditionally, there are only three basic colors for glass production: white, green or brown. In order to produce more delicate glass packaging, many products, such as cosmetic packaging, go through a dyeing process, and metal beverage containers also need to be painted to attract end consumers.

Advantages of cleaning and activation treatment before glass plasma spraying:

Advantages of cleaning and activation treatment before glass plasma spraying:

Can be easily integrated into glass plasma spraying production line; reduce reject rate; use innovative glass spraying technology for plasma treatment; fine plasma cleaning machine to improve glass surface microstructure; plasma cleaning activation treatment before glass spraying.

The advantages of plasma cleaning machine surface activation cleaning compared to traditional cleaning methods:

It can handle samples of various shapes: for samples with complex shapes, plasma cleaning can find the right solution. No additional auxiliary items and conditions are required for the treatment process: the atmospheric plasma cleaner only needs 220 volts AC and CDA compressed air and no additional items and conditions are required. Low operating cost: fully automatic operation, 24-hour continuous operation, no need for manual supervision, operating power can be as low as 600W. Stable treatment effect: The treatment effect of plasma cleaning is very uniform and stable, and it maintains a good effect for a long time after conventional sample treatment.

There is no pollution in the whole processing process: the plasma cleaning machine itself is a very environmentally friendly equipment, which does not produce any pollution, nor does it produce any pollution during the processing. The plasma cleaning machine has high processing efficiency and can realize fully automatic online production: as long as the surface of the sample is treated in a short time, the plasma cleaning in the atmosphere can achieve the effect within 2 seconds. It can be matched with the original production line to realize fully automatic online production and save labor costs. Low processing temperature: The processing temperature can be as low as 80 °C and below 50 °C, and the low processing temperature can ensure that there is no thermal shock to the surface of the sample.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen