Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

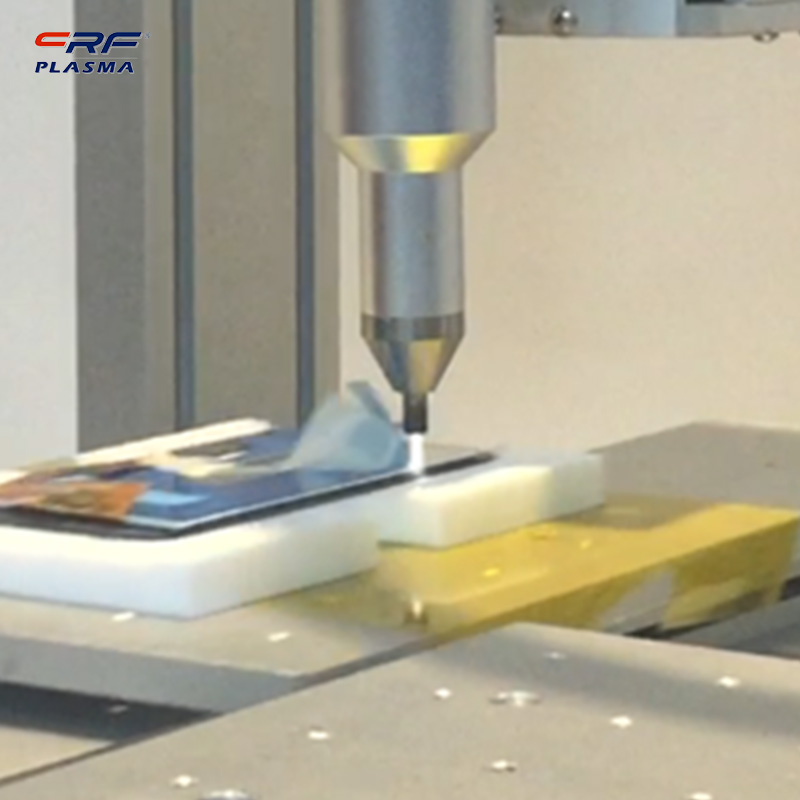

Circuit board plasma etching cleaning equipment to remove surface material polysilicon impurities and remove glue

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-03-29

- Views:

(Summary description)Circuit board plasma etching cleaning equipment to remove surface material polysilicon impurities and remove glue: With the continuous development of semiconductor process technology, wet etching technology has gradually limited its development due to its inherent limitations, and can no longer meet the processing requirements of VLSI micron or even nanowires. Plasma etching cleaning equipment Polycrystalline silicon wafer cleaning equipment Dry etching method has gradually been widely used in semiconductor processing due to its high ion density, uniform etching, high verticality of etched sidewalls, high surface finish, and ability to remove surface impurities. . Plasma surface treatment machine removes glue, and the gas for removing glue is oxygen. In the invention, the circuit board is placed in a vacuum reaction system, a small amount of oxygen is introduced, and a high frequency and high voltage are added, and a high frequency signal is generated by a high frequency signal generator, and a strong electromagnetic field is formed in the quartz tube to ionize oxygen. The mixed substances such as oxygen ions, oxygen atoms, oxygen molecules, and electrons form a glow column. Active atomic oxygen can rapidly oxidize the residual colloid into volatile gas, and make it volatilize and be taken away. With the development of modern semiconductor technology, the requirements for etching processing are getting higher and higher, and the plasma etching cleaning equipment for polysilicon wafers has also emerged as the times require. Product stability is one of the key factors to ensure the stability and repeatability of the product production process. CRF Chengfeng Zhizao plasma cleaning machine is a multi-functional plasma surface treatment equipment. By configuring different components, it has various functions such as coating (coating), corrosion, plasma chemical reaction and powder plasma treatment. After removing the residue from the circuit board, clean the circuit board. The circuit board plasma surface treatment machine has the advantages of simple operation, high glue removal efficiency, clean and smooth surface, no scratches, low cost and environmental protection. It has a good etching effect on polycrystalline silicon wafers by plasma cleaning machine/etching machine. By configuring the etching components, the utility model can make the plasma etching cleaning equipment made by CRF Chengfeng realize the etching function. The degumming process of the plasma surface treatment machine is an important link in the micro-fabrication. After the micro-nano processing such as electron beam exposure and ultraviolet exposure, the photoresist needs to be degummed or primed. Whether there is damage to the sample due to the cleanliness of the photoresist removal will directly affect the smooth implementation of the subsequent process. Plasma cleaning machine is a device that uses the characteristics of low temperature plasma to perform plasma surface treatment on treated materials. Generally, after plasma treatment, the material will have surface tension, wettability and hydrophilicity. When the dyne value changes, the dyne value will also change. There are many materials suitable for testing dyne pens, such as stainless steel, glass, plastic, ceramic lamps, etc. The dyne value is mainly reflected by the dyne pen, also known as surface tension detection pen, corona treatment pen and plastic film surface tension detection pen. Use 32, 34, 36, 38, 40, 42, 44, 46, 48, 50, 52, 54, 56, 58, 60 and other test pens with different tensions to test the surface tension of the sample to determine whether the surface tension of the sample is to the required value. Chengfeng Zhizao's plasma surface treatment machine adopts components with excellent performance, which can control process parameters, and its process monitoring and data acquisition software can achieve strict quality control. The technology has been successfully applied in power transistors, analog devices, sensors, optical devices, optoelectronics, electronic devices, MOEMS, biological devices, LEDs and other fields. Through plasma surface cleaning and activation treatment, the surface energy of conventional materials can be improved, which is reflected in the material's dyne value improvement test. The polymer plastic samples were treated by Chengfeng Zhizhi plasma cleaning machine, and the dyne values were compared before and after treatment. Before untreated, dyne scribed on the surface of the sample. After 40# scribed, it slowly shrank, and beads appeared, indicating that the dyne value was between 30 and 40; It can be evenly distributed, and there is no beading point, indicating that the dyne value of the sample surface is greater than 50. After being treated by a plasma cleaner, the surface tension of the material can be increased and the surface energy can be increased, which provides the possibility for subsequent processes and material applications. Using CR

Circuit board plasma etching cleaning equipment to remove surface material polysilicon impurities and remove glue

(Summary description)Circuit board plasma etching cleaning equipment to remove surface material polysilicon impurities and remove glue:

With the continuous development of semiconductor process technology, wet etching technology has gradually limited its development due to its inherent limitations, and can no longer meet the processing requirements of VLSI micron or even nanowires. Plasma etching cleaning equipment Polycrystalline silicon wafer cleaning equipment Dry etching method has gradually been widely used in semiconductor processing due to its high ion density, uniform etching, high verticality of etched sidewalls, high surface finish, and ability to remove surface impurities. . Plasma surface treatment machine removes glue, and the gas for removing glue is oxygen. In the invention, the circuit board is placed in a vacuum reaction system, a small amount of oxygen is introduced, and a high frequency and high voltage are added, and a high frequency signal is generated by a high frequency signal generator, and a strong electromagnetic field is formed in the quartz tube to ionize oxygen. The mixed substances such as oxygen ions, oxygen atoms, oxygen molecules, and electrons form a glow column. Active atomic oxygen can rapidly oxidize the residual colloid into volatile gas, and make it volatilize and be taken away.

With the development of modern semiconductor technology, the requirements for etching processing are getting higher and higher, and the plasma etching cleaning equipment for polysilicon wafers has also emerged as the times require. Product stability is one of the key factors to ensure the stability and repeatability of the product production process. CRF Chengfeng Zhizao plasma cleaning machine is a multi-functional plasma surface treatment equipment. By configuring different components, it has various functions such as coating (coating), corrosion, plasma chemical reaction and powder plasma treatment. After removing the residue from the circuit board, clean the circuit board. The circuit board plasma surface treatment machine has the advantages of simple operation, high glue removal efficiency, clean and smooth surface, no scratches, low cost and environmental protection.

It has a good etching effect on polycrystalline silicon wafers by plasma cleaning machine/etching machine. By configuring the etching components, the utility model can make the plasma etching cleaning equipment made by CRF Chengfeng realize the etching function. The degumming process of the plasma surface treatment machine is an important link in the micro-fabrication. After the micro-nano processing such as electron beam exposure and ultraviolet exposure, the photoresist needs to be degummed or primed. Whether there is damage to the sample due to the cleanliness of the photoresist removal will directly affect the smooth implementation of the subsequent process.

Plasma cleaning machine is a device that uses the characteristics of low temperature plasma to perform plasma surface treatment on treated materials. Generally, after plasma treatment, the material will have surface tension, wettability and hydrophilicity. When the dyne value changes, the dyne value will also change. There are many materials suitable for testing dyne pens, such as stainless steel, glass, plastic, ceramic lamps, etc.

The dyne value is mainly reflected by the dyne pen, also known as surface tension detection pen, corona treatment pen and plastic film surface tension detection pen. Use 32, 34, 36, 38, 40, 42, 44, 46, 48, 50, 52, 54, 56, 58, 60 and other test pens with different tensions to test the surface tension of the sample to determine whether the surface tension of the sample is to the required value. Chengfeng Zhizao's plasma surface treatment machine adopts components with excellent performance, which can control process parameters, and its process monitoring and data acquisition software can achieve strict quality control. The technology has been successfully applied in power transistors, analog devices, sensors, optical devices, optoelectronics, electronic devices, MOEMS, biological devices, LEDs and other fields.

Through plasma surface cleaning and activation treatment, the surface energy of conventional materials can be improved, which is reflected in the material's dyne value improvement test. The polymer plastic samples were treated by Chengfeng Zhizhi plasma cleaning machine, and the dyne values were compared before and after treatment. Before untreated, dyne scribed on the surface of the sample. After 40# scribed, it slowly shrank, and beads appeared, indicating that the dyne value was between 30 and 40; It can be evenly distributed, and there is no beading point, indicating that the dyne value of the sample surface is greater than 50. After being treated by a plasma cleaner, the surface tension of the material can be increased and the surface energy can be increased, which provides the possibility for subsequent processes and material applications.

Using CR

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2022-03-29 16:44

- Views:

Circuit board plasma etching cleaning equipment to remove surface material polysilicon impurities and remove glue:

With the continuous development of semiconductor process technology, wet etching technology has gradually limited its development due to its inherent limitations, and can no longer meet the processing requirements of VLSI micron or even nanowires. Plasma etching cleaning equipment Polycrystalline silicon wafer cleaning equipment Dry etching method has gradually been widely used in semiconductor processing due to its high ion density, uniform etching, high verticality of etched sidewalls, high surface finish, and ability to remove surface impurities. . Plasma surface treatment machine removes glue, and the gas for removing glue is oxygen. In the invention, the circuit board is placed in a vacuum reaction system, a small amount of oxygen is introduced, and a high frequency and high voltage are added, and a high frequency signal is generated by a high frequency signal generator, and a strong electromagnetic field is formed in the quartz tube to ionize oxygen. The mixed substances such as oxygen ions, oxygen atoms, oxygen molecules, and electrons form a glow column. Active atomic oxygen can rapidly oxidize the residual colloid into volatile gas, and make it volatilize and be taken away.

With the development of modern semiconductor technology, the requirements for etching processing are getting higher and higher, and the plasma etching cleaning equipment for polysilicon wafers has also emerged as the times require. Product stability is one of the key factors to ensure the stability and repeatability of the product production process. CRF Chengfeng Zhizao plasma cleaning machine is a multi-functional plasma surface treatment equipment. By configuring different components, it has various functions such as coating (coating), corrosion, plasma chemical reaction and powder plasma treatment. After removing the residue from the circuit board, clean the circuit board. The circuit board plasma surface treatment machine has the advantages of simple operation, high glue removal efficiency, clean and smooth surface, no scratches, low cost and environmental protection.

It has a good etching effect on polycrystalline silicon wafers by plasma cleaning machine/etching machine. By configuring the etching components, the utility model can make the plasma etching cleaning equipment made by CRF Chengfeng realize the etching function. The degumming process of the plasma surface treatment machine is an important link in the micro-fabrication. After the micro-nano processing such as electron beam exposure and ultraviolet exposure, the photoresist needs to be degummed or primed. Whether there is damage to the sample due to the cleanliness of the photoresist removal will directly affect the smooth implementation of the subsequent process.

It has a good etching effect on polycrystalline silicon wafers by plasma cleaning machine/etching machine. By configuring the etching components, the utility model can make the plasma etching cleaning equipment made by CRF Chengfeng realize the etching function. The degumming process of the plasma surface treatment machine is an important link in the micro-fabrication. After the micro-nano processing such as electron beam exposure and ultraviolet exposure, the photoresist needs to be degummed or primed. Whether there is damage to the sample due to the cleanliness of the photoresist removal will directly affect the smooth implementation of the subsequent process.

Plasma cleaning machine is a device that uses the characteristics of low temperature plasma to perform plasma surface treatment on treated materials. Generally, after plasma treatment, the material will have surface tension, wettability and hydrophilicity. When the dyne value changes, the dyne value will also change. There are many materials suitable for testing dyne pens, such as stainless steel, glass, plastic, ceramic lamps, etc.

The dyne value is mainly reflected by the dyne pen, also known as surface tension detection pen, corona treatment pen and plastic film surface tension detection pen. Use 32, 34, 36, 38, 40, 42, 44, 46, 48, 50, 52, 54, 56, 58, 60 and other test pens with different tensions to test the surface tension of the sample to determine whether the surface tension of the sample is to the required value. Chengfeng Zhizao's plasma surface treatment machine adopts components with excellent performance, which can control process parameters, and its process monitoring and data acquisition software can achieve strict quality control. The technology has been successfully applied in power transistors, analog devices, sensors, optical devices, optoelectronics, electronic devices, MOEMS, biological devices, LEDs and other fields.

Through plasma surface cleaning and activation treatment, the surface energy of conventional materials can be improved, which is reflected in the material's dyne value improvement test. The polymer plastic samples were treated by Chengfeng Zhizhi plasma cleaning machine, and the dyne values were compared before and after treatment. Before untreated, dyne scribed on the surface of the sample. After 40# scribed, it slowly shrank, and beads appeared, indicating that the dyne value was between 30 and 40; It can be evenly distributed, and there is no beading point, indicating that the dyne value of the sample surface is greater than 50. After being treated by a plasma cleaner, the surface tension of the material can be increased and the surface energy can be increased, which provides the possibility for subsequent processes and material applications.

Using CRF Chengfeng Zhizhi Plasma Glue Remover to treat the dirt on the surface of the PCB board, the effect is very obvious. The utility model has the characteristics of simple process, reliability, high efficiency, and no acid waste water and other residues after treatment.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen