Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

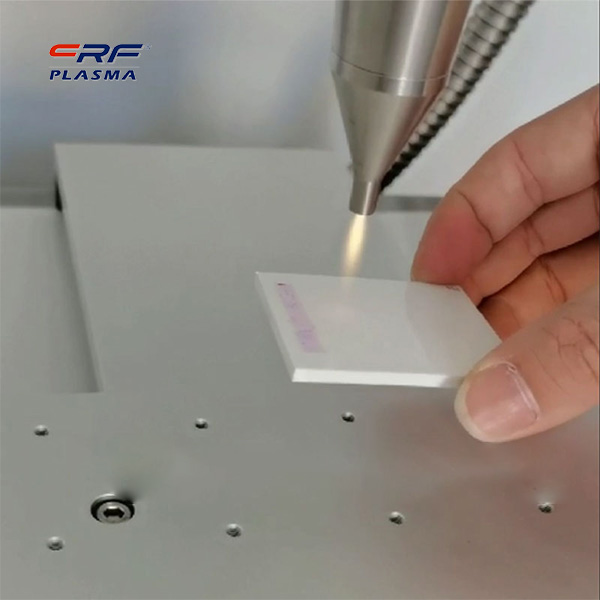

Atmospheric plasma cleaning equipment low temperature plasma coating modified PVDF sulfonic acid membrane

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-14

- Views:

(Summary description)Atmospheric plasma cleaning equipment low temperature plasma coating modified PVDF sulfonic acid membrane: In recent years, membrane technology has the advantages of high energy efficiency, high separation capacity, high selectivity, and relatively low cost. It is competitive in various industries and has been widely developed. The current application areas include acid recovery, salt manufacturing, food desalination, and process Wastewater desalination, organic synthesis, etc. Polyvinylidene fluoride (PVDF) is a copolymer of fluorine-containing vinyl monomers. Its high molecular weight can reach millions. Compared with other commercial polymer membrane materials, it has excellent weather resistance, thermal stability, chemical stability and Excellent mechanical properties. PVDF forms double bonds through alkalization to graft styrene monomer, and then sulfonates to introduce active groups. The cation exchange membrane prepared by this process has high ion exchange capacity and good mechanical strength. However, commercial products based on polystyrene are not Homogeneous membranes and alloy membranes often need to add mesh to increase the overall strength of the membrane. In terms of oxidation resistance, the PVDFgPSSA homogeneous membrane is better than the first two commercial membranes, which fully reflects the excellent characteristics of PVDF as a polymer membrane skeleton, but the selective permeability of the prepared membrane often cannot meet the requirements of industrial use. Therefore, it is necessary to modify the membrane with atmospheric plasma cleaning equipment. Common methods for PVDF separation membrane modification include plasma modification, blending modification, chemical modification, etc. of atmospheric plasma cleaning equipment. Compared with the blending modification, although the modification conditions are easy to achieve, the inorganic nanomaterials are easy to agglomerate in the film casting solution, resulting in uneven distribution in the PVDF membrane and reducing the effect of inorganic material modification. In contrast, plasma modification has wide applicability. The modification can uniformly act on the entire PVDF film surface. The plasma modification depth is tens of nanometers, which will not cause major damage to the internal structure of the film. The plasma of the atmospheric plasma cleaning equipment can cause a series of physical and chemical reactions such as cross-linking and initiating grafting on the surface of the PVDF membrane. The surface of the membrane becomes denser and smoother after coating and graft modification, which can effectively improve the barrier of the PVDF sulfonic acid membrane to chloride ions. However, the surface of the film is etched due to excessive irradiation, and the selective permeability of the film is reduced.

Atmospheric plasma cleaning equipment low temperature plasma coating modified PVDF sulfonic acid membrane

(Summary description)Atmospheric plasma cleaning equipment low temperature plasma coating modified PVDF sulfonic acid membrane:

In recent years, membrane technology has the advantages of high energy efficiency, high separation capacity, high selectivity, and relatively low cost. It is competitive in various industries and has been widely developed. The current application areas include acid recovery, salt manufacturing, food desalination, and process Wastewater desalination, organic synthesis, etc.

Polyvinylidene fluoride (PVDF) is a copolymer of fluorine-containing vinyl monomers. Its high molecular weight can reach millions. Compared with other commercial polymer membrane materials, it has excellent weather resistance, thermal stability, chemical stability and Excellent mechanical properties.

PVDF forms double bonds through alkalization to graft styrene monomer, and then sulfonates to introduce active groups. The cation exchange membrane prepared by this process has high ion exchange capacity and good mechanical strength. However, commercial products based on polystyrene are not Homogeneous membranes and alloy membranes often need to add mesh to increase the overall strength of the membrane.

In terms of oxidation resistance, the PVDFgPSSA homogeneous membrane is better than the first two commercial membranes, which fully reflects the excellent characteristics of PVDF as a polymer membrane skeleton, but the selective permeability of the prepared membrane often cannot meet the requirements of industrial use. Therefore, it is necessary to modify the membrane with atmospheric plasma cleaning equipment.

Common methods for PVDF separation membrane modification include plasma modification, blending modification, chemical modification, etc. of atmospheric plasma cleaning equipment. Compared with the blending modification, although the modification conditions are easy to achieve, the inorganic nanomaterials are easy to agglomerate in the film casting solution, resulting in uneven distribution in the PVDF membrane and reducing the effect of inorganic material modification.

In contrast, plasma modification has wide applicability. The modification can uniformly act on the entire PVDF film surface. The plasma modification depth is tens of nanometers, which will not cause major damage to the internal structure of the film.

The plasma of the atmospheric plasma cleaning equipment can cause a series of physical and chemical reactions such as cross-linking and initiating grafting on the surface of the PVDF membrane. The surface of the membrane becomes denser and smoother after coating and graft modification, which can effectively improve the barrier of the PVDF sulfonic acid membrane to chloride ions. However, the surface of the film is etched due to excessive irradiation, and the selective permeability of the film is reduced.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-14 17:23

- Views:

Atmospheric plasma cleaning equipment low temperature plasma coating modified PVDF sulfonic acid membrane:

In recent years, membrane technology has the advantages of high energy efficiency, high separation capacity, high selectivity, and relatively low cost. It is competitive in various industries and has been widely developed. The current application areas include acid recovery, salt manufacturing, food desalination, and process Wastewater desalination, organic synthesis, etc.

Polyvinylidene fluoride (PVDF) is a copolymer of fluorine-containing vinyl monomers. Its high molecular weight can reach millions. Compared with other commercial polymer membrane materials, it has excellent weather resistance, thermal stability, chemical stability and Excellent mechanical properties.

Polyvinylidene fluoride (PVDF) is a copolymer of fluorine-containing vinyl monomers. Its high molecular weight can reach millions. Compared with other commercial polymer membrane materials, it has excellent weather resistance, thermal stability, chemical stability and Excellent mechanical properties.

PVDF forms double bonds through alkalization to graft styrene monomer, and then sulfonates to introduce active groups. The cation exchange membrane prepared by this process has high ion exchange capacity and good mechanical strength. However, commercial products based on polystyrene are not Homogeneous membranes and alloy membranes often need to add mesh to increase the overall strength of the membrane.

In terms of oxidation resistance, the PVDFgPSSA homogeneous membrane is better than the first two commercial membranes, which fully reflects the excellent characteristics of PVDF as a polymer membrane skeleton, but the selective permeability of the prepared membrane often cannot meet the requirements of industrial use. Therefore, it is necessary to modify the membrane with atmospheric plasma cleaning equipment.

Common methods for PVDF separation membrane modification include plasma modification, blending modification, chemical modification, etc. of atmospheric plasma cleaning equipment. Compared with the blending modification, although the modification conditions are easy to achieve, the inorganic nanomaterials are easy to agglomerate in the film casting solution, resulting in uneven distribution in the PVDF membrane and reducing the effect of inorganic material modification.

In contrast, plasma modification has wide applicability. The modification can uniformly act on the entire PVDF film surface. The plasma modification depth is tens of nanometers, which will not cause major damage to the internal structure of the film.

The plasma of the atmospheric plasma cleaning equipment can cause a series of physical and chemical reactions such as cross-linking and initiating grafting on the surface of the PVDF membrane. The surface of the membrane becomes denser and smoother after coating and graft modification, which can effectively improve the barrier of the PVDF sulfonic acid membrane to chloride ions. However, the surface of the film is etched due to excessive irradiation, and the selective permeability of the film is reduced.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen