Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

How is the use of plasma cleaners in the electronic screen industry?

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-07-16

- Views:

(Summary description)How is the use of plasma cleaners in the electronic screen industry? Modern touch screens, LCD monitors and TV screens place high demands on the production process, because plastic parts must be treated with highly transparent scratch-resistant and anti-static coatings before bonding and assembly. Removing the impurities on the surface of the mobile phone screen and roughening the surface is conducive to improving the adhesion of the mobile phone screen coating and making it stick more firmly. Our conventional sandpaper polishing is obviously not suitable for use on the mobile phone screen, because it will Scratching the screen of the mobile phone will affect the use. Is there a way to remove the dirt on the surface of the screen and improve the roughness of the surface without affecting its aesthetics? The plasma treatment process of the plasma cleaning machine can be very solve this problem well. First of all, the plasma generated by the plasma surface cleaning machine contains electrons, ions and active free radicals. These particles are relatively easy to react with organic pollutants on the surface of the material to generate volatile and harmless gases, such as CO2 and water vapor. The whole reaction The process time is short, the efficiency is high, and the treatment effect is good. Secondly, when the plasma-treated mobile phone screen is being coated or sprayed, the active components in the plasma will quickly form chemical bonds with the material and the sprayed material. This bonding can greatly improve the strength of intermolecular bonding and make The film layer is difficult to loosen. The COG assembly process of the LCD is to mount the bare IC on the TO glass, and use the compression and deformation of the gold ball to make the pins on the ITO glass and the pins on the IC conduct. Due to the continuous development of fine line technology, it has developed to produce products with a pitch of 20um and a line of 10um. The production and assembly of these fine circuit electronic products have high requirements on the surface cleanliness of the TO glass, and the products are required to have good solderability, firm soldering, and no organic and inorganic substances remaining on the ITO glass to prevent the TO electrode terminals from contacting with each other. The continuity of the IC BUMP, therefore, the cleaning of the TO glass is very important. In the current ITO glass cleaning process, everyone is trying to use various cleaning agents (alcohol cleaning, cotton swab + lemonade cleaning) for cleaning, but due to the introduction of cleaning agents, it will lead to the introduction of cleaning agents. Therefore, exploring new cleaning methods has become the direction of efforts of various manufacturers. Through step-by-step tests, the principle of plasma cleaning is used to clean the surface of ITO glass, which is a more effective cleaning method. In the plasma cleaning of liquid crystal glass, the activated gas used is oxygen plasma, which can remove oily dirt and organic pollutant particles, because oxygen plasma can oxidize organic matter and form gas discharge. Its only problem is that it needs to add a static elimination device after removing the particles, and its cleaning process is as follows: Air blowing - oxygen plasma - static electricity removal The requirements of the electronics industry for a high degree of automation require the adoption of an online surface treatment process with high reliability, high production efficiency and treatment effect. The ultra-fine atmospheric plasma cleaning and plasma activation provided by the plasma process brings effective solutions to the electronics industry. Plasma treatment of the plastic viewing window section prior to antistatic and anti-scratch spraying on spray equipment. Due to the use of plasma cleaning technology, the surface energy of the material is increased, so the coating distribution is more uniform, the plasma cleaning machine not only creates an impeccable product appearance, but also greatly reduces the scrap rate in the production process.

How is the use of plasma cleaners in the electronic screen industry?

(Summary description)How is the use of plasma cleaners in the electronic screen industry?

Modern touch screens, LCD monitors and TV screens place high demands on the production process, because plastic parts must be treated with highly transparent scratch-resistant and anti-static coatings before bonding and assembly.

Removing the impurities on the surface of the mobile phone screen and roughening the surface is conducive to improving the adhesion of the mobile phone screen coating and making it stick more firmly. Our conventional sandpaper polishing is obviously not suitable for use on the mobile phone screen, because it will Scratching the screen of the mobile phone will affect the use. Is there a way to remove the dirt on the surface of the screen and improve the roughness of the surface without affecting its aesthetics? The plasma treatment process of the plasma cleaning machine can be very solve this problem well. First of all, the plasma generated by the plasma surface cleaning machine contains electrons, ions and active free radicals. These particles are relatively easy to react with organic pollutants on the surface of the material to generate volatile and harmless gases, such as CO2 and water vapor. The whole reaction The process time is short, the efficiency is high, and the treatment effect is good. Secondly, when the plasma-treated mobile phone screen is being coated or sprayed, the active components in the plasma will quickly form chemical bonds with the material and the sprayed material. This bonding can greatly improve the strength of intermolecular bonding and make The film layer is difficult to loosen.

The COG assembly process of the LCD is to mount the bare IC on the TO glass, and use the compression and deformation of the gold ball to make the pins on the ITO glass and the pins on the IC conduct. Due to the continuous development of fine line technology, it has developed to produce products with a pitch of 20um and a line of 10um. The production and assembly of these fine circuit electronic products have high requirements on the surface cleanliness of the TO glass, and the products are required to have good solderability, firm soldering, and no organic and inorganic substances remaining on the ITO glass to prevent the TO electrode terminals from contacting with each other. The continuity of the IC BUMP, therefore, the cleaning of the TO glass is very important. In the current ITO glass cleaning process, everyone is trying to use various cleaning agents (alcohol cleaning, cotton swab + lemonade cleaning) for cleaning, but due to the introduction of cleaning agents, it will lead to the introduction of cleaning agents. Therefore, exploring new cleaning methods has become the direction of efforts of various manufacturers. Through step-by-step tests, the principle of plasma cleaning is used to clean the surface of ITO glass, which is a more effective cleaning method.

In the plasma cleaning of liquid crystal glass, the activated gas used is oxygen plasma, which can remove oily dirt and organic pollutant particles, because oxygen plasma can oxidize organic matter and form gas discharge. Its only problem is that it needs to add a static elimination device after removing the particles, and its cleaning process is as follows:

Air blowing - oxygen plasma - static electricity removal

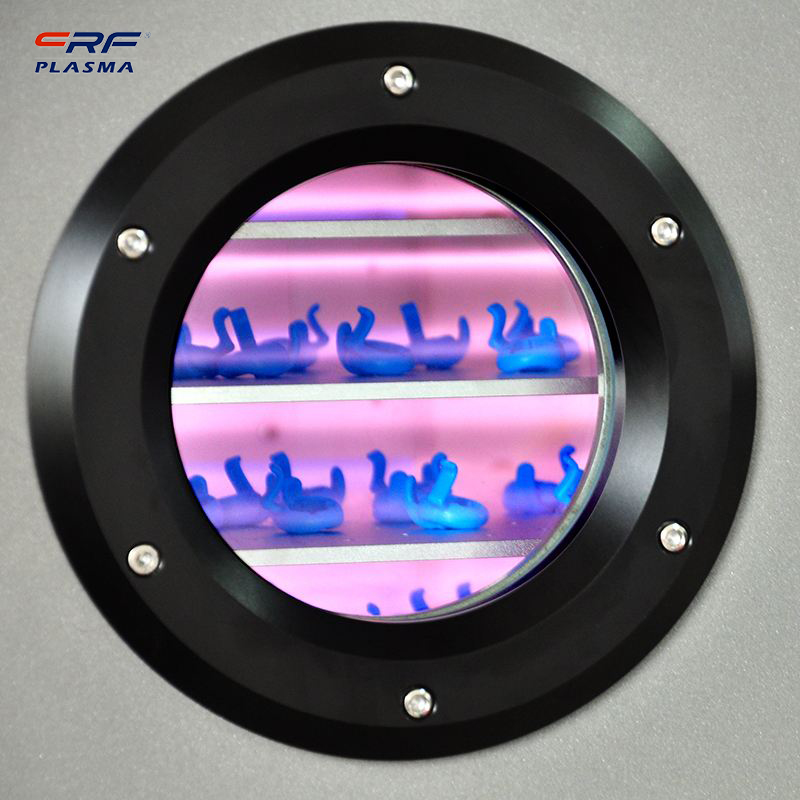

The requirements of the electronics industry for a high degree of automation require the adoption of an online surface treatment process with high reliability, high production efficiency and treatment effect. The ultra-fine atmospheric plasma cleaning and plasma activation provided by the plasma process brings effective solutions to the electronics industry. Plasma treatment of the plastic viewing window section prior to antistatic and anti-scratch spraying on spray equipment. Due to the use of plasma cleaning technology, the surface energy of the material is increased, so the coating distribution is more uniform, the plasma cleaning machine not only creates an impeccable product appearance, but also greatly reduces the scrap rate in the production process.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-07-16 14:12

- Views:

How is the use of plasma cleaners in the electronic screen industry?

Modern touch screens, LCD monitors and TV screens place high demands on the production process, because plastic parts must be treated with highly transparent scratch-resistant and anti-static coatings before bonding and assembly.

Removing the impurities on the surface of the mobile phone screen and roughening the surface is conducive to improving the adhesion of the mobile phone screen coating and making it stick more firmly. Our conventional sandpaper polishing is obviously not suitable for use on the mobile phone screen, because it will Scratching the screen of the mobile phone will affect the use. Is there a way to remove the dirt on the surface of the screen and improve the roughness of the surface without affecting its aesthetics? The plasma treatment process of the plasma cleaning machine can be very solve this problem well. First of all, the plasma generated by the plasma surface cleaning machine contains electrons, ions and active free radicals. These particles are relatively easy to react with organic pollutants on the surface of the material to generate volatile and harmless gases, such as CO2 and water vapor. The whole reaction The process time is short, the efficiency is high, and the treatment effect is good. Secondly, when the plasma-treated mobile phone screen is being coated or sprayed, the active components in the plasma will quickly form chemical bonds with the material and the sprayed material. This bonding can greatly improve the strength of intermolecular bonding and make The film layer is difficult to loosen.

Removing the impurities on the surface of the mobile phone screen and roughening the surface is conducive to improving the adhesion of the mobile phone screen coating and making it stick more firmly. Our conventional sandpaper polishing is obviously not suitable for use on the mobile phone screen, because it will Scratching the screen of the mobile phone will affect the use. Is there a way to remove the dirt on the surface of the screen and improve the roughness of the surface without affecting its aesthetics? The plasma treatment process of the plasma cleaning machine can be very solve this problem well. First of all, the plasma generated by the plasma surface cleaning machine contains electrons, ions and active free radicals. These particles are relatively easy to react with organic pollutants on the surface of the material to generate volatile and harmless gases, such as CO2 and water vapor. The whole reaction The process time is short, the efficiency is high, and the treatment effect is good. Secondly, when the plasma-treated mobile phone screen is being coated or sprayed, the active components in the plasma will quickly form chemical bonds with the material and the sprayed material. This bonding can greatly improve the strength of intermolecular bonding and make The film layer is difficult to loosen.

The COG assembly process of the LCD is to mount the bare IC on the TO glass, and use the compression and deformation of the gold ball to make the pins on the ITO glass and the pins on the IC conduct. Due to the continuous development of fine line technology, it has developed to produce products with a pitch of 20um and a line of 10um. The production and assembly of these fine circuit electronic products have high requirements on the surface cleanliness of the TO glass, and the products are required to have good solderability, firm soldering, and no organic and inorganic substances remaining on the ITO glass to prevent the TO electrode terminals from contacting with each other. The continuity of the IC BUMP, therefore, the cleaning of the TO glass is very important. In the current ITO glass cleaning process, everyone is trying to use various cleaning agents (alcohol cleaning, cotton swab + lemonade cleaning) for cleaning, but due to the introduction of cleaning agents, it will lead to the introduction of cleaning agents. Therefore, exploring new cleaning methods has become the direction of efforts of various manufacturers. Through step-by-step tests, the principle of plasma cleaning is used to clean the surface of ITO glass, which is a more effective cleaning method.

In the plasma cleaning of liquid crystal glass, the activated gas used is oxygen plasma, which can remove oily dirt and organic pollutant particles, because oxygen plasma can oxidize organic matter and form gas discharge. Its only problem is that it needs to add a static elimination device after removing the particles, and its cleaning process is as follows:

Air blowing - oxygen plasma - static electricity removal

The requirements of the electronics industry for a high degree of automation require the adoption of an online surface treatment process with high reliability, high production efficiency and treatment effect. The ultra-fine atmospheric plasma cleaning and plasma activation provided by the plasma process brings effective solutions to the electronics industry. Plasma treatment of the plastic viewing window section prior to antistatic and anti-scratch spraying on spray equipment. Due to the use of plasma cleaning technology, the surface energy of the material is increased, so the coating distribution is more uniform, the plasma cleaning machine not only creates an impeccable product appearance, but also greatly reduces the scrap rate in the production process.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen