Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

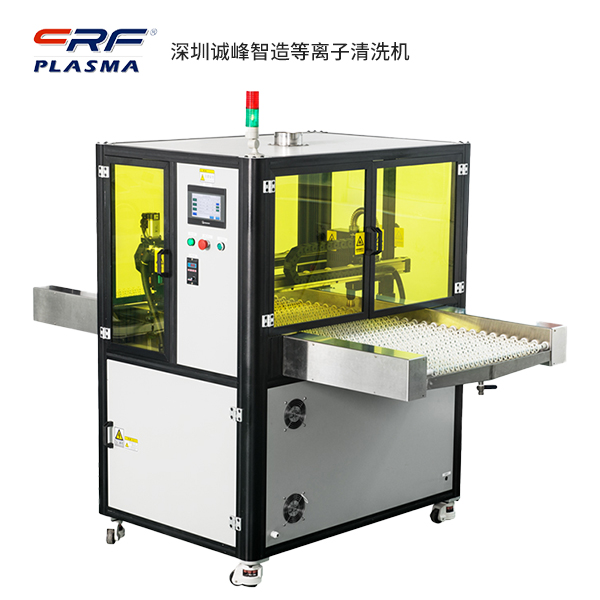

Plasma surface treatment equipment treatment technology solves the difficulty of bonding and stripping in the automotive mobile phone industry

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-03-19

- Views:

(Summary description)Plasma surface treatment equipment treatment technology solves the difficulty of bonding and stripping in the automotive mobile phone industry: Due to the low surface tension of most plastics, many designs in the past used alternative materials. As long as the surface can meet the process requirements of spraying or bonding after being treated by plasma surface treatment equipment, this material is preferred. In recent years, cost and material performance have increasingly become dominant factors in product design, prompting automakers to focus on more plastic varieties. At present, PP, PC, ABS, SMC, various elastomers and various composite materials are widely used in automobile manufacturing. This not only solves the problem of bonding between parts of the same material, but also solves the problem of bonding between parts of different materials, making it difficult for the previous traditional processing methods to meet the requirements of this processing technology. Mobile phones are also one of the indispensable tools in modern life. However, the troublesome thing is that after using the mobile phone for a period of time, it is found that the casing will peel off, wear, or the logo will become more and more clear, which seriously affects the appearance of the mobile phone. The use of plasma surface treatment machine technology has helped mobile phone manufacturers completely solve the above problems. It can be said that plasma surface treatment equipment is a new environmental protection technology on the market, which completely replaces the traditional method of relying on chemicals to surface treatment mobile phone casings. As far as the surface treatment effect is concerned, among the various surface treatment methods at present, the fluorination treatment effect is good, and the bonding ability of the material can be obtained. But this method produces a lot of harmful gases, and the emissions bill is out of reach for most automakers. It is gratifying that the emergence of plasma surface treatment technology has brought new changes to the plastics industry. The whole process can be completed in a short time. The equipment is simple, the operation and maintenance are convenient, only a small amount of gas can replace the expensive detergent, and there is no need to deal with the waste liquid. It can penetrate deep into pores and depressions to complete cleaning tasks. Plasma surface treatment technology can realize the treatment of most solid substances, so its application range is very wide. The mobile phone car shell made by the surface treatment technology of the plasma surface treatment equipment has better wear resistance after being treated by the equipment, which can ensure that the paint will not peel off or grind the paint after long-term use. The use of plasma surface treatment machine technology can clean the residual dust, impurities and oil in the production process. Larger process scale can improve the surface activity of plastics, make the coating film effect very uniform, and the coating film bonding effect is better. Layer connections are stronger.

Plasma surface treatment equipment treatment technology solves the difficulty of bonding and stripping in the automotive mobile phone industry

(Summary description)Plasma surface treatment equipment treatment technology solves the difficulty of bonding and stripping in the automotive mobile phone industry:

Due to the low surface tension of most plastics, many designs in the past used alternative materials. As long as the surface can meet the process requirements of spraying or bonding after being treated by plasma surface treatment equipment, this material is preferred. In recent years, cost and material performance have increasingly become dominant factors in product design, prompting automakers to focus on more plastic varieties. At present, PP, PC, ABS, SMC, various elastomers and various composite materials are widely used in automobile manufacturing. This not only solves the problem of bonding between parts of the same material, but also solves the problem of bonding between parts of different materials, making it difficult for the previous traditional processing methods to meet the requirements of this processing technology.

Mobile phones are also one of the indispensable tools in modern life. However, the troublesome thing is that after using the mobile phone for a period of time, it is found that the casing will peel off, wear, or the logo will become more and more clear, which seriously affects the appearance of the mobile phone. The use of plasma surface treatment machine technology has helped mobile phone manufacturers completely solve the above problems. It can be said that plasma surface treatment equipment is a new environmental protection technology on the market, which completely replaces the traditional method of relying on chemicals to surface treatment mobile phone casings.

As far as the surface treatment effect is concerned, among the various surface treatment methods at present, the fluorination treatment effect is good, and the bonding ability of the material can be obtained. But this method produces a lot of harmful gases, and the emissions bill is out of reach for most automakers.

It is gratifying that the emergence of plasma surface treatment technology has brought new changes to the plastics industry. The whole process can be completed in a short time. The equipment is simple, the operation and maintenance are convenient, only a small amount of gas can replace the expensive detergent, and there is no need to deal with the waste liquid. It can penetrate deep into pores and depressions to complete cleaning tasks. Plasma surface treatment technology can realize the treatment of most solid substances, so its application range is very wide.

The mobile phone car shell made by the surface treatment technology of the plasma surface treatment equipment has better wear resistance after being treated by the equipment, which can ensure that the paint will not peel off or grind the paint after long-term use. The use of plasma surface treatment machine technology can clean the residual dust, impurities and oil in the production process. Larger process scale can improve the surface activity of plastics, make the coating film effect very uniform, and the coating film bonding effect is better. Layer connections are stronger.

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-03-19 21:40

- Views:

Plasma surface treatment equipment treatment technology solves the difficulty of bonding and stripping in the automotive mobile phone industry:

Due to the low surface tension of most plastics, many designs in the past used alternative materials. As long as the surface can meet the process requirements of spraying or bonding after being treated by plasma surface treatment equipment, this material is preferred. In recent years, cost and material performance have increasingly become dominant factors in product design, prompting automakers to focus on more plastic varieties. At present, PP, PC, ABS, SMC, various elastomers and various composite materials are widely used in automobile manufacturing. This not only solves the problem of bonding between parts of the same material, but also solves the problem of bonding between parts of different materials, making it difficult for the previous traditional processing methods to meet the requirements of this processing technology.

Mobile phones are also one of the indispensable tools in modern life. However, the troublesome thing is that after using the mobile phone for a period of time, it is found that the casing will peel off, wear, or the logo will become more and more clear, which seriously affects the appearance of the mobile phone. The use of plasma surface treatment machine technology has helped mobile phone manufacturers completely solve the above problems. It can be said that plasma surface treatment equipment is a new environmental protection technology on the market, which completely replaces the traditional method of relying on chemicals to surface treatment mobile phone casings.

As far as the surface treatment effect is concerned, among the various surface treatment methods at present, the fluorination treatment effect is good, and the bonding ability of the material can be obtained. But this method produces a lot of harmful gases, and the emissions bill is out of reach for most automakers.

It is gratifying that the emergence of plasma surface treatment technology has brought new changes to the plastics industry. The whole process can be completed in a short time. The equipment is simple, the operation and maintenance are convenient, only a small amount of gas can replace the expensive detergent, and there is no need to deal with the waste liquid. It can penetrate deep into pores and depressions to complete cleaning tasks. Plasma surface treatment technology can realize the treatment of most solid substances, so its application range is very wide.

It is gratifying that the emergence of plasma surface treatment technology has brought new changes to the plastics industry. The whole process can be completed in a short time. The equipment is simple, the operation and maintenance are convenient, only a small amount of gas can replace the expensive detergent, and there is no need to deal with the waste liquid. It can penetrate deep into pores and depressions to complete cleaning tasks. Plasma surface treatment technology can realize the treatment of most solid substances, so its application range is very wide.

The mobile phone car shell made by the surface treatment technology of the plasma surface treatment equipment has better wear resistance after being treated by the equipment, which can ensure that the paint will not peel off or grind the paint after long-term use. The use of plasma surface treatment machine technology can clean the residual dust, impurities and oil in the production process. Larger process scale can improve the surface activity of plastics, make the coating film effect very uniform, and the coating film bonding effect is better. Layer connections are stronger.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen