Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

What role does the low-temperature plasma cleaning machine play in the production and manufacture of power lithium batteries

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-12-10

- Views:

(Summary description)What role does the low-temperature plasma cleaning machine play in the production and manufacture of power lithium batteries: Power lithium battery is a commonly used lithium battery powered by pneumatic tools. This is a clean and environmentally friendly drive power supply. In today's application scenarios, it is widely used in pure electric vehicles, electric trains, electric vehicles and golf carts. In recent years, with the rise of the new energy vehicle sales market, the safety and reliability of power lithium batteries has become a topic of concern and discussion. The reason is not only that the power lithium battery is a key component of the power drive system software, but also that the power lithium battery production process itself has high reliability and reliability requirements. Taking automobile lithium batteries as an example, what role can low-temperature plasma cleaning machines play in the manufacturing process of power lithium batteries? What assistance can be provided for them? In the production process of automobile power lithium battery, the surface treatment of low-temperature plasma cleaning machine is generally carried out from three levels, that is, to improve the lubrication performance of the ceramic film before coating the positive and negative plates; to clean the connecting piece before lithium electric welding; and Improve the surface adhesion of insulating plates, end plates, PET plastic films and other metal composite materials and their insulating materials before external gluing of their lithium battery components. 1. Low-temperature plasma cleaning machine solves the problem of positive and negative two-stage coating before ceramic membrane plasma cleaning machine: The positive and negative stages of the power lithium battery for automobiles are made according to the positive stage of the ceramic film and the battery cathode material. Compared with cleaning with ethanol and other aqueous solutions, plasma cleaning machine treatment will not damage the material itself, and can remove organic matter on the surface of the raw material, improve the lubricity of the film surface, and improve the uniformity, heat resistance and safety factor of the coating. 2. Plasma cleaning before welding: The lithium tab actually refers to the part between the positive and negative stages of the metal material strip that correctly guides the rechargeable battery. It is a point contact type during battery charging and charging and discharging. Whether the surface of the connecting piece is clean or not has a great hazard to the reliability and performance of the electrical connection. Treatment with a plasma cleaner before electric welding can remove organic matter, particles and other residues on the surface of the weld, make the surface of the weld uneven, and improve the quality of steel lap welding. 3. Low-temperature plasma cleaning machine to process the raw rubber of lithium battery components: The lithium battery assembly process is to connect several rechargeable battery modules in series into a series of parallel circuits to produce a lithium battery pack. In order to maintain the safety of the power supply circuit and the insulation layer, during this process, a rechargeable battery must be attached to the outside to improve the safety factor of the application. Prior to this, please use a plasma cleaning machine to clean the insulating plates, end plates, PET film and other parts. Plasma treatment can thoroughly clean the dirt surface, make the surface matte, and improve the adhesion of super glue or super glue.

What role does the low-temperature plasma cleaning machine play in the production and manufacture of power lithium batteries

(Summary description)What role does the low-temperature plasma cleaning machine play in the production and manufacture of power lithium batteries:

Power lithium battery is a commonly used lithium battery powered by pneumatic tools. This is a clean and environmentally friendly drive power supply. In today's application scenarios, it is widely used in pure electric vehicles, electric trains, electric vehicles and golf carts. In recent years, with the rise of the new energy vehicle sales market, the safety and reliability of power lithium batteries has become a topic of concern and discussion. The reason is not only that the power lithium battery is a key component of the power drive system software, but also that the power lithium battery production process itself has high reliability and reliability requirements. Taking automobile lithium batteries as an example, what role can low-temperature plasma cleaning machines play in the manufacturing process of power lithium batteries? What assistance can be provided for them?

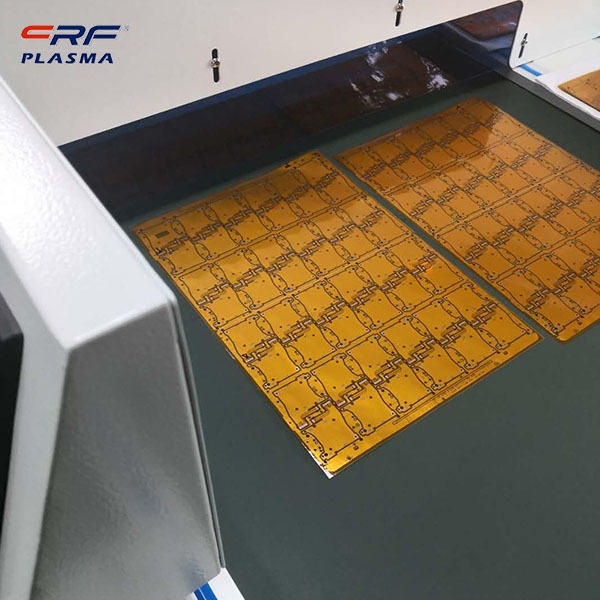

In the production process of automobile power lithium battery, the surface treatment of low-temperature plasma cleaning machine is generally carried out from three levels, that is, to improve the lubrication performance of the ceramic film before coating the positive and negative plates; to clean the connecting piece before lithium electric welding; and Improve the surface adhesion of insulating plates, end plates, PET plastic films and other metal composite materials and their insulating materials before external gluing of their lithium battery components.

1. Low-temperature plasma cleaning machine solves the problem of positive and negative two-stage coating before ceramic membrane plasma cleaning machine:

The positive and negative stages of the power lithium battery for automobiles are made according to the positive stage of the ceramic film and the battery cathode material. Compared with cleaning with ethanol and other aqueous solutions, plasma cleaning machine treatment will not damage the material itself, and can remove organic matter on the surface of the raw material, improve the lubricity of the film surface, and improve the uniformity, heat resistance and safety factor of the coating.

2. Plasma cleaning before welding:

The lithium tab actually refers to the part between the positive and negative stages of the metal material strip that correctly guides the rechargeable battery. It is a point contact type during battery charging and charging and discharging. Whether the surface of the connecting piece is clean or not has a great hazard to the reliability and performance of the electrical connection. Treatment with a plasma cleaner before electric welding can remove organic matter, particles and other residues on the surface of the weld, make the surface of the weld uneven, and improve the quality of steel lap welding.

3. Low-temperature plasma cleaning machine to process the raw rubber of lithium battery components:

The lithium battery assembly process is to connect several rechargeable battery modules in series into a series of parallel circuits to produce a lithium battery pack. In order to maintain the safety of the power supply circuit and the insulation layer, during this process, a rechargeable battery must be attached to the outside to improve the safety factor of the application. Prior to this, please use a plasma cleaning machine to clean the insulating plates, end plates, PET film and other parts. Plasma treatment can thoroughly clean the dirt surface, make the surface matte, and improve the adhesion of super glue or super glue.

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-12-10 20:44

- Views:

What role does the low-temperature plasma cleaning machine play in the production and manufacture of power lithium batteries:

Power lithium battery is a commonly used lithium battery powered by pneumatic tools. This is a clean and environmentally friendly drive power supply. In today's application scenarios, it is widely used in pure electric vehicles, electric trains, electric vehicles and golf carts. In recent years, with the rise of the new energy vehicle sales market, the safety and reliability of power lithium batteries has become a topic of concern and discussion. The reason is not only that the power lithium battery is a key component of the power drive system software, but also that the power lithium battery production process itself has high reliability and reliability requirements. Taking automobile lithium batteries as an example, what role can low-temperature plasma cleaning machines play in the manufacturing process of power lithium batteries? What assistance can be provided for them?

In the production process of automobile power lithium battery, the surface treatment of low-temperature plasma cleaning machine is generally carried out from three levels, that is, to improve the lubrication performance of the ceramic film before coating the positive and negative plates; to clean the connecting piece before lithium electric welding; and Improve the surface adhesion of insulating plates, end plates, PET plastic films and other metal composite materials and their insulating materials before external gluing of their lithium battery components.

1. Low-temperature plasma cleaning machine solves the problem of positive and negative two-stage coating before ceramic membrane plasma cleaning machine:

The positive and negative stages of the power lithium battery for automobiles are made according to the positive stage of the ceramic film and the battery cathode material. Compared with cleaning with ethanol and other aqueous solutions, plasma cleaning machine treatment will not damage the material itself, and can remove organic matter on the surface of the raw material, improve the lubricity of the film surface, and improve the uniformity, heat resistance and safety factor of the coating.

The positive and negative stages of the power lithium battery for automobiles are made according to the positive stage of the ceramic film and the battery cathode material. Compared with cleaning with ethanol and other aqueous solutions, plasma cleaning machine treatment will not damage the material itself, and can remove organic matter on the surface of the raw material, improve the lubricity of the film surface, and improve the uniformity, heat resistance and safety factor of the coating.

2. Plasma cleaning before welding:

The lithium tab actually refers to the part between the positive and negative stages of the metal material strip that correctly guides the rechargeable battery. It is a point contact type during battery charging and charging and discharging. Whether the surface of the connecting piece is clean or not has a great hazard to the reliability and performance of the electrical connection. Treatment with a plasma cleaner before electric welding can remove organic matter, particles and other residues on the surface of the weld, make the surface of the weld uneven, and improve the quality of steel lap welding.

3. Low-temperature plasma cleaning machine to process the raw rubber of lithium battery components:

The lithium battery assembly process is to connect several rechargeable battery modules in series into a series of parallel circuits to produce a lithium battery pack. In order to maintain the safety of the power supply circuit and the insulation layer, during this process, a rechargeable battery must be attached to the outside to improve the safety factor of the application. Prior to this, please use a plasma cleaning machine to clean the insulating plates, end plates, PET film and other parts. Plasma treatment can thoroughly clean the dirt surface, make the surface matte, and improve the adhesion of super glue or super glue.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen