Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Plasma cleaner is used for wafer-level packaging surface treatment to improve product reliability

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-08-29

- Views:

(Summary description)Plasma cleaner is used for wafer-level packaging surface treatment to improve product reliability: The purpose of the pre-treatment of wafer-level packaging is to remove surface inorganics, reduce oxidation, increase copper surface roughness, and improve product reliability. In industry, plasma cleaners are generally used for ultra-clean cleaning and surface roughening treatment. Wafer Level Package (WLP, WaferLevelPackage) is an advanced chip packaging method, which refers to packaging and testing directly on the wafer after the production of the entire wafer is completed, and then the entire wafer is cut into one Die; the electrical connection part uses a copper bump (CopperBump) instead of wire bonding (WireBond), so there is no need for wire bonding or glue filling process. What are the advantages of using a plasma cleaner for wafer-level packaging surface treatment? The editor will introduce to you. Due to production capacity requirements, vacuum reaction chamber, electrode structure, air flow distribution, water cooling device, uniformity and other factors, there are obvious differences in the design of plasma cleaning machines. Why do we have to choose a plasma cleaner for wafer-level package surface treatment? The reason is simple: the remaining photoresist after the chip is manufactured cannot be cleaned by wet cleaning, but can only be removed by plasma. In addition, since the thickness of the photoresist cannot be determined, it is necessary to adjust the corresponding process parameters through a number of experiments to achieve a very good processing effect. If you are interested in the plasma cleaning machine or want to know more details, please click Chengfeng Zhizao online customer service, Chengfeng Zhizao is waiting for your call!

Plasma cleaner is used for wafer-level packaging surface treatment to improve product reliability

(Summary description)Plasma cleaner is used for wafer-level packaging surface treatment to improve product reliability:

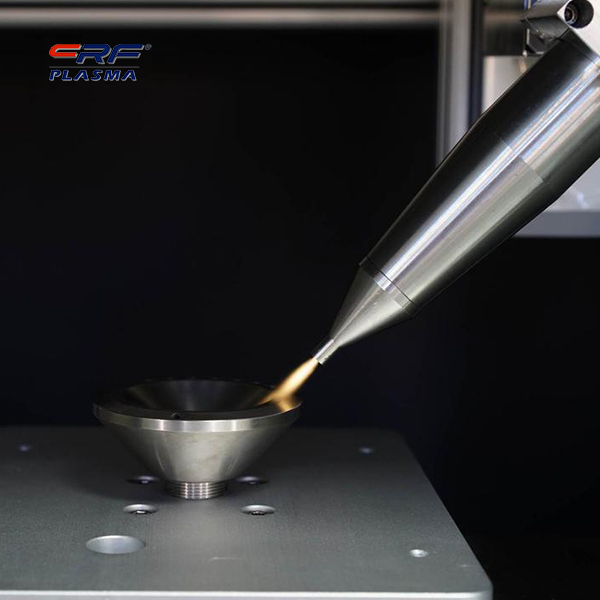

The purpose of the pre-treatment of wafer-level packaging is to remove surface inorganics, reduce oxidation, increase copper surface roughness, and improve product reliability. In industry, plasma cleaners are generally used for ultra-clean cleaning and surface roughening treatment.

Wafer Level Package (WLP, WaferLevelPackage) is an advanced chip packaging method, which refers to packaging and testing directly on the wafer after the production of the entire wafer is completed, and then the entire wafer is cut into one Die; the electrical connection part uses a copper bump (CopperBump) instead of wire bonding (WireBond), so there is no need for wire bonding or glue filling process. What are the advantages of using a plasma cleaner for wafer-level packaging surface treatment? The editor will introduce to you.

Due to production capacity requirements, vacuum reaction chamber, electrode structure, air flow distribution, water cooling device, uniformity and other factors, there are obvious differences in the design of plasma cleaning machines.

Why do we have to choose a plasma cleaner for wafer-level package surface treatment? The reason is simple: the remaining photoresist after the chip is manufactured cannot be cleaned by wet cleaning, but can only be removed by plasma. In addition, since the thickness of the photoresist cannot be determined, it is necessary to adjust the corresponding process parameters through a number of experiments to achieve a very good processing effect.

If you are interested in the plasma cleaning machine or want to know more details, please click Chengfeng Zhizao online customer service, Chengfeng Zhizao is waiting for your call!

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-08-29 21:24

- Views:

Plasma cleaner is used for wafer-level packaging surface treatment to improve product reliability:

The purpose of the pre-treatment of wafer-level packaging is to remove surface inorganics, reduce oxidation, increase copper surface roughness, and improve product reliability. In industry, plasma cleaners are generally used for ultra-clean cleaning and surface roughening treatment.

Wafer Level Package (WLP, WaferLevelPackage) is an advanced chip packaging method, which refers to packaging and testing directly on the wafer after the production of the entire wafer is completed, and then the entire wafer is cut into one Die; the electrical connection part uses a copper bump (CopperBump) instead of wire bonding (WireBond), so there is no need for wire bonding or glue filling process. What are the advantages of using a plasma cleaner for wafer-level packaging surface treatment? The editor will introduce to you.

Due to production capacity requirements, vacuum reaction chamber, electrode structure, air flow distribution, water cooling device, uniformity and other factors, there are obvious differences in the design of plasma cleaning machines.

Due to production capacity requirements, vacuum reaction chamber, electrode structure, air flow distribution, water cooling device, uniformity and other factors, there are obvious differences in the design of plasma cleaning machines.

Why do we have to choose a plasma cleaner for wafer-level package surface treatment? The reason is simple: the remaining photoresist after the chip is manufactured cannot be cleaned by wet cleaning, but can only be removed by plasma. In addition, since the thickness of the photoresist cannot be determined, it is necessary to adjust the corresponding process parameters through a number of experiments to achieve a very good processing effect.

If you are interested in the plasma cleaning machine or want to know more details, please click Chengfeng Zhizao online customer service, Chengfeng Zhizao is waiting for your call!

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen