Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Plasma treatment machine to clean the surface can improve the surface tension, bonding modification applications

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-19

- Views:

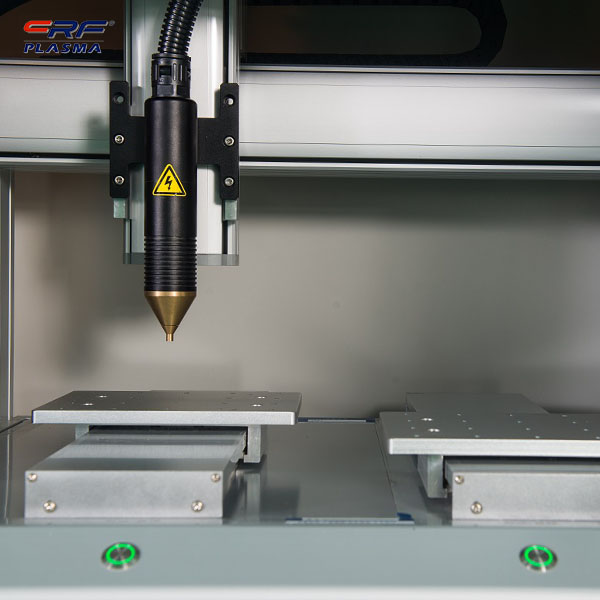

(Summary description)Plasma treatment machine to clean the surface can improve the surface tension, bonding modification applications: Plasma treatment machine can improve surface tension, fine cleaning, eliminate static electricity, activate surface and other functions. It is widely used in surface modification treatment of glass, metal, cable, rubber, plastic, paste box, and rubber. The plasma treatment machine cleans the surface, so that the release agent and auxiliary agent can be on the surface, and the activation process can ensure the quality of the subsequent bonding process and coating process, and the coating treatment can further improve the composite Surface characteristics. Using this plasma technology, materials can be efficiently surface pretreated according to special process requirements. The advantages of plasma treatment machine are simple process, convenient operation, fast processing speed, good treatment effect, low environmental pollution and energy saving; use plasma treatment machine technology to modify plastic components to improve the wetting rate of plastics; use plasma technology Reflective treatment for plastic window glass, car blinds, lamps, halogen sky lights, etc.; polyester fiber is strong and durable, but compact in structure, poor in water absorption, and not easy to dye. Low temperature nitrogen plasma is used to initiate acrylamide to graft polyester fabric Modification can significantly improve the dye uptake, dyeing depth and hydrophilicity of polyester fabrics after grafting. The polypropylene film is treated with polypropylene plasma, amino groups are introduced, and the sugar oxidase immobilized by covalent bond grafting, the grafting rates are 52μg/cm2 and 34μg/cm2 respectively; plasma treatment machine plasma is performed on the surface of medical materials During the treatment, groups such as amino groups and carbonyl groups can be introduced, and the grafting reaction of the biologically active substances with these groups can be fixed on the surface of the material.

Plasma treatment machine to clean the surface can improve the surface tension, bonding modification applications

(Summary description)Plasma treatment machine to clean the surface can improve the surface tension, bonding modification applications:

Plasma treatment machine can improve surface tension, fine cleaning, eliminate static electricity, activate surface and other functions. It is widely used in surface modification treatment of glass, metal, cable, rubber, plastic, paste box, and rubber.

The plasma treatment machine cleans the surface, so that the release agent and auxiliary agent can be on the surface, and the activation process can ensure the quality of the subsequent bonding process and coating process, and the coating treatment can further improve the composite Surface characteristics. Using this plasma technology, materials can be efficiently surface pretreated according to special process requirements.

The advantages of plasma treatment machine are simple process, convenient operation, fast processing speed, good treatment effect, low environmental pollution and energy saving; use plasma treatment machine technology to modify plastic components to improve the wetting rate of plastics; use plasma technology Reflective treatment for plastic window glass, car blinds, lamps, halogen sky lights, etc.; polyester fiber is strong and durable, but compact in structure, poor in water absorption, and not easy to dye. Low temperature nitrogen plasma is used to initiate acrylamide to graft polyester fabric Modification can significantly improve the dye uptake, dyeing depth and hydrophilicity of polyester fabrics after grafting.

The polypropylene film is treated with polypropylene plasma, amino groups are introduced, and the sugar oxidase immobilized by covalent bond grafting, the grafting rates are 52μg/cm2 and 34μg/cm2 respectively; plasma treatment machine plasma is performed on the surface of medical materials During the treatment, groups such as amino groups and carbonyl groups can be introduced, and the grafting reaction of the biologically active substances with these groups can be fixed on the surface of the material.

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-19 18:09

- Views:

Plasma treatment machine to clean the surface can improve the surface tension, bonding modification applications:

Plasma treatment machine can improve surface tension, fine cleaning, eliminate static electricity, activate surface and other functions. It is widely used in surface modification treatment of glass, metal, cable, rubber, plastic, paste box, and rubber.

The plasma treatment machine cleans the surface, so that the release agent and auxiliary agent can be on the surface, and the activation process can ensure the quality of the subsequent bonding process and coating process, and the coating treatment can further improve the composite Surface characteristics. Using this plasma technology, materials can be efficiently surface pretreated according to special process requirements.

The advantages of plasma treatment machine are simple process, convenient operation, fast processing speed, good treatment effect, low environmental pollution and energy saving; use plasma treatment machine technology to modify plastic components to improve the wetting rate of plastics; use plasma technology Reflective treatment for plastic window glass, car blinds, lamps, halogen sky lights, etc.; polyester fiber is strong and durable, but compact in structure, poor in water absorption, and not easy to dye. Low temperature nitrogen plasma is used to initiate acrylamide to graft polyester fabric Modification can significantly improve the dye uptake, dyeing depth and hydrophilicity of polyester fabrics after grafting.

The advantages of plasma treatment machine are simple process, convenient operation, fast processing speed, good treatment effect, low environmental pollution and energy saving; use plasma treatment machine technology to modify plastic components to improve the wetting rate of plastics; use plasma technology Reflective treatment for plastic window glass, car blinds, lamps, halogen sky lights, etc.; polyester fiber is strong and durable, but compact in structure, poor in water absorption, and not easy to dye. Low temperature nitrogen plasma is used to initiate acrylamide to graft polyester fabric Modification can significantly improve the dye uptake, dyeing depth and hydrophilicity of polyester fabrics after grafting.

The polypropylene film is treated with polypropylene plasma, amino groups are introduced, and the sugar oxidase immobilized by covalent bond grafting, the grafting rates are 52μg/cm2 and 34μg/cm2 respectively; plasma treatment machine plasma is performed on the surface of medical materials During the treatment, groups such as amino groups and carbonyl groups can be introduced, and the grafting reaction of the biologically active substances with these groups can be fixed on the surface of the material.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen