Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

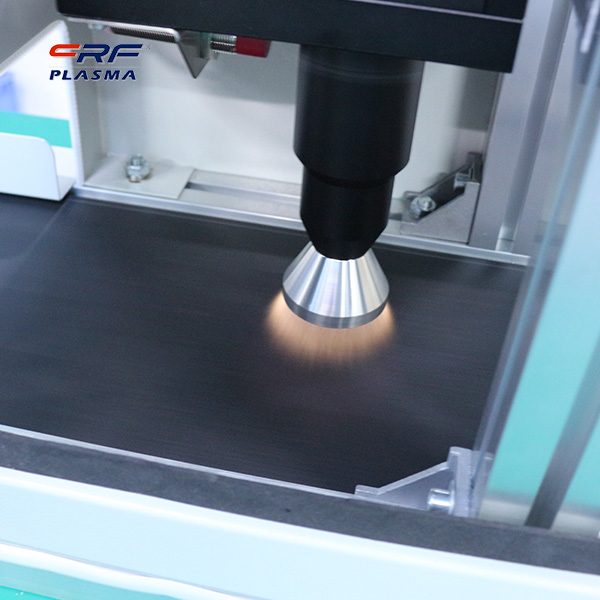

Research on spraying surface modification coating of magnesium alloy plasma cleaner

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-08-03

- Views:

(Summary description)Research on spraying surface modification coating of magnesium alloy plasma cleaner: Magnesium alloys have low density, high specific strength and specific stiffness, and have extremely important application value and broad application prospects in aerospace, transportation, 3C products (communication and computing) and other industries. In addition, magnesium alloy also has good biocompatibility, mechanical compatibility and degradability as a new type of biomedical implant material and has also received extensive attention. Although magnesium alloy has outstanding advantages, it has low wear resistance and poor corrosion resistance, which limits its application to a certain extent. Therefore, improving the corrosion resistance and wear resistance of magnesium alloys under different working conditions is a problem that must be solved to expand its application. The surface modification technology of plasma cleaners can increase the surface hardness, improve corrosion resistance, and enhance wear resistance by adjusting the composition and structure of the modified surface without affecting the strength of the material. Appropriate surface modification treatment of magnesium alloys is of great significance for exerting the performance advantages of magnesium alloys. Plasma cleaning machine spraying technology has the advantages of high productivity, fine coating structure, high bonding strength with substrate, low porosity, wide sources of spraying materials, and low cost, making it suitable for traditional fields such as wear-resistant coatings and corrosion-resistant coatings. The application is more extensive. Due to the differences in physical and chemical properties between the magnesium alloy substrate and the ceramic coating, residual stresses will be generated during the preparation of the coating, which will reduce the bonding strength between the substrate coatings and affect the overall performance. The metal/ceramic gradient coating sprayed by the plasma cleaner uses the metal phase as the transition layer and the ceramic phase as the surface layer, or as the thickness of the coating increases, the content of the ceramic phase gradually increases and the content of the metal phase decreases accordingly, which is a good solution. The problem of the mismatch of metal and ceramic properties. It greatly reduces or eliminates the stress in the coating and improves the bonding strength between the coating and the substrate. Plasma cleaner spraying technology prepares modified coatings on the surface of magnesium alloys, which greatly improves the surface hardness, wear resistance and corrosion resistance of magnesium alloys, and expands the application range of magnesium alloys.

Research on spraying surface modification coating of magnesium alloy plasma cleaner

(Summary description)Research on spraying surface modification coating of magnesium alloy plasma cleaner:

Magnesium alloys have low density, high specific strength and specific stiffness, and have extremely important application value and broad application prospects in aerospace, transportation, 3C products (communication and computing) and other industries. In addition, magnesium alloy also has good biocompatibility, mechanical compatibility and degradability as a new type of biomedical implant material and has also received extensive attention.

Although magnesium alloy has outstanding advantages, it has low wear resistance and poor corrosion resistance, which limits its application to a certain extent. Therefore, improving the corrosion resistance and wear resistance of magnesium alloys under different working conditions is a problem that must be solved to expand its application.

The surface modification technology of plasma cleaners can increase the surface hardness, improve corrosion resistance, and enhance wear resistance by adjusting the composition and structure of the modified surface without affecting the strength of the material. Appropriate surface modification treatment of magnesium alloys is of great significance for exerting the performance advantages of magnesium alloys.

Plasma cleaning machine spraying technology has the advantages of high productivity, fine coating structure, high bonding strength with substrate, low porosity, wide sources of spraying materials, and low cost, making it suitable for traditional fields such as wear-resistant coatings and corrosion-resistant coatings. The application is more extensive.

Due to the differences in physical and chemical properties between the magnesium alloy substrate and the ceramic coating, residual stresses will be generated during the preparation of the coating, which will reduce the bonding strength between the substrate coatings and affect the overall performance.

The metal/ceramic gradient coating sprayed by the plasma cleaner uses the metal phase as the transition layer and the ceramic phase as the surface layer, or as the thickness of the coating increases, the content of the ceramic phase gradually increases and the content of the metal phase decreases accordingly, which is a good solution. The problem of the mismatch of metal and ceramic properties. It greatly reduces or eliminates the stress in the coating and improves the bonding strength between the coating and the substrate.

Plasma cleaner spraying technology prepares modified coatings on the surface of magnesium alloys, which greatly improves the surface hardness, wear resistance and corrosion resistance of magnesium alloys, and expands the application range of magnesium alloys.

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-08-03 22:45

- Views:

Research on spraying surface modification coating of magnesium alloy plasma cleaner:

Magnesium alloys have low density, high specific strength and specific stiffness, and have extremely important application value and broad application prospects in aerospace, transportation, 3C products (communication and computing) and other industries. In addition, magnesium alloy also has good biocompatibility, mechanical compatibility and degradability as a new type of biomedical implant material and has also received extensive attention.

Although magnesium alloy has outstanding advantages, it has low wear resistance and poor corrosion resistance, which limits its application to a certain extent. Therefore, improving the corrosion resistance and wear resistance of magnesium alloys under different working conditions is a problem that must be solved to expand its application.

The surface modification technology of plasma cleaners can increase the surface hardness, improve corrosion resistance, and enhance wear resistance by adjusting the composition and structure of the modified surface without affecting the strength of the material. Appropriate surface modification treatment of magnesium alloys is of great significance for exerting the performance advantages of magnesium alloys.

The surface modification technology of plasma cleaners can increase the surface hardness, improve corrosion resistance, and enhance wear resistance by adjusting the composition and structure of the modified surface without affecting the strength of the material. Appropriate surface modification treatment of magnesium alloys is of great significance for exerting the performance advantages of magnesium alloys.

Plasma cleaning machine spraying technology has the advantages of high productivity, fine coating structure, high bonding strength with substrate, low porosity, wide sources of spraying materials, and low cost, making it suitable for traditional fields such as wear-resistant coatings and corrosion-resistant coatings. The application is more extensive.

Due to the differences in physical and chemical properties between the magnesium alloy substrate and the ceramic coating, residual stresses will be generated during the preparation of the coating, which will reduce the bonding strength between the substrate coatings and affect the overall performance.

The metal/ceramic gradient coating sprayed by the plasma cleaner uses the metal phase as the transition layer and the ceramic phase as the surface layer, or as the thickness of the coating increases, the content of the ceramic phase gradually increases and the content of the metal phase decreases accordingly, which is a good solution. The problem of the mismatch of metal and ceramic properties. It greatly reduces or eliminates the stress in the coating and improves the bonding strength between the coating and the substrate.

Plasma cleaner spraying technology prepares modified coatings on the surface of magnesium alloys, which greatly improves the surface hardness, wear resistance and corrosion resistance of magnesium alloys, and expands the application range of magnesium alloys.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen