Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Research on the plasma hydrophilic treatment of polyolefin synthetic paper by plasma cleaning equipment

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-09-13

- Views:

(Summary description)Research on the plasma hydrophilic treatment of polyolefin synthetic paper by plasma cleaning equipment: Plasma modification is a new method of gas-solid coherent treatment of polymers. It has the advantages of fast, efficient, pollution-free, simple operation, and energy saving. The reaction only involves the shallow surface within 100 nanometers of the fiber without changing the polymer. The performance of the polymer can be given new characteristics. Plasma cleaning equipment has three main effects on fiber surface treatment: etching, surface cross-linking and attracting polar groups. Plasma usually contains high-energy particles. When these high-energy particles act on polyolefin fibers, heating, etching, and free radical reactions occur. These effects can attract temporary hydrophilic groups, but these hydrophilic groups are easy to disappear. In order to maintain the hydrophilic properties of the paper for a long time, a monomer that will have hydrophilicity after plasma treatment is often used ( Such as acrylic) is grafted onto paper fibers. Argon plasma hydrophilization treatment of polyolefin synthetic paper. Since argon is a non-reactive gas, the gas atoms do not directly enter the macromolecular chain on the surface of the polymer material, and will not have an essential impact on the properties of the polymer body. Use plasma cleaner equipment to hydrophilize the paper sample formed by manual sheeting: As the discharge power increases, the absorption performance of polyolefin synthetic paper increases to a certain value and then begins to decrease. This is because when the discharge power is increased, more and more free radicals are activated on the surface of the paper. Under a certain reaction temperature, it triggers an increase in the grafting rate of acrylic acid to polyolefin synthetic paper, and some oxygen-containing groups are produced on the surface of the paper. Groups, these groups can form hydrogen bonds with water molecules, making the contact angle of paper to water smaller. With the further increase of the discharge power, the absorption performance of the paper decreases. This may be due to the increase in the energy of the charged particles, and the cross-linking and etching effect of the plasma on the paper surface dominates, resulting in a decrease in the number of active groups. Absorption properties of polyolefin synthetic paper. The changing trend of rising first and then falling. The height of alkali absorption is also a reflection of the alkali absorption rate, and the alkali absorption rate is another important indicator of the hydrophilicity. The higher the electrolyte retention rate, the better the ability to absorb enough electrolyte. After absorbing the electrolyte, a diaphragm with very fine micropores is formed, and at the same time, the distribution is uniform, which is beneficial to prevent the formation of an electronic conduction path penetrating the diaphragm. At the same time, absorbing electrolyte can prevent the battery diaphragm from drying out and increase the cycle life of the battery. The effect of the processing pressure of the argon plasma cleaner on the absorption performance of the paper can be known, and the absorption performance of the paper increases first and then decreases as the processing pressure increases. In the beginning, the number of argon molecules was relatively small, so the number of charged particles was also limited, and the activation effect was obvious. Therefore, the absorption performance of paper increases rapidly with the increase of acrylic acid grafting rate. When the processing pressure continues to increase, the number of argon molecules increases, but because the power is constant and the energy of the system is constant, a further increase in the working gas pressure will cause the average energy of each particle to decrease, and the number of active particles that are truly ionized will decrease, which affects the activation. Effect, resulting in a decline in the absorption performance of the paper. After the polyolefin synthetic paper is treated by an argon plasma cleaning machine and grafted with acrylic acid, its hydrophilicity is greatly improved, which can meet the alkali absorption performance of battery diaphragm paper.

Research on the plasma hydrophilic treatment of polyolefin synthetic paper by plasma cleaning equipment

(Summary description)Research on the plasma hydrophilic treatment of polyolefin synthetic paper by plasma cleaning equipment:

Plasma modification is a new method of gas-solid coherent treatment of polymers. It has the advantages of fast, efficient, pollution-free, simple operation, and energy saving. The reaction only involves the shallow surface within 100 nanometers of the fiber without changing the polymer. The performance of the polymer can be given new characteristics. Plasma cleaning equipment has three main effects on fiber surface treatment: etching, surface cross-linking and attracting polar groups. Plasma usually contains high-energy particles. When these high-energy particles act on polyolefin fibers, heating, etching, and free radical reactions occur.

These effects can attract temporary hydrophilic groups, but these hydrophilic groups are easy to disappear. In order to maintain the hydrophilic properties of the paper for a long time, a monomer that will have hydrophilicity after plasma treatment is often used ( Such as acrylic) is grafted onto paper fibers. Argon plasma hydrophilization treatment of polyolefin synthetic paper. Since argon is a non-reactive gas, the gas atoms do not directly enter the macromolecular chain on the surface of the polymer material, and will not have an essential impact on the properties of the polymer body.

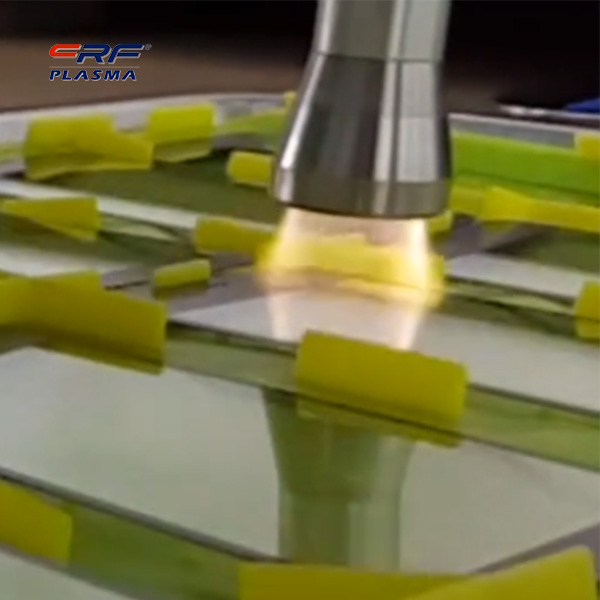

Use plasma cleaner equipment to hydrophilize the paper sample formed by manual sheeting:

As the discharge power increases, the absorption performance of polyolefin synthetic paper increases to a certain value and then begins to decrease. This is because when the discharge power is increased, more and more free radicals are activated on the surface of the paper. Under a certain reaction temperature, it triggers an increase in the grafting rate of acrylic acid to polyolefin synthetic paper, and some oxygen-containing groups are produced on the surface of the paper. Groups, these groups can form hydrogen bonds with water molecules, making the contact angle of paper to water smaller.

With the further increase of the discharge power, the absorption performance of the paper decreases. This may be due to the increase in the energy of the charged particles, and the cross-linking and etching effect of the plasma on the paper surface dominates, resulting in a decrease in the number of active groups. Absorption properties of polyolefin synthetic paper. The changing trend of rising first and then falling.

The height of alkali absorption is also a reflection of the alkali absorption rate, and the alkali absorption rate is another important indicator of the hydrophilicity. The higher the electrolyte retention rate, the better the ability to absorb enough electrolyte. After absorbing the electrolyte, a diaphragm with very fine micropores is formed, and at the same time, the distribution is uniform, which is beneficial to prevent the formation of an electronic conduction path penetrating the diaphragm. At the same time, absorbing electrolyte can prevent the battery diaphragm from drying out and increase the cycle life of the battery.

The effect of the processing pressure of the argon plasma cleaner on the absorption performance of the paper can be known, and the absorption performance of the paper increases first and then decreases as the processing pressure increases. In the beginning, the number of argon molecules was relatively small, so the number of charged particles was also limited, and the activation effect was obvious. Therefore, the absorption performance of paper increases rapidly with the increase of acrylic acid grafting rate.

When the processing pressure continues to increase, the number of argon molecules increases, but because the power is constant and the energy of the system is constant, a further increase in the working gas pressure will cause the average energy of each particle to decrease, and the number of active particles that are truly ionized will decrease, which affects the activation. Effect, resulting in a decline in the absorption performance of the paper. After the polyolefin synthetic paper is treated by an argon plasma cleaning machine and grafted with acrylic acid, its hydrophilicity is greatly improved, which can meet the alkali absorption performance of battery diaphragm paper.

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-09-13 18:36

- Views:

Research on the plasma hydrophilic treatment of polyolefin synthetic paper by plasma cleaning equipment:

Plasma modification is a new method of gas-solid coherent treatment of polymers. It has the advantages of fast, efficient, pollution-free, simple operation, and energy saving. The reaction only involves the shallow surface within 100 nanometers of the fiber without changing the polymer. The performance of the polymer can be given new characteristics. Plasma cleaning equipment has three main effects on fiber surface treatment: etching, surface cross-linking and attracting polar groups. Plasma usually contains high-energy particles. When these high-energy particles act on polyolefin fibers, heating, etching, and free radical reactions occur.

These effects can attract temporary hydrophilic groups, but these hydrophilic groups are easy to disappear. In order to maintain the hydrophilic properties of the paper for a long time, a monomer that will have hydrophilicity after plasma treatment is often used ( Such as acrylic) is grafted onto paper fibers. Argon plasma hydrophilization treatment of polyolefin synthetic paper. Since argon is a non-reactive gas, the gas atoms do not directly enter the macromolecular chain on the surface of the polymer material, and will not have an essential impact on the properties of the polymer body.

Use plasma cleaner equipment to hydrophilize the paper sample formed by manual sheeting:

As the discharge power increases, the absorption performance of polyolefin synthetic paper increases to a certain value and then begins to decrease. This is because when the discharge power is increased, more and more free radicals are activated on the surface of the paper. Under a certain reaction temperature, it triggers an increase in the grafting rate of acrylic acid to polyolefin synthetic paper, and some oxygen-containing groups are produced on the surface of the paper. Groups, these groups can form hydrogen bonds with water molecules, making the contact angle of paper to water smaller.

With the further increase of the discharge power, the absorption performance of the paper decreases. This may be due to the increase in the energy of the charged particles, and the cross-linking and etching effect of the plasma on the paper surface dominates, resulting in a decrease in the number of active groups. Absorption properties of polyolefin synthetic paper. The changing trend of rising first and then falling.

The height of alkali absorption is also a reflection of the alkali absorption rate, and the alkali absorption rate is another important indicator of the hydrophilicity. The higher the electrolyte retention rate, the better the ability to absorb enough electrolyte. After absorbing the electrolyte, a diaphragm with very fine micropores is formed, and at the same time, the distribution is uniform, which is beneficial to prevent the formation of an electronic conduction path penetrating the diaphragm. At the same time, absorbing electrolyte can prevent the battery diaphragm from drying out and increase the cycle life of the battery.

The effect of the processing pressure of the argon plasma cleaner on the absorption performance of the paper can be known, and the absorption performance of the paper increases first and then decreases as the processing pressure increases. In the beginning, the number of argon molecules was relatively small, so the number of charged particles was also limited, and the activation effect was obvious. Therefore, the absorption performance of paper increases rapidly with the increase of acrylic acid grafting rate.

When the processing pressure continues to increase, the number of argon molecules increases, but because the power is constant and the energy of the system is constant, a further increase in the working gas pressure will cause the average energy of each particle to decrease, and the number of active particles that are truly ionized will decrease, which affects the activation. Effect, resulting in a decline in the absorption performance of the paper. After the polyolefin synthetic paper is treated by an argon plasma cleaning machine and grafted with acrylic acid, its hydrophilicity is greatly improved, which can meet the alkali absorption performance of battery diaphragm paper.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen