Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

The effect of carbon nanotube filler on the failure of varnish coating by surface treatment of atmospheric plasma machin

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-03

- Views:

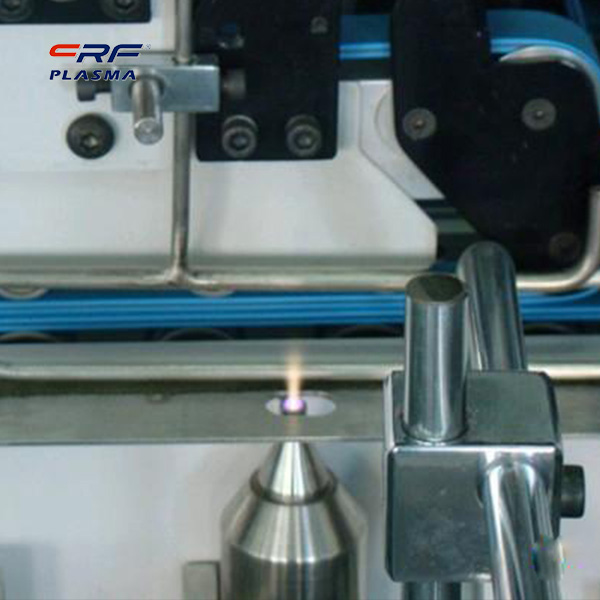

(Summary description)The effect of carbon nanotube filler on the failure of varnish coating by surface treatment of atmospheric plasma machine: In the natural environment, materials will undergo chemical or electrochemical effects due to environmental influences, which will cause corrosion failure, lose their original mechanical properties and structural effects, and cause potential safety hazards and economic losses. Corrosion in the atmospheric environment, soil environment and marine environment is highlighted by marine corrosion. In terms of marine corrosion protection, paint protection occupies a high proportion, which makes the research of coatings in seawater environments a hot spot. Through the modification of the coating itself and the coating attachment matrix, the effect of improving the service life of the coating and improving the quality of the protection of the coating is achieved. Compared with the traditional modification technology, the plasma treatment of atmospheric plasma machine has the characteristics of environmental protection, no pollution, no damage to the overall nature of the body surface, wide application range, and safety. In terms of surface modification of the substrate, plasma treatment is applied to the substrate. After plasma treatment, functional groups for connectivity are added to the surface of the substrate, such as hydroxyl (-OH), carbonyl (-CO) and other functional groups. These functional groups can react with the unsaturated double bond (-C=C-), carboxyl (R-OOH), hydroxyl R-OH, aliphatic (R-OOR) and other functional groups in the alkyd resin to form chemical bonds to improve the coating Bonding force with the substrate. In addition, plasma treatment with atmospheric plasma machine can also increase the surface roughness and increase the bonding force from the physical aspect. Electrochemical impedance (EIS) and scanning Kelvin probe test (SKP) results have proved that plasma treatment can enhance the protective performance of the coating and delay the failure of the coating. In order to improve the water seepage and corrosion resistance of the coating itself, nano-scale multi-walled carbon nanotubes are added to the varnish to act as pigments and fillers. The addition of carbon nanotubes increases the compactness of the film-forming coating, fills the channels for water molecules to penetrate, significantly prolongs the time it takes for water to penetrate from the coating surface to the substrate surface, delays the coating failure, and increases the service life of the coating. Analyze from the perspective of molecular mechanics. By simulating the plasma treatment on the surface of the iron substrate, the changes in the adsorption energy of the alkyd resin on the surface of the untreated iron substrate and the surface of the iron substrate treated by an atmospheric plasma machine are compared. The results prove that plasma treatment on the surface of the iron substrate can promote the adsorption of alkyd resin on the surface of the substrate. The effect of plasma surface treatment and carbon nanotube filler on the failure of the varnish coating can improve the protective effect of the coating and increase the life of the coating.

The effect of carbon nanotube filler on the failure of varnish coating by surface treatment of atmospheric plasma machin

(Summary description)The effect of carbon nanotube filler on the failure of varnish coating by surface treatment of atmospheric plasma machine:

In the natural environment, materials will undergo chemical or electrochemical effects due to environmental influences, which will cause corrosion failure, lose their original mechanical properties and structural effects, and cause potential safety hazards and economic losses.

Corrosion in the atmospheric environment, soil environment and marine environment is highlighted by marine corrosion. In terms of marine corrosion protection, paint protection occupies a high proportion, which makes the research of coatings in seawater environments a hot spot.

Through the modification of the coating itself and the coating attachment matrix, the effect of improving the service life of the coating and improving the quality of the protection of the coating is achieved. Compared with the traditional modification technology, the plasma treatment of atmospheric plasma machine has the characteristics of environmental protection, no pollution, no damage to the overall nature of the body surface, wide application range, and safety.

In terms of surface modification of the substrate, plasma treatment is applied to the substrate. After plasma treatment, functional groups for connectivity are added to the surface of the substrate, such as hydroxyl (-OH), carbonyl (-CO) and other functional groups. These functional groups can react with the unsaturated double bond (-C=C-), carboxyl (R-OOH), hydroxyl R-OH, aliphatic (R-OOR) and other functional groups in the alkyd resin to form chemical bonds to improve the coating Bonding force with the substrate.

In addition, plasma treatment with atmospheric plasma machine can also increase the surface roughness and increase the bonding force from the physical aspect. Electrochemical impedance (EIS) and scanning Kelvin probe test (SKP) results have proved that plasma treatment can enhance the protective performance of the coating and delay the failure of the coating.

In order to improve the water seepage and corrosion resistance of the coating itself, nano-scale multi-walled carbon nanotubes are added to the varnish to act as pigments and fillers. The addition of carbon nanotubes increases the compactness of the film-forming coating, fills the channels for water molecules to penetrate, significantly prolongs the time it takes for water to penetrate from the coating surface to the substrate surface, delays the coating failure, and increases the service life of the coating.

Analyze from the perspective of molecular mechanics. By simulating the plasma treatment on the surface of the iron substrate, the changes in the adsorption energy of the alkyd resin on the surface of the untreated iron substrate and the surface of the iron substrate treated by an atmospheric plasma machine are compared. The results prove that plasma treatment on the surface of the iron substrate can promote the adsorption of alkyd resin on the surface of the substrate.

The effect of plasma surface treatment and carbon nanotube filler on the failure of the varnish coating can improve the protective effect of the coating and increase the life of the coating.

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-11-03 22:16

- Views:

The effect of carbon nanotube filler on the failure of varnish coating by surface treatment of atmospheric plasma machine:

In the natural environment, materials will undergo chemical or electrochemical effects due to environmental influences, which will cause corrosion failure, lose their original mechanical properties and structural effects, and cause potential safety hazards and economic losses.

Corrosion in the atmospheric environment, soil environment and marine environment is highlighted by marine corrosion. In terms of marine corrosion protection, paint protection occupies a high proportion, which makes the research of coatings in seawater environments a hot spot.

Corrosion in the atmospheric environment, soil environment and marine environment is highlighted by marine corrosion. In terms of marine corrosion protection, paint protection occupies a high proportion, which makes the research of coatings in seawater environments a hot spot.

Through the modification of the coating itself and the coating attachment matrix, the effect of improving the service life of the coating and improving the quality of the protection of the coating is achieved. Compared with the traditional modification technology, the plasma treatment of atmospheric plasma machine has the characteristics of environmental protection, no pollution, no damage to the overall nature of the body surface, wide application range, and safety.

In terms of surface modification of the substrate, plasma treatment is applied to the substrate. After plasma treatment, functional groups for connectivity are added to the surface of the substrate, such as hydroxyl (-OH), carbonyl (-CO) and other functional groups. These functional groups can react with the unsaturated double bond (-C=C-), carboxyl (R-OOH), hydroxyl R-OH, aliphatic (R-OOR) and other functional groups in the alkyd resin to form chemical bonds to improve the coating Bonding force with the substrate.

In addition, plasma treatment with atmospheric plasma machine can also increase the surface roughness and increase the bonding force from the physical aspect. Electrochemical impedance (EIS) and scanning Kelvin probe test (SKP) results have proved that plasma treatment can enhance the protective performance of the coating and delay the failure of the coating.

In order to improve the water seepage and corrosion resistance of the coating itself, nano-scale multi-walled carbon nanotubes are added to the varnish to act as pigments and fillers. The addition of carbon nanotubes increases the compactness of the film-forming coating, fills the channels for water molecules to penetrate, significantly prolongs the time it takes for water to penetrate from the coating surface to the substrate surface, delays the coating failure, and increases the service life of the coating.

Analyze from the perspective of molecular mechanics. By simulating the plasma treatment on the surface of the iron substrate, the changes in the adsorption energy of the alkyd resin on the surface of the untreated iron substrate and the surface of the iron substrate treated by an atmospheric plasma machine are compared. The results prove that plasma treatment on the surface of the iron substrate can promote the adsorption of alkyd resin on the surface of the substrate.

The effect of plasma surface treatment and carbon nanotube filler on the failure of the varnish coating can improve the protective effect of the coating and increase the life of the coating.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen