Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Plasma processor low temperature plasma technology and its application in plastic packaging

- Categories:Company Dynamics

- Author:

- Origin:

- Time of issue:2021-08-28

- Views:

(Summary description)Plasma processor low temperature plasma technology and its application in plastic packaging: The technological advancement of the plastics industry has made the functional development trend of plastic packaging films increasingly obvious, and high-requirement and high-tech plastic packaging films are becoming the pillar industry and R&D targets in the industry. The plastic packaging industry is an important part of the packaging industry. The plastic packaging industry accounts for about 28% of my country's entire packaging industry. At the same time, the plastic packaging industry is also one of the rapidly developing fields in China's plastics industry. The poor adhesion of the ink on the surface of the plastic film is a relatively large problem in the printing process of the plastic film, which will lead to greater losses. The main reason for this phenomenon is that the surface tension of the plastic film is insufficient, and the wettability of the ink is not good enough. Therefore, it is particularly important to increase the surface tension of the plastic film, enhance the wetting performance of the ink, and improve the printing adaptability of the plastic film. The use of plasma processor low-temperature plasma technology to treat the surface of the plastic film can significantly improve its surface free energy and change the surface wettability of the material. The energy of particles in low-temperature plasma is generally higher than many bond energies of polymer. Therefore, when electrons or ions in the plasma reach the surface of the medium, some chemical bonds in the polymer can be easily opened to make them become free radicals. , Such as CH, OH, CN, CS, COOH, etc., even break and decompose the molecular bonds of macromolecules of organic materials, thereby accelerating the activation of the surface of the material and changing its surface activity. For the plasma processor low-temperature plasma of non-polymeric reactive gases like O2, N2, etc., a large number of free radicals can be directly generated through oxidation reaction, and a large number of oxygen-containing groups can be combined on the macromolecular chain by means of the chain reaction of free radicals. Some of the chemical bonds of carbon atoms in the surface molecules of materials such as PE and PET are broken by active ions and become free radicals of carbon. Carbon free radicals combine with oxygen free radicals to generate CO or CO2 gas, which is extracted, leaving a large number of vacancies in the film surface molecules, thereby generating a large number of "micropits" and "micro grooves", making the surface rough and increasing the film and Mechanical interlocking between inks. On the other hand, for non-reactive gases such as ArHe or non-reactive gases, plasma processor plasma treatment on the surface of the plastic film can increase the content of polar groups, increase the surface energy and roughness of the plastic film, thereby increasing The wettability and adhesion of the ink on the plastic surface improve the printability of the plastic film. Insufficient film adhesion often occurs in the composite process, which affects the composite processing. The surface wettability of the plastic film not only affects the printability, but also has a close relationship with the difficulty of bonding and coating. The use of low-temperature plasma technology to act on the surface of the plastic film increases the surface activity of the film. This activated surface is easily combined with other materials, which is beneficial to the coating of the adhesive and enhances the composite fastness of the film. The huge printing and packaging industry provides a broad platform for the development of plasma processor low-temperature plasma technology. The continuous maturation of low-temperature plasma plastic film modification technology and the promotion of industrialization will bring us higher quality food and beverage plastic packaging. From the standpoint of sustainable development and environmental protection, more and more attention will be paid to low-temperature plasma technology that can realize high-functionality and high-value-added processing.

Plasma processor low temperature plasma technology and its application in plastic packaging

(Summary description)Plasma processor low temperature plasma technology and its application in plastic packaging:

The technological advancement of the plastics industry has made the functional development trend of plastic packaging films increasingly obvious, and high-requirement and high-tech plastic packaging films are becoming the pillar industry and R&D targets in the industry. The plastic packaging industry is an important part of the packaging industry. The plastic packaging industry accounts for about 28% of my country's entire packaging industry. At the same time, the plastic packaging industry is also one of the rapidly developing fields in China's plastics industry.

The poor adhesion of the ink on the surface of the plastic film is a relatively large problem in the printing process of the plastic film, which will lead to greater losses. The main reason for this phenomenon is that the surface tension of the plastic film is insufficient, and the wettability of the ink is not good enough. Therefore, it is particularly important to increase the surface tension of the plastic film, enhance the wetting performance of the ink, and improve the printing adaptability of the plastic film.

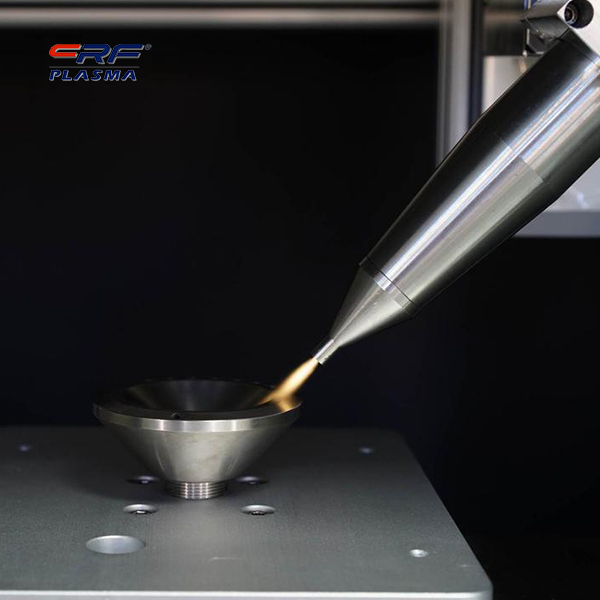

The use of plasma processor low-temperature plasma technology to treat the surface of the plastic film can significantly improve its surface free energy and change the surface wettability of the material. The energy of particles in low-temperature plasma is generally higher than many bond energies of polymer. Therefore, when electrons or ions in the plasma reach the surface of the medium, some chemical bonds in the polymer can be easily opened to make them become free radicals. , Such as CH, OH, CN, CS, COOH, etc., even break and decompose the molecular bonds of macromolecules of organic materials, thereby accelerating the activation of the surface of the material and changing its surface activity.

For the plasma processor low-temperature plasma of non-polymeric reactive gases like O2, N2, etc., a large number of free radicals can be directly generated through oxidation reaction, and a large number of oxygen-containing groups can be combined on the macromolecular chain by means of the chain reaction of free radicals. Some of the chemical bonds of carbon atoms in the surface molecules of materials such as PE and PET are broken by active ions and become free radicals of carbon. Carbon free radicals combine with oxygen free radicals to generate CO or CO2 gas, which is extracted, leaving a large number of vacancies in the film surface molecules, thereby generating a large number of "micropits" and "micro grooves", making the surface rough and increasing the film and Mechanical interlocking between inks.

On the other hand, for non-reactive gases such as ArHe or non-reactive gases, plasma processor plasma treatment on the surface of the plastic film can increase the content of polar groups, increase the surface energy and roughness of the plastic film, thereby increasing The wettability and adhesion of the ink on the plastic surface improve the printability of the plastic film.

Insufficient film adhesion often occurs in the composite process, which affects the composite processing. The surface wettability of the plastic film not only affects the printability, but also has a close relationship with the difficulty of bonding and coating. The use of low-temperature plasma technology to act on the surface of the plastic film increases the surface activity of the film. This activated surface is easily combined with other materials, which is beneficial to the coating of the adhesive and enhances the composite fastness of the film.

The huge printing and packaging industry provides a broad platform for the development of plasma processor low-temperature plasma technology. The continuous maturation of low-temperature plasma plastic film modification technology and the promotion of industrialization will bring us higher quality food and beverage plastic packaging. From the standpoint of sustainable development and environmental protection, more and more attention will be paid to low-temperature plasma technology that can realize high-functionality and high-value-added processing.

- Categories:Company Dynamics

- Author:

- Origin:

- Time of issue:2021-08-28 22:48

- Views:

Plasma processor low temperature plasma technology and its application in plastic packaging:

The technological advancement of the plastics industry has made the functional development trend of plastic packaging films increasingly obvious, and high-requirement and high-tech plastic packaging films are becoming the pillar industry and R&D targets in the industry. The plastic packaging industry is an important part of the packaging industry. The plastic packaging industry accounts for about 28% of my country's entire packaging industry. At the same time, the plastic packaging industry is also one of the rapidly developing fields in China's plastics industry.

The poor adhesion of the ink on the surface of the plastic film is a relatively large problem in the printing process of the plastic film, which will lead to greater losses. The main reason for this phenomenon is that the surface tension of the plastic film is insufficient, and the wettability of the ink is not good enough. Therefore, it is particularly important to increase the surface tension of the plastic film, enhance the wetting performance of the ink, and improve the printing adaptability of the plastic film.

The use of plasma processor low-temperature plasma technology to treat the surface of the plastic film can significantly improve its surface free energy and change the surface wettability of the material. The energy of particles in low-temperature plasma is generally higher than many bond energies of polymer. Therefore, when electrons or ions in the plasma reach the surface of the medium, some chemical bonds in the polymer can be easily opened to make them become free radicals. , Such as CH, OH, CN, CS, COOH, etc., even break and decompose the molecular bonds of macromolecules of organic materials, thereby accelerating the activation of the surface of the material and changing its surface activity.

For the plasma processor low-temperature plasma of non-polymeric reactive gases like O2, N2, etc., a large number of free radicals can be directly generated through oxidation reaction, and a large number of oxygen-containing groups can be combined on the macromolecular chain by means of the chain reaction of free radicals. Some of the chemical bonds of carbon atoms in the surface molecules of materials such as PE and PET are broken by active ions and become free radicals of carbon. Carbon free radicals combine with oxygen free radicals to generate CO or CO2 gas, which is extracted, leaving a large number of vacancies in the film surface molecules, thereby generating a large number of "micropits" and "micro grooves", making the surface rough and increasing the film and Mechanical interlocking between inks.

For the plasma processor low-temperature plasma of non-polymeric reactive gases like O2, N2, etc., a large number of free radicals can be directly generated through oxidation reaction, and a large number of oxygen-containing groups can be combined on the macromolecular chain by means of the chain reaction of free radicals. Some of the chemical bonds of carbon atoms in the surface molecules of materials such as PE and PET are broken by active ions and become free radicals of carbon. Carbon free radicals combine with oxygen free radicals to generate CO or CO2 gas, which is extracted, leaving a large number of vacancies in the film surface molecules, thereby generating a large number of "micropits" and "micro grooves", making the surface rough and increasing the film and Mechanical interlocking between inks.

On the other hand, for non-reactive gases such as ArHe or non-reactive gases, plasma processor plasma treatment on the surface of the plastic film can increase the content of polar groups, increase the surface energy and roughness of the plastic film, thereby increasing The wettability and adhesion of the ink on the plastic surface improve the printability of the plastic film.

Insufficient film adhesion often occurs in the composite process, which affects the composite processing. The surface wettability of the plastic film not only affects the printability, but also has a close relationship with the difficulty of bonding and coating. The use of low-temperature plasma technology to act on the surface of the plastic film increases the surface activity of the film. This activated surface is easily combined with other materials, which is beneficial to the coating of the adhesive and enhances the composite fastness of the film.

The huge printing and packaging industry provides a broad platform for the development of plasma processor low-temperature plasma technology. The continuous maturation of low-temperature plasma plastic film modification technology and the promotion of industrialization will bring us higher quality food and beverage plastic packaging. From the standpoint of sustainable development and environmental protection, more and more attention will be paid to low-temperature plasma technology that can realize high-functionality and high-value-added processing.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen