Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

What are the advantages of plasma cleaning technology What materials can be processed

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-22

- Views:

(Summary description)What are the advantages of plasma cleaning technology What materials can be processed: There are three forms of matter existing around us: solid, liquid and gaseous. Plasma is usually called the fourth state of matter. Ordinary gas is composed of electrically neutral molecules or atoms. Ionized gas is a collection of electrons, ions, atoms, molecules or free radical particles. The total number of positive and negative charges is always equal in value. Based on this plasma composition, ionized gas exhibits the following two properties: 1. Ionized gas is a conductive fluid that can maintain electrical neutrality on a macro scale comparable to the volume of gas. 2. There is a Coulomb force between the charged particles of the ionized gas, which causes the various overall motion behaviors of the charged particle swarm to be affected and dominated by the magnetic field. There are many ways to generate plasma. Natural methods exist between celestial bodies in the universe and the upper atmosphere. Artificial methods-generally discharge methods, radiation methods, vacuum ultraviolet light, lasers, combustion, shock waves, field ionization, etc. Discharge methods include DC discharge, low-frequency discharge, high-frequency discharge, microwave, and induction methods. We use 13.56MHz high-frequency power supply to generate glow discharge in the equipment, and realize various reaction mechanisms in different reaction chamber conditions, thereby producing different process effects. The important advantage of plasma cleaning technology lies in its versatility. It can be used for surface activation, cleaning, etching and deposition of a variety of materials. Why use plasma cleaning technology? This process directly applies a high-energy plasma stream to the surface to be cleaned to achieve the purpose of plasma cleaning. Choosing different gas types and ratios can meet many plasma cleaning requirements. For example, oxygen plasma can be used to oxidize organic deposits; inert argon plasma can be used to mechanically wash away particle contamination; hydrogen plasma can eliminate metal surface oxidation and so on. The application of plasma cleaning technology to clean organic matter on the surfaces of metals, ceramics and plastics greatly enhances the adhesion and bonding force on the surfaces of these materials. With the deepening of the research on this technology, its application has become more and more extensive. In the electronics field, this technology can be used for cleaning and etching of hybrid circuits, PCB boards, SMT, BGA, lead frames and flat panel displays; in the medical field, this technology should also be used to improve various catheters, ultra-fine catheters, and filters. Key indicators such as smoothness and wettability of medical devices such as sensors. In the large-scale integrated circuit and discrete device industries, plasma cleaning technology is generally used in the following key steps: 1. De-glue, treat the silicon wafer with oxygen plasma to remove the photoresist; 2. Plasma cleaning of the device substrate before metallization; 3. Plasma cleaning before bonding the hybrid circuit; 4. Plasma cleaning before bonding; 5. Plasma cleaning before capping the metalized ceramic tube; 6. The controllability and repeatability of the plasma cleaning technology process is reflected in the advantages of economy, environmental protection, high efficiency, high reliability and easy operation in the use of equipment.

What are the advantages of plasma cleaning technology What materials can be processed

(Summary description)What are the advantages of plasma cleaning technology What materials can be processed:

There are three forms of matter existing around us: solid, liquid and gaseous. Plasma is usually called the fourth state of matter. Ordinary gas is composed of electrically neutral molecules or atoms. Ionized gas is a collection of electrons, ions, atoms, molecules or free radical particles. The total number of positive and negative charges is always equal in value.

Based on this plasma composition, ionized gas exhibits the following two properties:

1. Ionized gas is a conductive fluid that can maintain electrical neutrality on a macro scale comparable to the volume of gas.

2. There is a Coulomb force between the charged particles of the ionized gas, which causes the various overall motion behaviors of the charged particle swarm to be affected and dominated by the magnetic field.

There are many ways to generate plasma. Natural methods exist between celestial bodies in the universe and the upper atmosphere. Artificial methods-generally discharge methods, radiation methods, vacuum ultraviolet light, lasers, combustion, shock waves, field ionization, etc.

Discharge methods include DC discharge, low-frequency discharge, high-frequency discharge, microwave, and induction methods. We use 13.56MHz high-frequency power supply to generate glow discharge in the equipment, and realize various reaction mechanisms in different reaction chamber conditions, thereby producing different process effects.

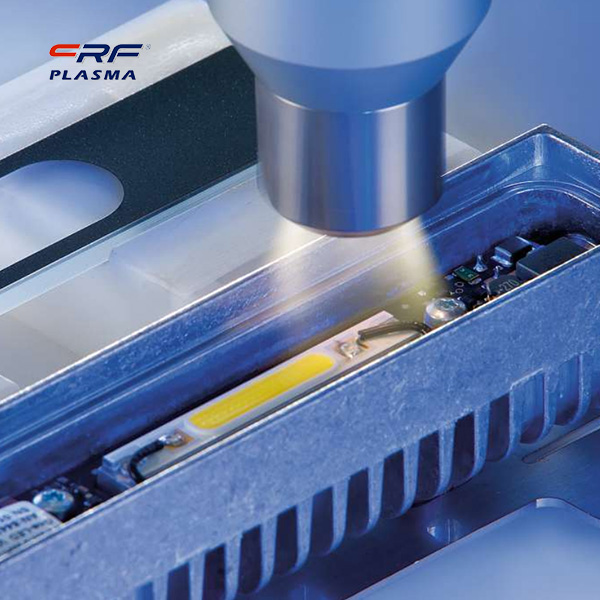

The important advantage of plasma cleaning technology lies in its versatility. It can be used for surface activation, cleaning, etching and deposition of a variety of materials.

Why use plasma cleaning technology? This process directly applies a high-energy plasma stream to the surface to be cleaned to achieve the purpose of plasma cleaning. Choosing different gas types and ratios can meet many plasma cleaning requirements.

For example, oxygen plasma can be used to oxidize organic deposits; inert argon plasma can be used to mechanically wash away particle contamination; hydrogen plasma can eliminate metal surface oxidation and so on.

The application of plasma cleaning technology to clean organic matter on the surfaces of metals, ceramics and plastics greatly enhances the adhesion and bonding force on the surfaces of these materials.

With the deepening of the research on this technology, its application has become more and more extensive. In the electronics field, this technology can be used for cleaning and etching of hybrid circuits, PCB boards, SMT, BGA, lead frames and flat panel displays; in the medical field, this technology should also be used to improve various catheters, ultra-fine catheters, and filters. Key indicators such as smoothness and wettability of medical devices such as sensors.

In the large-scale integrated circuit and discrete device industries, plasma cleaning technology is generally used in the following key steps:

1. De-glue, treat the silicon wafer with oxygen plasma to remove the photoresist;

2. Plasma cleaning of the device substrate before metallization;

3. Plasma cleaning before bonding the hybrid circuit;

4. Plasma cleaning before bonding;

5. Plasma cleaning before capping the metalized ceramic tube;

6. The controllability and repeatability of the plasma cleaning technology process is reflected in the advantages of economy, environmental protection, high efficiency, high reliability and easy operation in the use of equipment.

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-22 22:04

- Views:

What are the advantages of plasma cleaning technology What materials can be processed:

There are three forms of matter existing around us: solid, liquid and gaseous. Plasma is usually called the fourth state of matter. Ordinary gas is composed of electrically neutral molecules or atoms. Ionized gas is a collection of electrons, ions, atoms, molecules or free radical particles. The total number of positive and negative charges is always equal in value.

Based on this plasma composition, ionized gas exhibits the following two properties:

Based on this plasma composition, ionized gas exhibits the following two properties:

1. Ionized gas is a conductive fluid that can maintain electrical neutrality on a macro scale comparable to the volume of gas.

2. There is a Coulomb force between the charged particles of the ionized gas, which causes the various overall motion behaviors of the charged particle swarm to be affected and dominated by the magnetic field.

There are many ways to generate plasma. Natural methods exist between celestial bodies in the universe and the upper atmosphere. Artificial methods-generally discharge methods, radiation methods, vacuum ultraviolet light, lasers, combustion, shock waves, field ionization, etc.

Discharge methods include DC discharge, low-frequency discharge, high-frequency discharge, microwave, and induction methods. We use 13.56MHz high-frequency power supply to generate glow discharge in the equipment, and realize various reaction mechanisms in different reaction chamber conditions, thereby producing different process effects.

The important advantage of plasma cleaning technology lies in its versatility. It can be used for surface activation, cleaning, etching and deposition of a variety of materials.

Why use plasma cleaning technology? This process directly applies a high-energy plasma stream to the surface to be cleaned to achieve the purpose of plasma cleaning. Choosing different gas types and ratios can meet many plasma cleaning requirements.

For example, oxygen plasma can be used to oxidize organic deposits; inert argon plasma can be used to mechanically wash away particle contamination; hydrogen plasma can eliminate metal surface oxidation and so on.

The application of plasma cleaning technology to clean organic matter on the surfaces of metals, ceramics and plastics greatly enhances the adhesion and bonding force on the surfaces of these materials.

With the deepening of the research on this technology, its application has become more and more extensive. In the electronics field, this technology can be used for cleaning and etching of hybrid circuits, PCB boards, SMT, BGA, lead frames and flat panel displays; in the medical field, this technology should also be used to improve various catheters, ultra-fine catheters, and filters. Key indicators such as smoothness and wettability of medical devices such as sensors.

In the large-scale integrated circuit and discrete device industries, plasma cleaning technology is generally used in the following key steps:

1. De-glue, treat the silicon wafer with oxygen plasma to remove the photoresist;

2. Plasma cleaning of the device substrate before metallization;

3. Plasma cleaning before bonding the hybrid circuit;

4. Plasma cleaning before bonding;

5. Plasma cleaning before capping the metalized ceramic tube;

6. The controllability and repeatability of the plasma cleaning technology process is reflected in the advantages of economy, environmental protection, high efficiency, high reliability and easy operation in the use of equipment.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen