Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

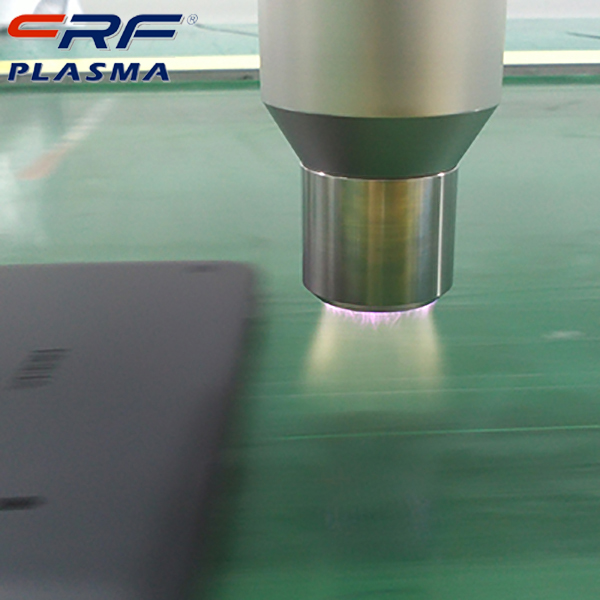

Application research on plasma treatment technology of plasma cleaner in microwave printed circuit board

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-09-01

- Views:

(Summary description)Application research on plasma treatment technology of plasma cleaner in microwave printed circuit board: PTFE has excellent dielectric properties in a wide frequency range, as well as good temperature and wear resistance and chemical resistance, so it is widely used in high-frequency components and seals, such as microwave printed board substrates coated with fluorine Sealing ring, etc. However, due to the low surface energy of PTFE and its very stable chemical properties, it brings great difficulties to the production process of parts, such as metalized surface coating and bonding, and other processing operations must be surface treated first. , Otherwise it is difficult to process or poor reliability after processing. Plasma cleaner plasma is an ionized material, it is a state of matter containing ionic electrons and free radicals. Plasma includes high-temperature plasma and low-temperature plasma, and low-temperature plasma is generally used in plasma processing technology. When polymer materials undergo plasma treatment with plasma cleaners, the surface activation process can actually include two parts. On the one hand, gas particles accelerated by an electric field hit the surface of the material at a high speed, causing plasma etching to make the polymer material The crystal morphology of the surface has changed, which is a physical aspect. On the other hand, the impact of gas on the surface of the material causes a chemical reaction, which generates free radicals on the surface of the material, introduces unsaturated bonds of polar groups and a cross-linked layer, and changes the molecular structure of the surface layer of the material. This is a chemical effect. Both effects can activate the surface of polymer materials to increase wettability, thereby improving the adhesiveness, dyeability and printability of polymer materials. But according to analysis, the effect of chemical action on the surface condition of the material is higher than that of physical action. The characteristic of the plasma treatment technology of the plasma cleaner is that the treatment is concentrated on the superficial layer of the material, so it does not change the bulk properties of the material to be treated. The quality of the hole wall and the pull-out strength of the metallized holes of the PTFE microwave printed board after the plasma treatment technology of the plasma cleaner meets the requirements of the relevant standards. The PTFE microwave printed board is attached after the three-proof coating The focus test is less than level 2, and the film layer is uniform and continuous. These show that the plasma treatment technology has unique advantages in the hole metallization pretreatment and the three-proof coating pretreatment of the PTFE microwave printed board, and it has the advantages of flexible construction, pollution-free, low cost, short treatment cycle, and application. It has the advantages of wide range and low requirements for operators, and is suitable for mass production. Therefore, it has good application prospects in the manufacture of PTFE microwave printed boards.

Application research on plasma treatment technology of plasma cleaner in microwave printed circuit board

(Summary description)Application research on plasma treatment technology of plasma cleaner in microwave printed circuit board:

PTFE has excellent dielectric properties in a wide frequency range, as well as good temperature and wear resistance and chemical resistance, so it is widely used in high-frequency components and seals, such as microwave printed board substrates coated with fluorine Sealing ring, etc.

However, due to the low surface energy of PTFE and its very stable chemical properties, it brings great difficulties to the production process of parts, such as metalized surface coating and bonding, and other processing operations must be surface treated first. , Otherwise it is difficult to process or poor reliability after processing. Plasma cleaner plasma is an ionized material, it is a state of matter containing ionic electrons and free radicals. Plasma includes high-temperature plasma and low-temperature plasma, and low-temperature plasma is generally used in plasma processing technology.

When polymer materials undergo plasma treatment with plasma cleaners, the surface activation process can actually include two parts. On the one hand, gas particles accelerated by an electric field hit the surface of the material at a high speed, causing plasma etching to make the polymer material The crystal morphology of the surface has changed, which is a physical aspect.

On the other hand, the impact of gas on the surface of the material causes a chemical reaction, which generates free radicals on the surface of the material, introduces unsaturated bonds of polar groups and a cross-linked layer, and changes the molecular structure of the surface layer of the material. This is a chemical effect.

Both effects can activate the surface of polymer materials to increase wettability, thereby improving the adhesiveness, dyeability and printability of polymer materials.

But according to analysis, the effect of chemical action on the surface condition of the material is higher than that of physical action. The characteristic of the plasma treatment technology of the plasma cleaner is that the treatment is concentrated on the superficial layer of the material, so it does not change the bulk properties of the material to be treated.

The quality of the hole wall and the pull-out strength of the metallized holes of the PTFE microwave printed board after the plasma treatment technology of the plasma cleaner meets the requirements of the relevant standards. The PTFE microwave printed board is attached after the three-proof coating The focus test is less than level 2, and the film layer is uniform and continuous.

These show that the plasma treatment technology has unique advantages in the hole metallization pretreatment and the three-proof coating pretreatment of the PTFE microwave printed board, and it has the advantages of flexible construction, pollution-free, low cost, short treatment cycle, and application. It has the advantages of wide range and low requirements for operators, and is suitable for mass production. Therefore, it has good application prospects in the manufacture of PTFE microwave printed boards.

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-09-01 20:35

- Views:

Application research on plasma treatment technology of plasma cleaner in microwave printed circuit board:

PTFE has excellent dielectric properties in a wide frequency range, as well as good temperature and wear resistance and chemical resistance, so it is widely used in high-frequency components and seals, such as microwave printed board substrates coated with fluorine Sealing ring, etc.

However, due to the low surface energy of PTFE and its very stable chemical properties, it brings great difficulties to the production process of parts, such as metalized surface coating and bonding, and other processing operations must be surface treated first. , Otherwise it is difficult to process or poor reliability after processing. Plasma cleaner plasma is an ionized material, it is a state of matter containing ionic electrons and free radicals. Plasma includes high-temperature plasma and low-temperature plasma, and low-temperature plasma is generally used in plasma processing technology.

When polymer materials undergo plasma treatment with plasma cleaners, the surface activation process can actually include two parts. On the one hand, gas particles accelerated by an electric field hit the surface of the material at a high speed, causing plasma etching to make the polymer material The crystal morphology of the surface has changed, which is a physical aspect.

On the other hand, the impact of gas on the surface of the material causes a chemical reaction, which generates free radicals on the surface of the material, introduces unsaturated bonds of polar groups and a cross-linked layer, and changes the molecular structure of the surface layer of the material. This is a chemical effect.

On the other hand, the impact of gas on the surface of the material causes a chemical reaction, which generates free radicals on the surface of the material, introduces unsaturated bonds of polar groups and a cross-linked layer, and changes the molecular structure of the surface layer of the material. This is a chemical effect.

Both effects can activate the surface of polymer materials to increase wettability, thereby improving the adhesiveness, dyeability and printability of polymer materials.

But according to analysis, the effect of chemical action on the surface condition of the material is higher than that of physical action. The characteristic of the plasma treatment technology of the plasma cleaner is that the treatment is concentrated on the superficial layer of the material, so it does not change the bulk properties of the material to be treated.

The quality of the hole wall and the pull-out strength of the metallized holes of the PTFE microwave printed board after the plasma treatment technology of the plasma cleaner meets the requirements of the relevant standards. The PTFE microwave printed board is attached after the three-proof coating The focus test is less than level 2, and the film layer is uniform and continuous.

These show that the plasma treatment technology has unique advantages in the hole metallization pretreatment and the three-proof coating pretreatment of the PTFE microwave printed board, and it has the advantages of flexible construction, pollution-free, low cost, short treatment cycle, and application. It has the advantages of wide range and low requirements for operators, and is suitable for mass production. Therefore, it has good application prospects in the manufacture of PTFE microwave printed boards.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen