Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

The edge effect of low-temperature plasma surface treatment DC glow plasma

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-11

- Views:

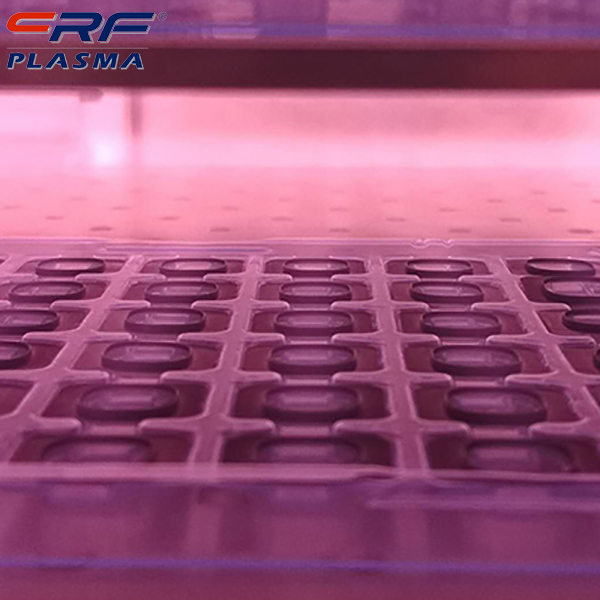

(Summary description)The edge effect of low-temperature plasma surface treatment DC glow plasma: Low-temperature low-temperature plasma surface treatment Plasma is widely used in material treatment. The existing treatment technologies include plasma cleaning, glow nitriding, magnetron sputtering, multi-arc ion plating, plasma etching, ion implantation, etc., related Discharge forms are divided into direct current glow discharge, radio frequency plasma discharge, high voltage pulse direct current discharge and so on. However, due to the different shapes of the processed workpiece materials, many of them have obvious edges and corners, so "edge effects" appear, which have varying degrees of impact on material properties, especially in terms of uniformity, thickness, and mechanical properties. Glow nitriding is also called ion nitriding. It uses glow discharge to generate plasma. Under the action of low-temperature plasma surface treatment plasma and strong electric field, high-speed nitrogen and hydrogen positive ions bombard the surface of the workpiece, and nitrogen will penetrate the surface of the workpiece. . Nitrogen infiltrated into the material can form helium compounds, which have high hardness, thermal stability, and dispersion, so the mechanical properties of the material will be greatly improved. It is a high-performance nitriding method with short nitriding cycle, low brittleness of the nitriding layer, controllable thickness and organization of the nitriding layer, and has the effect of purifying the surface. The central problem of the low-temperature plasma process is that there is a sheath layer between the plasma and the substrate, and the ions are accelerated through the sheath layer, thereby causing bombardment, sputtering, and injection to the material to achieve modification. Nitriding is a direct current glow discharge, which is set in a vacuum chamber with a certain size to perform a low-pressure, non-magnetic direct current glow discharge and generate plasma. Since the entire plasma is in an electrically neutral state, the potential at the plasma boundary is the same, and the workpiece to be processed is regarded as an equipotential body, and the potential difference between the two is the sheath potential difference. If the corners of the workpiece have no functional or shape requirements, the corners can be cambered. Since there is no abnormal electric field distribution, the sheath voltage and thickness are constant, and the ion density is the same, so the hardness of the nitrided layer is uniform. In the range from the edge of the DC glow of the low-temperature plasma surface treatment, the closer to the corners, the greater the electric field intensity and ion density, and the smaller the sheath thickness. After the corner arc surface treatment, because there is no corner, there is no edge effect; the main plasma density can be reduced, the edge effect is suppressed, and the nitriding effect is better.

The edge effect of low-temperature plasma surface treatment DC glow plasma

(Summary description)The edge effect of low-temperature plasma surface treatment DC glow plasma:

Low-temperature low-temperature plasma surface treatment Plasma is widely used in material treatment. The existing treatment technologies include plasma cleaning, glow nitriding, magnetron sputtering, multi-arc ion plating, plasma etching, ion implantation, etc., related Discharge forms are divided into direct current glow discharge, radio frequency plasma discharge, high voltage pulse direct current discharge and so on.

However, due to the different shapes of the processed workpiece materials, many of them have obvious edges and corners, so "edge effects" appear, which have varying degrees of impact on material properties, especially in terms of uniformity, thickness, and mechanical properties. Glow nitriding is also called ion nitriding. It uses glow discharge to generate plasma. Under the action of low-temperature plasma surface treatment plasma and strong electric field, high-speed nitrogen and hydrogen positive ions bombard the surface of the workpiece, and nitrogen will penetrate the surface of the workpiece. . Nitrogen infiltrated into the material can form helium compounds, which have high hardness, thermal stability, and dispersion, so the mechanical properties of the material will be greatly improved.

It is a high-performance nitriding method with short nitriding cycle, low brittleness of the nitriding layer, controllable thickness and organization of the nitriding layer, and has the effect of purifying the surface. The central problem of the low-temperature plasma process is that there is a sheath layer between the plasma and the substrate, and the ions are accelerated through the sheath layer, thereby causing bombardment, sputtering, and injection to the material to achieve modification.

Nitriding is a direct current glow discharge, which is set in a vacuum chamber with a certain size to perform a low-pressure, non-magnetic direct current glow discharge and generate plasma. Since the entire plasma is in an electrically neutral state, the potential at the plasma boundary is the same, and the workpiece to be processed is regarded as an equipotential body, and the potential difference between the two is the sheath potential difference.

If the corners of the workpiece have no functional or shape requirements, the corners can be cambered. Since there is no abnormal electric field distribution, the sheath voltage and thickness are constant, and the ion density is the same, so the hardness of the nitrided layer is uniform. In the range from the edge of the DC glow of the low-temperature plasma surface treatment, the closer to the corners, the greater the electric field intensity and ion density, and the smaller the sheath thickness. After the corner arc surface treatment, because there is no corner, there is no edge effect; the main plasma density can be reduced, the edge effect is suppressed, and the nitriding effect is better.

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-11 20:46

- Views:

The edge effect of low-temperature plasma surface treatment DC glow plasma:

Low-temperature low-temperature plasma surface treatment Plasma is widely used in material treatment. The existing treatment technologies include plasma cleaning, glow nitriding, magnetron sputtering, multi-arc ion plating, plasma etching, ion implantation, etc., related Discharge forms are divided into direct current glow discharge, radio frequency plasma discharge, high voltage pulse direct current discharge and so on.

However, due to the different shapes of the processed workpiece materials, many of them have obvious edges and corners, so "edge effects" appear, which have varying degrees of impact on material properties, especially in terms of uniformity, thickness, and mechanical properties. Glow nitriding is also called ion nitriding. It uses glow discharge to generate plasma. Under the action of low-temperature plasma surface treatment plasma and strong electric field, high-speed nitrogen and hydrogen positive ions bombard the surface of the workpiece, and nitrogen will penetrate the surface of the workpiece. . Nitrogen infiltrated into the material can form helium compounds, which have high hardness, thermal stability, and dispersion, so the mechanical properties of the material will be greatly improved.

It is a high-performance nitriding method with short nitriding cycle, low brittleness of the nitriding layer, controllable thickness and organization of the nitriding layer, and has the effect of purifying the surface. The central problem of the low-temperature plasma process is that there is a sheath layer between the plasma and the substrate, and the ions are accelerated through the sheath layer, thereby causing bombardment, sputtering, and injection to the material to achieve modification.

Nitriding is a direct current glow discharge, which is set in a vacuum chamber with a certain size to perform a low-pressure, non-magnetic direct current glow discharge and generate plasma. Since the entire plasma is in an electrically neutral state, the potential at the plasma boundary is the same, and the workpiece to be processed is regarded as an equipotential body, and the potential difference between the two is the sheath potential difference.

Nitriding is a direct current glow discharge, which is set in a vacuum chamber with a certain size to perform a low-pressure, non-magnetic direct current glow discharge and generate plasma. Since the entire plasma is in an electrically neutral state, the potential at the plasma boundary is the same, and the workpiece to be processed is regarded as an equipotential body, and the potential difference between the two is the sheath potential difference.

If the corners of the workpiece have no functional or shape requirements, the corners can be cambered. Since there is no abnormal electric field distribution, the sheath voltage and thickness are constant, and the ion density is the same, so the hardness of the nitrided layer is uniform. In the range from the edge of the DC glow of the low-temperature plasma surface treatment, the closer to the corners, the greater the electric field intensity and ion density, and the smaller the sheath thickness. After the corner arc surface treatment, because there is no corner, there is no edge effect; the main plasma density can be reduced, the edge effect is suppressed, and the nitriding effect is better.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen