Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Low-temperature plasma surface treatment technology causes changes in the molecular structure of the material surface

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-12-17

- Views:

(Summary description)Low-temperature plasma surface treatment technology causes changes in the molecular structure of the material surface: Low-temperature plasma surface treatment technology refers to the use of high-energy particles in the plasma to bombard the surface of the material to degrade the surface material and increase the surface roughness. Add other active particles, such as oxygen plasma, to the plasma. A method of surface activation by reaction of surface substances. Plasma treatment technology can be used for the surface treatment of fibers, plastics, rubber and composite materials. Low-temperature plasma surface treatment technology provides a method for micro-modification of environmentally friendly and low-cost materials, and the modification process does not require mechanical processing and chemical reagents. Through the low-voltage plasma surface treatment technology, the surface of the material can be cleaned, activated, and etched, and the surface of plastic, metal or ceramic materials can be modified to improve its bonding ability or give new surface properties. Its potential medical value includes improving the hydrophilicity or hydrophobicity of the material surface, reducing surface friction, and improving the barrier properties of the material surface. Low-temperature plasma surface treatment technology is a technology that only changes a few atomic layers on the surface of a polymer to improve its surface adsorption capacity. The modified polyolefin, silica gel and fluoropolymer materials have good bonding properties. According to this similar principle, using plasma surface treatment technology, while obtaining the surface of the material that needs to be transplanted and polymerized, the physical properties of the material itself will not be lost. Plasma surface treatment has no effect on the physical properties of the material, and the position of the material after plasma treatment is generally indistinguishable visually and physically compared with the position not treated by plasma technology. Low-temperature plasma surface treatment is usually a plasma reaction that causes changes in the molecular structure of the surface or the arrangement of atoms on the surface. Plasma treatment can generate highly reactive groups in a low temperature environment, even in an inactive environment such as oxygen or nitrogen. In this process, the plasma also generates high-energy ultraviolet light, which together with rapidly generated ions and electrons provide the energy required to interrupt polymer bonding and produce surface chemical reactions. In this kind of chemical process, only a few atomic layers on the surface of the material participate, and the bulk properties of the polymer are likely to remain deformed. Choosing appropriate reaction gases and process parameters can promote certain specific reactions, thereby forming special polymer attachments and structures. Reactants are often used to make the plasma react with the substrate to generate volatile attachments. The appendages on the surface of the processed material are removed by the vacuum pump due to desorption, and the surface can be etched without further cleaning or neutralization.

Low-temperature plasma surface treatment technology causes changes in the molecular structure of the material surface

(Summary description)Low-temperature plasma surface treatment technology causes changes in the molecular structure of the material surface:

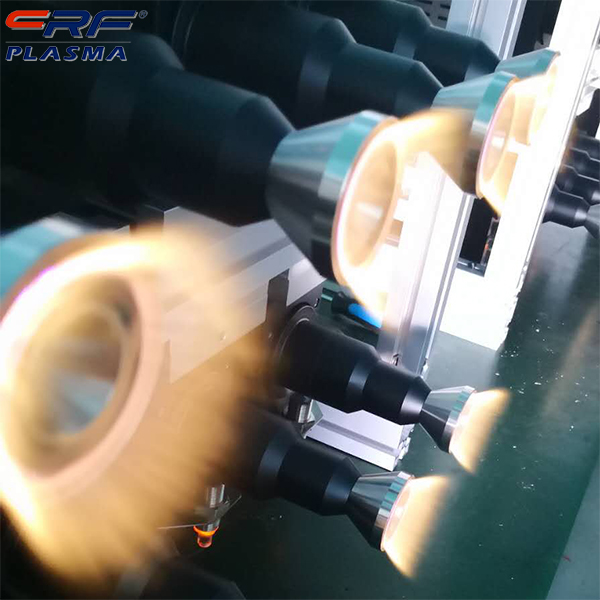

Low-temperature plasma surface treatment technology refers to the use of high-energy particles in the plasma to bombard the surface of the material to degrade the surface material and increase the surface roughness. Add other active particles, such as oxygen plasma, to the plasma. A method of surface activation by reaction of surface substances. Plasma treatment technology can be used for the surface treatment of fibers, plastics, rubber and composite materials.

Low-temperature plasma surface treatment technology provides a method for micro-modification of environmentally friendly and low-cost materials, and the modification process does not require mechanical processing and chemical reagents. Through the low-voltage plasma surface treatment technology, the surface of the material can be cleaned, activated, and etched, and the surface of plastic, metal or ceramic materials can be modified to improve its bonding ability or give new surface properties. Its potential medical value includes improving the hydrophilicity or hydrophobicity of the material surface, reducing surface friction, and improving the barrier properties of the material surface.

Low-temperature plasma surface treatment technology is a technology that only changes a few atomic layers on the surface of a polymer to improve its surface adsorption capacity. The modified polyolefin, silica gel and fluoropolymer materials have good bonding properties. According to this similar principle, using plasma surface treatment technology, while obtaining the surface of the material that needs to be transplanted and polymerized, the physical properties of the material itself will not be lost. Plasma surface treatment has no effect on the physical properties of the material, and the position of the material after plasma treatment is generally indistinguishable visually and physically compared with the position not treated by plasma technology.

Low-temperature plasma surface treatment is usually a plasma reaction that causes changes in the molecular structure of the surface or the arrangement of atoms on the surface. Plasma treatment can generate highly reactive groups in a low temperature environment, even in an inactive environment such as oxygen or nitrogen. In this process, the plasma also generates high-energy ultraviolet light, which together with rapidly generated ions and electrons provide the energy required to interrupt polymer bonding and produce surface chemical reactions. In this kind of chemical process, only a few atomic layers on the surface of the material participate, and the bulk properties of the polymer are likely to remain deformed. Choosing appropriate reaction gases and process parameters can promote certain specific reactions, thereby forming special polymer attachments and structures. Reactants are often used to make the plasma react with the substrate to generate volatile attachments. The appendages on the surface of the processed material are removed by the vacuum pump due to desorption, and the surface can be etched without further cleaning or neutralization.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-12-17 17:18

- Views:

Low-temperature plasma surface treatment technology causes changes in the molecular structure of the material surface:

Low-temperature plasma surface treatment technology refers to the use of high-energy particles in the plasma to bombard the surface of the material to degrade the surface material and increase the surface roughness. Add other active particles, such as oxygen plasma, to the plasma. A method of surface activation by reaction of surface substances. Plasma treatment technology can be used for the surface treatment of fibers, plastics, rubber and composite materials.

Low-temperature plasma surface treatment technology provides a method for micro-modification of environmentally friendly and low-cost materials, and the modification process does not require mechanical processing and chemical reagents. Through the low-voltage plasma surface treatment technology, the surface of the material can be cleaned, activated, and etched, and the surface of plastic, metal or ceramic materials can be modified to improve its bonding ability or give new surface properties. Its potential medical value includes improving the hydrophilicity or hydrophobicity of the material surface, reducing surface friction, and improving the barrier properties of the material surface.

Low-temperature plasma surface treatment technology provides a method for micro-modification of environmentally friendly and low-cost materials, and the modification process does not require mechanical processing and chemical reagents. Through the low-voltage plasma surface treatment technology, the surface of the material can be cleaned, activated, and etched, and the surface of plastic, metal or ceramic materials can be modified to improve its bonding ability or give new surface properties. Its potential medical value includes improving the hydrophilicity or hydrophobicity of the material surface, reducing surface friction, and improving the barrier properties of the material surface.

Low-temperature plasma surface treatment technology is a technology that only changes a few atomic layers on the surface of a polymer to improve its surface adsorption capacity. The modified polyolefin, silica gel and fluoropolymer materials have good bonding properties. According to this similar principle, using plasma surface treatment technology, while obtaining the surface of the material that needs to be transplanted and polymerized, the physical properties of the material itself will not be lost. Plasma surface treatment has no effect on the physical properties of the material, and the position of the material after plasma treatment is generally indistinguishable visually and physically compared with the position not treated by plasma technology.

Low-temperature plasma surface treatment is usually a plasma reaction that causes changes in the molecular structure of the surface or the arrangement of atoms on the surface. Plasma treatment can generate highly reactive groups in a low temperature environment, even in an inactive environment such as oxygen or nitrogen. In this process, the plasma also generates high-energy ultraviolet light, which together with rapidly generated ions and electrons provide the energy required to interrupt polymer bonding and produce surface chemical reactions. In this kind of chemical process, only a few atomic layers on the surface of the material participate, and the bulk properties of the polymer are likely to remain deformed. Choosing appropriate reaction gases and process parameters can promote certain specific reactions, thereby forming special polymer attachments and structures. Reactants are often used to make the plasma react with the substrate to generate volatile attachments. The appendages on the surface of the processed material are removed by the vacuum pump due to desorption, and the surface can be etched without further cleaning or neutralization.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen