Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

What are the benefits of plasma equipment pretreatment of engine guard plate before epoxy foaming

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-09-11

- Views:

(Summary description)What are the benefits of plasma equipment pretreatment of engine guard plate before epoxy foaming: The material of the engine guard plate includes hard plastic, steel, aluminum alloy, plastic steel, etc. The foam plastic is usually used for surface pretreatment with plasma equipment before foaming to increase adhesion and reliability. Plasma surface treatment can completely remove dirt, activate the surface, and improve bonding quality. The main function of the engine guard plate is to protect the engine and prolong the service life of the engine. Its materials include hard plastic resin, iron or manganese alloy guard plate, aluminum alloy, plastic steel "alloy" guard plate, etc. Epoxy foaming of engine guard plate is to form good sealing effect, high weather resistance and high reliability requirements. Plasma surface treatment by plasma equipment can completely remove contaminants on the surface of the material, activate the surface, and improve the quality of bonding. Plastics are increasingly used as engine guards, and the main chemical composition of plastics is modified polymers, also known as modified copolymer PP. It has excellent performance, convenient processing, and wide range of uses. Because of its excellent physical properties such as rigidity, elasticity, corrosion resistance, and aging resistance, it is an ideal substitute for non-ferrous metals such as copper, zinc, and aluminum. Function hinders. However, the surface energy of polypropylene material is low, and the reliability of combining it with glue without special primer will be reduced. These glues are expensive to use, and VOC gas will be generated at high temperatures, causing harm to the human body; plasma surface treatment technology is environmentally friendly , Low cost of use and other advantages, more and more attention by engine guard plate manufacturers! Before the plasma treatment of the plasma equipment, the surface energy of PP is low, it is not easy to stick to water, and it is in the shape of water droplets. The surface of PP treated by plasma equipment is enhanced, and the water droplets are easy to spread and spread out completely. The change of water droplets on the surface of the engine guard plate, users report that the adhesive foaming effect has been significantly improved, this process is very worth recommending! The above description of the benefits of plasma surface treatment of the plasma equipment before epoxy foaming of the engine guard plate. Do you have any different opinions or suggestions on this? Welcome to leave a message to communicate and share with us! If you are interested in plasma cleaners or want to know more details, please click Chengfeng Zhizao online customer service consultation, Chengfeng Zhizao is waiting for your call!

What are the benefits of plasma equipment pretreatment of engine guard plate before epoxy foaming

(Summary description)What are the benefits of plasma equipment pretreatment of engine guard plate before epoxy foaming:

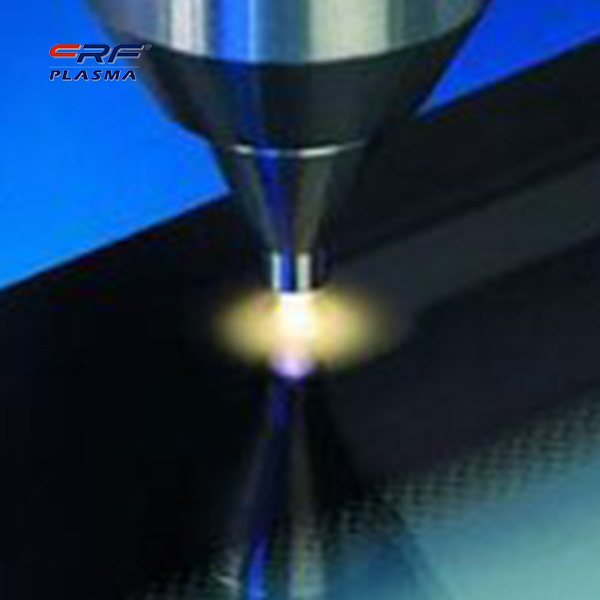

The material of the engine guard plate includes hard plastic, steel, aluminum alloy, plastic steel, etc. The foam plastic is usually used for surface pretreatment with plasma equipment before foaming to increase adhesion and reliability. Plasma surface treatment can completely remove dirt, activate the surface, and improve bonding quality.

The main function of the engine guard plate is to protect the engine and prolong the service life of the engine. Its materials include hard plastic resin, iron or manganese alloy guard plate, aluminum alloy, plastic steel "alloy" guard plate, etc. Epoxy foaming of engine guard plate is to form good sealing effect, high weather resistance and high reliability requirements. Plasma surface treatment by plasma equipment can completely remove contaminants on the surface of the material, activate the surface, and improve the quality of bonding.

Plastics are increasingly used as engine guards, and the main chemical composition of plastics is modified polymers, also known as modified copolymer PP. It has excellent performance, convenient processing, and wide range of uses. Because of its excellent physical properties such as rigidity, elasticity, corrosion resistance, and aging resistance, it is an ideal substitute for non-ferrous metals such as copper, zinc, and aluminum. Function hinders. However, the surface energy of polypropylene material is low, and the reliability of combining it with glue without special primer will be reduced. These glues are expensive to use, and VOC gas will be generated at high temperatures, causing harm to the human body; plasma surface treatment technology is environmentally friendly , Low cost of use and other advantages, more and more attention by engine guard plate manufacturers!

Before the plasma treatment of the plasma equipment, the surface energy of PP is low, it is not easy to stick to water, and it is in the shape of water droplets. The surface of PP treated by plasma equipment is enhanced, and the water droplets are easy to spread and spread out completely. The change of water droplets on the surface of the engine guard plate, users report that the adhesive foaming effect has been significantly improved, this process is very worth recommending!

The above description of the benefits of plasma surface treatment of the plasma equipment before epoxy foaming of the engine guard plate. Do you have any different opinions or suggestions on this? Welcome to leave a message to communicate and share with us!

If you are interested in plasma cleaners or want to know more details, please click Chengfeng Zhizao online customer service consultation, Chengfeng Zhizao is waiting for your call!

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-09-11 22:43

- Views:

What are the benefits of plasma equipment pretreatment of engine guard plate before epoxy foaming:

The material of the engine guard plate includes hard plastic, steel, aluminum alloy, plastic steel, etc. The foam plastic is usually used for surface pretreatment with plasma equipment before foaming to increase adhesion and reliability. Plasma surface treatment can completely remove dirt, activate the surface, and improve bonding quality.

The main function of the engine guard plate is to protect the engine and prolong the service life of the engine. Its materials include hard plastic resin, iron or manganese alloy guard plate, aluminum alloy, plastic steel "alloy" guard plate, etc. Epoxy foaming of engine guard plate is to form good sealing effect, high weather resistance and high reliability requirements. Plasma surface treatment by plasma equipment can completely remove contaminants on the surface of the material, activate the surface, and improve the quality of bonding.

Plastics are increasingly used as engine guards, and the main chemical composition of plastics is modified polymers, also known as modified copolymer PP. It has excellent performance, convenient processing, and wide range of uses. Because of its excellent physical properties such as rigidity, elasticity, corrosion resistance, and aging resistance, it is an ideal substitute for non-ferrous metals such as copper, zinc, and aluminum. Function hinders. However, the surface energy of polypropylene material is low, and the reliability of combining it with glue without special primer will be reduced. These glues are expensive to use, and VOC gas will be generated at high temperatures, causing harm to the human body; plasma surface treatment technology is environmentally friendly , Low cost of use and other advantages, more and more attention by engine guard plate manufacturers!

Plastics are increasingly used as engine guards, and the main chemical composition of plastics is modified polymers, also known as modified copolymer PP. It has excellent performance, convenient processing, and wide range of uses. Because of its excellent physical properties such as rigidity, elasticity, corrosion resistance, and aging resistance, it is an ideal substitute for non-ferrous metals such as copper, zinc, and aluminum. Function hinders. However, the surface energy of polypropylene material is low, and the reliability of combining it with glue without special primer will be reduced. These glues are expensive to use, and VOC gas will be generated at high temperatures, causing harm to the human body; plasma surface treatment technology is environmentally friendly , Low cost of use and other advantages, more and more attention by engine guard plate manufacturers!

Before the plasma treatment of the plasma equipment, the surface energy of PP is low, it is not easy to stick to water, and it is in the shape of water droplets. The surface of PP treated by plasma equipment is enhanced, and the water droplets are easy to spread and spread out completely. The change of water droplets on the surface of the engine guard plate, users report that the adhesive foaming effect has been significantly improved, this process is very worth recommending!

The above description of the benefits of plasma surface treatment of the plasma equipment before epoxy foaming of the engine guard plate. Do you have any different opinions or suggestions on this? Welcome to leave a message to communicate and share with us!

If you are interested in plasma cleaners or want to know more details, please click Chengfeng Zhizao online customer service consultation, Chengfeng Zhizao is waiting for your call!

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen