Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Today, let’s talk about the plasma technology of different plasma processors

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-12-22

- Views:

(Summary description)Today, let’s talk about the plasma technology of different plasma processors: 1. Vacuum plasma processor technology: This type of plasma is generated in a closed vacuum (10-3 to 10-9 bar). Compared with normal pressure, there are fewer particles per unit volume, which increases the free path length of particles and relatively reduces the collision process. As a result, the tendency of plasma energy to decay is weakened, and it can spread more widely in space. In order to manufacture the vacuum chamber, a powerful air pump is required. Vacuum plasma technology has no linkage connection function. 2. High-voltage plasma processor technology: The high-voltage plasma is generated by a dedicated gas discharge tube. This type of plasma is not important in surface treatment. 3. Corona treatment technology: The corona treatment technology is a physical method that uses high pressure, and is mainly used for thin film processing. The disadvantage of corona pretreatment is that its surface activation ability is low, and the surface effect after treatment is sometimes not uniform. The reverse side of the film can also be treated, which can sometimes be avoided according to process requirements. In addition, the surface tension obtained after corona treatment cannot be kept stable for a long time, and the processed product can only be stored for a limited time. 4. Atmospheric plasma treatment technology: The atmospheric pressure plasma processor technology is a plasma generated under atmospheric pressure conditions. The atmospheric pressure plasma processing technology has low cost and excellent performance. It can be used as a process substitute and process improvement for vacuum plasma and corona plasma, and is widely used. One of the major advantages of atmospheric plasma technology is its online comprehensive performance. This technology can be smoothly integrated into the existing production system as a process criterion.

Today, let’s talk about the plasma technology of different plasma processors

(Summary description)Today, let’s talk about the plasma technology of different plasma processors:

1. Vacuum plasma processor technology:

This type of plasma is generated in a closed vacuum (10-3 to 10-9 bar). Compared with normal pressure, there are fewer particles per unit volume, which increases the free path length of particles and relatively reduces the collision process. As a result, the tendency of plasma energy to decay is weakened, and it can spread more widely in space. In order to manufacture the vacuum chamber, a powerful air pump is required. Vacuum plasma technology has no linkage connection function.

2. High-voltage plasma processor technology:

The high-voltage plasma is generated by a dedicated gas discharge tube. This type of plasma is not important in surface treatment.

3. Corona treatment technology:

The corona treatment technology is a physical method that uses high pressure, and is mainly used for thin film processing. The disadvantage of corona pretreatment is that its surface activation ability is low, and the surface effect after treatment is sometimes not uniform. The reverse side of the film can also be treated, which can sometimes be avoided according to process requirements. In addition, the surface tension obtained after corona treatment cannot be kept stable for a long time, and the processed product can only be stored for a limited time.

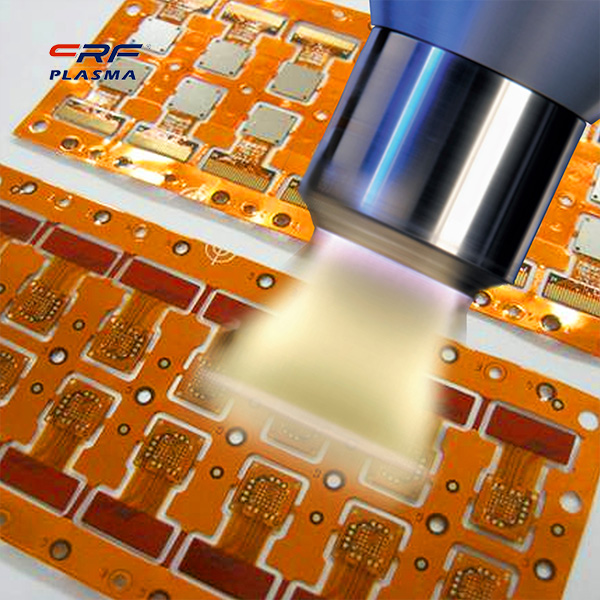

4. Atmospheric plasma treatment technology:

The atmospheric pressure plasma processor technology is a plasma generated under atmospheric pressure conditions. The atmospheric pressure plasma processing technology has low cost and excellent performance. It can be used as a process substitute and process improvement for vacuum plasma and corona plasma, and is widely used. One of the major advantages of atmospheric plasma technology is its online comprehensive performance. This technology can be smoothly integrated into the existing production system as a process criterion.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-12-22 17:12

- Views:

Today, let’s talk about the plasma technology of different plasma processors:

1. Vacuum plasma processor technology:

This type of plasma is generated in a closed vacuum (10-3 to 10-9 bar). Compared with normal pressure, there are fewer particles per unit volume, which increases the free path length of particles and relatively reduces the collision process. As a result, the tendency of plasma energy to decay is weakened, and it can spread more widely in space. In order to manufacture the vacuum chamber, a powerful air pump is required. Vacuum plasma technology has no linkage connection function.

2. High-voltage plasma processor technology:

2. High-voltage plasma processor technology:

The high-voltage plasma is generated by a dedicated gas discharge tube. This type of plasma is not important in surface treatment.

3. Corona treatment technology:

The corona treatment technology is a physical method that uses high pressure, and is mainly used for thin film processing. The disadvantage of corona pretreatment is that its surface activation ability is low, and the surface effect after treatment is sometimes not uniform. The reverse side of the film can also be treated, which can sometimes be avoided according to process requirements. In addition, the surface tension obtained after corona treatment cannot be kept stable for a long time, and the processed product can only be stored for a limited time.

4. Atmospheric plasma treatment technology:

The atmospheric pressure plasma processor technology is a plasma generated under atmospheric pressure conditions. The atmospheric pressure plasma processing technology has low cost and excellent performance. It can be used as a process substitute and process improvement for vacuum plasma and corona plasma, and is widely used. One of the major advantages of atmospheric plasma technology is its online comprehensive performance. This technology can be smoothly integrated into the existing production system as a process criterion.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen