Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Plasma etching machine technology PTFE plasma hole film interface adhesion performance Surface treatmen

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-03-28

- Views:

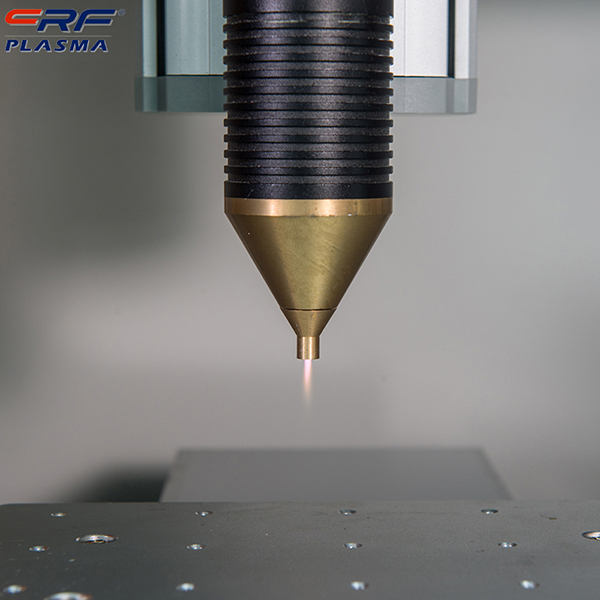

(Summary description)Plasma etching machine technology PTFE plasma hole film interface adhesion performance Surface treatment: PTFE microporous membrane has stable chemical properties, high temperature resistance, corrosion resistance, excellent water resistance and oleophobicity, and has good filtration performance for high temperature, high humidity, high corrosion and machine fluids in special gases, and can be widely used. It is used in dust removal and filtration in metallurgy, chemical industry, coal, cement and other industries. It is a film material of high temperature resistant composite filter material. However, its extremely low surface activity and outstanding non-stick properties make it difficult to compound with substrates, thus limiting its application. Plasma etching machine is also known as plasma etching machine, plasma plane etching machine, plasma surface treatment instrument, plasma cleaning system, etc. Plasma etching machine technology is a common form of dry etching. The principle is that the gas exposed to the electron region forms plasma, generates plasma and releases gas composed of high-energy electrons to form plasma or ions. When bulk atoms are accelerated by an electric field, the force released is sufficient to cling to the material or etch the surface, combining it with the surface driving force. To a certain extent, plasma cleaning is actually a minor phenomenon in the plasma etching process. Dry etching processing equipment includes reaction chamber, power supply, vacuum and other parts. The workpiece is sent to the reaction chamber, and the gases are introduced into the plasma and exchanged. The plasma etching process is essentially an active plasma process. Recently, a shelf form has appeared in the reaction chamber, which the user can move flexibly to configure the appropriate plasma etching method: reactive plasma (RIE), downstream plasma (downstream) and direct plasma (directionplasma) . The power of plasma surface treatment of plasma etching machine technology is not as large as possible. At lower power, the shear strength of the treated film increases with the increase of power, and the strength gradually decreases after reaching the peak value. Inductively Coupled Plasma Etching (ICPE) is a combination of chemical and physical processes. Its basic principle is: under low pressure, the ICP radio frequency power supply is output to the annular coupling coil, and through the coupling glow discharge, the mixed etching gas generates high-density plasma through the coupling glow discharge. The surface of the substrate is bombarded, the chemical bonds of the semiconductor material in the pattern area of the substrate are broken, and volatile substances are generated with the etching gas, which separates the gas from the substrate and is evacuated from the vacuum tube. Under the same conditions, oxygen plasma treatment is more effective than nitrogen plasma treatment. If etching is required, as well as removal of dirt, scum, surface treatment, plasma polymerization, plasma ashing or any other etching application after etching, we can produce safe and reliable plasma etcher technology according to customer requirements. Our company has both traditional plasma etching system and reactive ion etching system, can produce series products, and can also customize special systems for customers. We can provide fast/high quality etch that provides the required uniformity. With the prolongation of the treatment time, the contact angle of the film surface decreased, but within a certain period of time, the contact angle hardly changed. Plasma treatment can be used for a variety of substrates, and complex geometries can also be plasma activated, plasma cleaned, plasma coated, etc. Plasma processing has a low thermal and mechanical load, so low-pressure plasma can also process sensitive materials. The above results show that the use of plasma surface treatment of PTFE has better viscosity, and it is necessary to continuously adjust various treatment parameters to obtain a good treatment process. CRF Chengfengzhi plasma cleaning machine is simple to operate, can set multiple experimental parameters, and can also Store a variety of process parameters, which is very helpful for exploring process parameters. Typical applications of plasma etcher technology are: semiconductor/integrated circuits; gallium nitride; aluminum nitride/gallium nitride; gallium arsenide/aluminum gallium arsenide; gallium arsenide; /InAlAs); silicon; silicon germanium; silicon silicide ceramics (Si3N4); silicon hydrogen bromide; zinc selenide (ZnSe); aluminum; chromium; platinum; molybdenum; niobium; indium; tungsten; indium tin oxide; indium titanium lead acid; plastic/polymer material; polytetrafluoroethylene (PTFE); polyoxymethylene (POM); polybenzimidazole (PBI); polyetheretherketone (PEEK); polyamide (PFA); polyamide (PFA) ; Polyamide etc.

Plasma etching machine technology PTFE plasma hole film interface adhesion performance Surface treatmen

(Summary description)Plasma etching machine technology PTFE plasma hole film interface adhesion performance Surface treatment:

PTFE microporous membrane has stable chemical properties, high temperature resistance, corrosion resistance, excellent water resistance and oleophobicity, and has good filtration performance for high temperature, high humidity, high corrosion and machine fluids in special gases, and can be widely used. It is used in dust removal and filtration in metallurgy, chemical industry, coal, cement and other industries. It is a film material of high temperature resistant composite filter material. However, its extremely low surface activity and outstanding non-stick properties make it difficult to compound with substrates, thus limiting its application. Plasma etching machine is also known as plasma etching machine, plasma plane etching machine, plasma surface treatment instrument, plasma cleaning system, etc. Plasma etching machine technology is a common form of dry etching. The principle is that the gas exposed to the electron region forms plasma, generates plasma and releases gas composed of high-energy electrons to form plasma or ions. When bulk atoms are accelerated by an electric field, the force released is sufficient to cling to the material or etch the surface, combining it with the surface driving force. To a certain extent, plasma cleaning is actually a minor phenomenon in the plasma etching process. Dry etching processing equipment includes reaction chamber, power supply, vacuum and other parts. The workpiece is sent to the reaction chamber, and the gases are introduced into the plasma and exchanged. The plasma etching process is essentially an active plasma process. Recently, a shelf form has appeared in the reaction chamber, which the user can move flexibly to configure the appropriate plasma etching method: reactive plasma (RIE), downstream plasma (downstream) and direct plasma (directionplasma) .

The power of plasma surface treatment of plasma etching machine technology is not as large as possible. At lower power, the shear strength of the treated film increases with the increase of power, and the strength gradually decreases after reaching the peak value. Inductively Coupled Plasma Etching (ICPE) is a combination of chemical and physical processes. Its basic principle is: under low pressure, the ICP radio frequency power supply is output to the annular coupling coil, and through the coupling glow discharge, the mixed etching gas generates high-density plasma through the coupling glow discharge. The surface of the substrate is bombarded, the chemical bonds of the semiconductor material in the pattern area of the substrate are broken, and volatile substances are generated with the etching gas, which separates the gas from the substrate and is evacuated from the vacuum tube.

Under the same conditions, oxygen plasma treatment is more effective than nitrogen plasma treatment. If etching is required, as well as removal of dirt, scum, surface treatment, plasma polymerization, plasma ashing or any other etching application after etching, we can produce safe and reliable plasma etcher technology according to customer requirements. Our company has both traditional plasma etching system and reactive ion etching system, can produce series products, and can also customize special systems for customers. We can provide fast/high quality etch that provides the required uniformity.

With the prolongation of the treatment time, the contact angle of the film surface decreased, but within a certain period of time, the contact angle hardly changed. Plasma treatment can be used for a variety of substrates, and complex geometries can also be plasma activated, plasma cleaned, plasma coated, etc. Plasma processing has a low thermal and mechanical load, so low-pressure plasma can also process sensitive materials.

The above results show that the use of plasma surface treatment of PTFE has better viscosity, and it is necessary to continuously adjust various treatment parameters to obtain a good treatment process. CRF Chengfengzhi plasma cleaning machine is simple to operate, can set multiple experimental parameters, and can also Store a variety of process parameters, which is very helpful for exploring process parameters.

Typical applications of plasma etcher technology are: semiconductor/integrated circuits; gallium nitride; aluminum nitride/gallium nitride; gallium arsenide/aluminum gallium arsenide; gallium arsenide; /InAlAs); silicon; silicon germanium; silicon silicide ceramics (Si3N4); silicon hydrogen bromide; zinc selenide (ZnSe); aluminum; chromium; platinum; molybdenum; niobium; indium; tungsten; indium tin oxide; indium titanium lead acid; plastic/polymer material; polytetrafluoroethylene (PTFE); polyoxymethylene (POM); polybenzimidazole (PBI); polyetheretherketone (PEEK); polyamide (PFA); polyamide (PFA) ; Polyamide etc.

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-03-28 16:39

- Views:

Plasma etching machine technology PTFE plasma hole film interface adhesion performance Surface treatment:

PTFE microporous membrane has stable chemical properties, high temperature resistance, corrosion resistance, excellent water resistance and oleophobicity, and has good filtration performance for high temperature, high humidity, high corrosion and machine fluids in special gases, and can be widely used. It is used in dust removal and filtration in metallurgy, chemical industry, coal, cement and other industries. It is a film material of high temperature resistant composite filter material. However, its extremely low surface activity and outstanding non-stick properties make it difficult to compound with substrates, thus limiting its application. Plasma etching machine is also known as plasma etching machine, plasma plane etching machine, plasma surface treatment instrument, plasma cleaning system, etc. Plasma etching machine technology is a common form of dry etching. The principle is that the gas exposed to the electron region forms plasma, generates plasma and releases gas composed of high-energy electrons to form plasma or ions. When bulk atoms are accelerated by an electric field, the force released is sufficient to cling to the material or etch the surface, combining it with the surface driving force. To a certain extent, plasma cleaning is actually a minor phenomenon in the plasma etching process. Dry etching processing equipment includes reaction chamber, power supply, vacuum and other parts. The workpiece is sent to the reaction chamber, and the gases are introduced into the plasma and exchanged. The plasma etching process is essentially an active plasma process. Recently, a shelf form has appeared in the reaction chamber, which the user can move flexibly to configure the appropriate plasma etching method: reactive plasma (RIE), downstream plasma (downstream) and direct plasma (directionplasma) .

The power of plasma surface treatment of plasma etching machine technology is not as large as possible. At lower power, the shear strength of the treated film increases with the increase of power, and the strength gradually decreases after reaching the peak value. Inductively Coupled Plasma Etching (ICPE) is a combination of chemical and physical processes. Its basic principle is: under low pressure, the ICP radio frequency power supply is output to the annular coupling coil, and through the coupling glow discharge, the mixed etching gas generates high-density plasma through the coupling glow discharge. The surface of the substrate is bombarded, the chemical bonds of the semiconductor material in the pattern area of the substrate are broken, and volatile substances are generated with the etching gas, which separates the gas from the substrate and is evacuated from the vacuum tube.

Under the same conditions, oxygen plasma treatment is more effective than nitrogen plasma treatment. If etching is required, as well as removal of dirt, scum, surface treatment, plasma polymerization, plasma ashing or any other etching application after etching, we can produce safe and reliable plasma etcher technology according to customer requirements. Our company has both traditional plasma etching system and reactive ion etching system, can produce series products, and can also customize special systems for customers. We can provide fast/high quality etch that provides the required uniformity.

Under the same conditions, oxygen plasma treatment is more effective than nitrogen plasma treatment. If etching is required, as well as removal of dirt, scum, surface treatment, plasma polymerization, plasma ashing or any other etching application after etching, we can produce safe and reliable plasma etcher technology according to customer requirements. Our company has both traditional plasma etching system and reactive ion etching system, can produce series products, and can also customize special systems for customers. We can provide fast/high quality etch that provides the required uniformity.

With the prolongation of the treatment time, the contact angle of the film surface decreased, but within a certain period of time, the contact angle hardly changed. Plasma treatment can be used for a variety of substrates, and complex geometries can also be plasma activated, plasma cleaned, plasma coated, etc. Plasma processing has a low thermal and mechanical load, so low-pressure plasma can also process sensitive materials.

The above results show that the use of plasma surface treatment of PTFE has better viscosity, and it is necessary to continuously adjust various treatment parameters to obtain a good treatment process. CRF Chengfengzhi plasma cleaning machine is simple to operate, can set multiple experimental parameters, and can also Store a variety of process parameters, which is very helpful for exploring process parameters.

Typical applications of plasma etcher technology are: semiconductor/integrated circuits; gallium nitride; aluminum nitride/gallium nitride; gallium arsenide/aluminum gallium arsenide; gallium arsenide; /InAlAs); silicon; silicon germanium; silicon silicide ceramics (Si3N4); silicon hydrogen bromide; zinc selenide (ZnSe); aluminum; chromium; platinum; molybdenum; niobium; indium; tungsten; indium tin oxide; indium titanium lead acid; plastic/polymer material; polytetrafluoroethylene (PTFE); polyoxymethylene (POM); polybenzimidazole (PBI); polyetheretherketone (PEEK); polyamide (PFA); polyamide (PFA) ; Polyamide etc.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen