Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Analyze the reasons why the plasma cleaning machine technology is so popular in the mobile phone LED industry:

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-08-25

- Views:

(Summary description)As a new method for surface modification of materials, plasma scrubbers have attracted much attention due to their advantages of low energy consumption, low pollution, short treatment time, and remarkable effects. Among many modification methods, low temperature plasma cleaning is a method that has developed rapidly in recent years. Compared with other methods, plasma cleaning has many advantages: First, plasma cleaning is a drying process, which is different from the elimination of wet chemical treatment, wastewater treatment, etc. Compared with other drying processes such as radiation, electron beam, corona, etc., which are indispensable drying processes, the uniqueness of plasma cleaning machines is that the effect on the material only occurs in the range of tens of thousands of angstroms on its surface, and at the same time The surface properties of a material can be changed without changing its bulk properties. Ultra-low temperature plasma scrubbers are widely used in mobile phones, automobiles, electronic circuit boards and other production fields. Due to the ionization, recombination, excitation and migration of atoms in the plasma, ultraviolet rays are generated, and the photon energy is also in the range of 2~4eV. Obviously, in plasma, the energy provided by particles and photons is very high. In fact, the main function of the plasma scrubber is not to clean, but to modify the surface of the material. By treating the surface of the material, the bonding ability of the material can be improved, and the problems of bonding, painting, printing and dyeing can be solved. The actual cleaning is to use ultrasonic washing and drying. The plasmaization process is usually followed by ultrasonic cleaning, where the surface of the material is ultrasonically cleaned, then modified by plasma surface treatment, and then bonded or coated. There are many industries in which plasma cleaning machines are used, and customers often take all kinds of wonderful samples to deal with, such as various small toy accessories, cloth

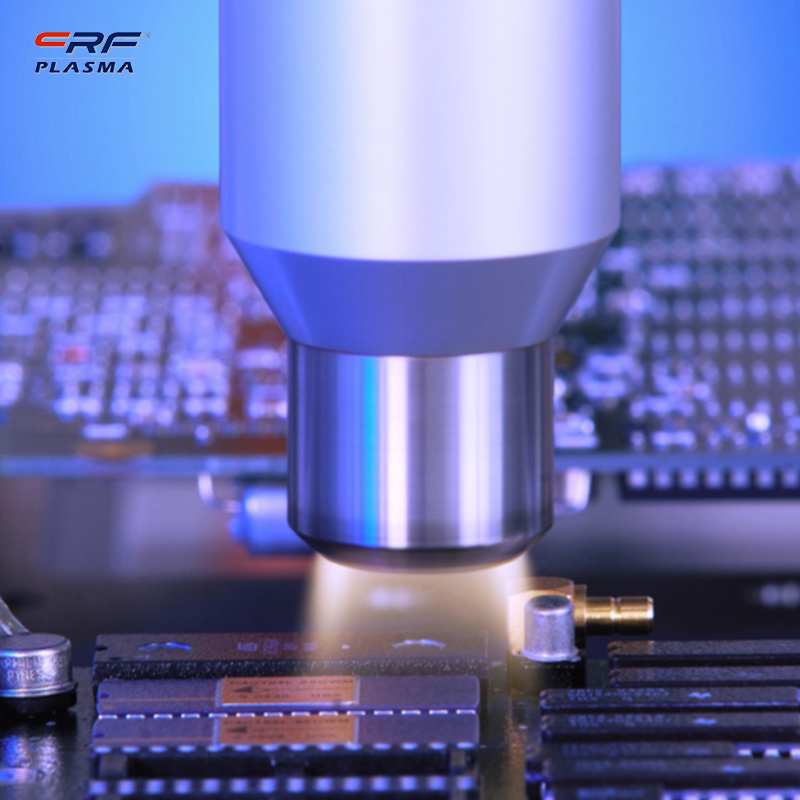

Analyze the reasons why the plasma cleaning machine technology is so popular in the mobile phone LED industry:

(Summary description)As a new method for surface modification of materials, plasma scrubbers have attracted much attention due to their advantages of low energy consumption, low pollution, short treatment time, and remarkable effects. Among many modification methods, low temperature plasma cleaning is a method that has developed rapidly in recent years. Compared with other methods, plasma cleaning has many advantages: First, plasma cleaning is a drying process, which is different from the elimination of wet chemical treatment, wastewater treatment, etc. Compared with other drying processes such as radiation, electron beam, corona, etc., which are indispensable drying processes, the uniqueness of plasma cleaning machines is that the effect on the material only occurs in the range of tens of thousands of angstroms on its surface, and at the same time The surface properties of a material can be changed without changing its bulk properties.

Ultra-low temperature plasma scrubbers are widely used in mobile phones, automobiles, electronic circuit boards and other production fields. Due to the ionization, recombination, excitation and migration of atoms in the plasma, ultraviolet rays are generated, and the photon energy is also in the range of 2~4eV. Obviously, in plasma, the energy provided by particles and photons is very high.

In fact, the main function of the plasma scrubber is not to clean, but to modify the surface of the material. By treating the surface of the material, the bonding ability of the material can be improved, and the problems of bonding, painting, printing and dyeing can be solved. The actual cleaning is to use ultrasonic washing and drying. The plasmaization process is usually followed by ultrasonic cleaning, where the surface of the material is ultrasonically cleaned, then modified by plasma surface treatment, and then bonded or coated.

There are many industries in which plasma cleaning machines are used, and customers often take all kinds of wonderful samples to deal with, such as various small toy accessories, cloth

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-08-25 15:46

- Views:

As a new method for surface modification of materials, plasma scrubbers have attracted much attention due to their advantages of low energy consumption, low pollution, short treatment time, and remarkable effects. Among many modification methods, low temperature plasma cleaning is a method that has developed rapidly in recent years. Compared with other methods, plasma cleaning has many advantages: First, plasma cleaning is a drying process, which is different from the elimination of wet chemical treatment, wastewater treatment, etc. Compared with other drying processes such as radiation, electron beam, corona, etc., which are indispensable drying processes, the uniqueness of plasma cleaning machines is that the effect on the material only occurs in the range of tens of thousands of angstroms on its surface, and at the same time The surface properties of a material can be changed without changing its bulk properties.

Ultra-low temperature plasma scrubbers are widely used in mobile phones, automobiles, electronic circuit boards and other production fields. Due to the ionization, recombination, excitation and migration of atoms in the plasma, ultraviolet rays are generated, and the photon energy is also in the range of 2~4eV. Obviously, in plasma, the energy provided by particles and photons is very high.

Ultra-low temperature plasma scrubbers are widely used in mobile phones, automobiles, electronic circuit boards and other production fields. Due to the ionization, recombination, excitation and migration of atoms in the plasma, ultraviolet rays are generated, and the photon energy is also in the range of 2~4eV. Obviously, in plasma, the energy provided by particles and photons is very high.

In fact, the main function of the plasma scrubber is not to clean, but to modify the surface of the material. By treating the surface of the material, the bonding ability of the material can be improved, and the problems of bonding, painting, printing and dyeing can be solved. The actual cleaning is to use ultrasonic washing and drying. The plasmaization process is usually followed by ultrasonic cleaning, where the surface of the material is ultrasonically cleaned, then modified by plasma surface treatment, and then bonded or coated.

There are many industries in which plasma cleaning machines are used, and customers often take all kinds of wonderful samples to deal with, such as various small toy accessories, cloth

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen