Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

What are the unexpected effects of using wide-format plasma equipment? Let's take a look at it together

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-12-01

- Views:

(Summary description)What are the unexpected effects of using wide-format plasma equipment? Let's take a look at it together: The wide-width plasma equipment adopts digital control technology, which has a high degree of automation; the control equipment has high precision and good control of time; the correct cleaning method will not cause damage to the machine and can extend the service life of the machine; and it is in the atmospheric environment Cleaning will not cause secondary pollution to the environment, so what are the advantages of using a wide-format plasma equipment for plasma cleaning? The wide-format plasma equipment will be dried after cleaning, and then the next process can be carried out, which can effectively improve the processing efficiency. Application effect of wide-format plasma equipment: 1. Improve the surface adhesion ability and improve the reliability and durability of surface adhesion. 2. After the atmospheric pressure plasma treatment is used, the surface energy of materials such as various polymer plastics, ceramics, glass or metals have been improved. 3. Through such a treatment process, the surface tension performance of the product is improved, and it is more suitable for processing requirements such as coating and bonding in the industry. 4. The processing surface can be customized according to the customer, and a large area can be processed at one time, making the processing easier. The wide-format plasma equipment technology has the following characteristics: 1. The wide-width plasma equipment can process materials with a width of 1-3 meters, which can meet the surface treatment requirements of most existing industrial materials. 2. High uniformity: The atmospheric pressure plasma is a glow-type plasma screen, which directly acts on the surface of the material. Experiments have shown that the same material can be processed at different positions with high uniformity. This feature is important for the continuous casting, Processes such as coating and printing are of great significance. 3. Low cost: The gas pressure plasma equipment has low energy consumption, and the operating cost is mainly gas. Take the consumption gas argon as an example, its consumption is less than 1/20 of the consumption of corona plasma gas. 4. Safe and convenient to use: Atmospheric plasma, also known as low temperature plasma, does not damage the surface of the material. No vacuum chamber, no arc, no harmful gas suction system, long-term use will not cause harm to the operator's body. 5. The effect is controlled: There are three effect modes for the large-width plasma equipment plasma to choose from. First, the choice of argon/oxygen combination is mainly for non-metallic materials, and has higher requirements for treatment effects. Secondly, choose the combination of argon/nitrogen, mainly for areas where there are unprocessable metals in the product to be processed. In this solution, due to the strong oxidation of oxygen, the problem can be controlled after replacing nitrogen. Thirdly, using only argon gas, the surface modification can also be achieved using only argon gas, but the effect is relatively low. This situation is rather special, and it is a scheme adopted by some industrial users when they need to perform uniform surface modification at the same time.

What are the unexpected effects of using wide-format plasma equipment? Let's take a look at it together

(Summary description)What are the unexpected effects of using wide-format plasma equipment? Let's take a look at it together:

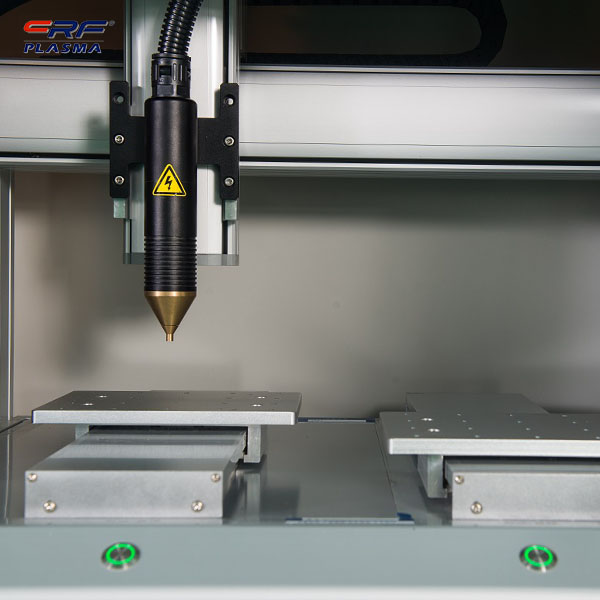

The wide-width plasma equipment adopts digital control technology, which has a high degree of automation; the control equipment has high precision and good control of time; the correct cleaning method will not cause damage to the machine and can extend the service life of the machine; and it is in the atmospheric environment Cleaning will not cause secondary pollution to the environment, so what are the advantages of using a wide-format plasma equipment for plasma cleaning? The wide-format plasma equipment will be dried after cleaning, and then the next process can be carried out, which can effectively improve the processing efficiency.

Application effect of wide-format plasma equipment:

1. Improve the surface adhesion ability and improve the reliability and durability of surface adhesion.

2. After the atmospheric pressure plasma treatment is used, the surface energy of materials such as various polymer plastics, ceramics, glass or metals have been improved.

3. Through such a treatment process, the surface tension performance of the product is improved, and it is more suitable for processing requirements such as coating and bonding in the industry.

4. The processing surface can be customized according to the customer, and a large area can be processed at one time, making the processing easier.

The wide-format plasma equipment technology has the following characteristics:

1. The wide-width plasma equipment can process materials with a width of 1-3 meters, which can meet the surface treatment requirements of most existing industrial materials.

2. High uniformity: The atmospheric pressure plasma is a glow-type plasma screen, which directly acts on the surface of the material. Experiments have shown that the same material can be processed at different positions with high uniformity. This feature is important for the continuous casting, Processes such as coating and printing are of great significance.

3. Low cost: The gas pressure plasma equipment has low energy consumption, and the operating cost is mainly gas. Take the consumption gas argon as an example, its consumption is less than 1/20 of the consumption of corona plasma gas.

4. Safe and convenient to use: Atmospheric plasma, also known as low temperature plasma, does not damage the surface of the material. No vacuum chamber, no arc, no harmful gas suction system, long-term use will not cause harm to the operator's body.

5. The effect is controlled: There are three effect modes for the large-width plasma equipment plasma to choose from. First, the choice of argon/oxygen combination is mainly for non-metallic materials, and has higher requirements for treatment effects. Secondly, choose the combination of argon/nitrogen, mainly for areas where there are unprocessable metals in the product to be processed. In this solution, due to the strong oxidation of oxygen, the problem can be controlled after replacing nitrogen. Thirdly, using only argon gas, the surface modification can also be achieved using only argon gas, but the effect is relatively low. This situation is rather special, and it is a scheme adopted by some industrial users when they need to perform uniform surface modification at the same time.

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-12-01 18:17

- Views:

What are the unexpected effects of using wide-format plasma equipment? Let's take a look at it together:

The wide-width plasma equipment adopts digital control technology, which has a high degree of automation; the control equipment has high precision and good control of time; the correct cleaning method will not cause damage to the machine and can extend the service life of the machine; and it is in the atmospheric environment Cleaning will not cause secondary pollution to the environment, so what are the advantages of using a wide-format plasma equipment for plasma cleaning? The wide-format plasma equipment will be dried after cleaning, and then the next process can be carried out, which can effectively improve the processing efficiency.

Application effect of wide-format plasma equipment:

1. Improve the surface adhesion ability and improve the reliability and durability of surface adhesion.

1. Improve the surface adhesion ability and improve the reliability and durability of surface adhesion.

2. After the atmospheric pressure plasma treatment is used, the surface energy of materials such as various polymer plastics, ceramics, glass or metals have been improved.

3. Through such a treatment process, the surface tension performance of the product is improved, and it is more suitable for processing requirements such as coating and bonding in the industry.

4. The processing surface can be customized according to the customer, and a large area can be processed at one time, making the processing easier.

The wide-format plasma equipment technology has the following characteristics:

1. The wide-width plasma equipment can process materials with a width of 1-3 meters, which can meet the surface treatment requirements of most existing industrial materials.

2. High uniformity: The atmospheric pressure plasma is a glow-type plasma screen, which directly acts on the surface of the material. Experiments have shown that the same material can be processed at different positions with high uniformity. This feature is important for the continuous casting, Processes such as coating and printing are of great significance.

3. Low cost: The gas pressure plasma equipment has low energy consumption, and the operating cost is mainly gas. Take the consumption gas argon as an example, its consumption is less than 1/20 of the consumption of corona plasma gas.

4. Safe and convenient to use: Atmospheric plasma, also known as low temperature plasma, does not damage the surface of the material. No vacuum chamber, no arc, no harmful gas suction system, long-term use will not cause harm to the operator's body.

5. The effect is controlled: There are three effect modes for the large-width plasma equipment plasma to choose from. First, the choice of argon/oxygen combination is mainly for non-metallic materials, and has higher requirements for treatment effects. Secondly, choose the combination of argon/nitrogen, mainly for areas where there are unprocessable metals in the product to be processed. In this solution, due to the strong oxidation of oxygen, the problem can be controlled after replacing nitrogen. Thirdly, using only argon gas, the surface modification can also be achieved using only argon gas, but the effect is relatively low. This situation is rather special, and it is a scheme adopted by some industrial users when they need to perform uniform surface modification at the same time.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen