Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

The etching of wafer circuit board plasma cleaning machine is applied in the circuit board industry

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-10-25

- Views:

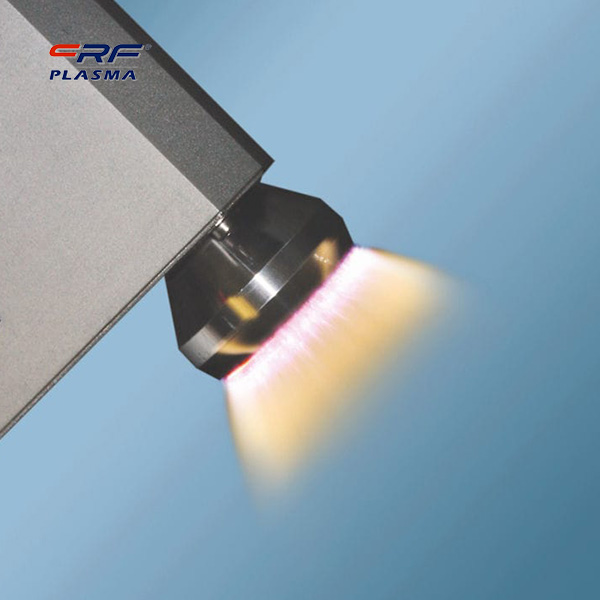

(Summary description)The etching of wafer circuit board plasma cleaning machine is applied in the circuit board industry: Most of the gases used in plasma etching are fluorine-containing gases, of which carbon tetrafluoride is the main one. Plasma cleaner etching is widely used in wafer manufacturing and circuit board manufacturing. Application of wafer manufacturing industry: In the wafer manufacturing industry, photoetchers use tetrafluorocarbon gas to etch silicon wafers, and plasma cleaners use tetrafluorocarbon gas to etch silicon nitride and remove photoresist. Plasma etching uses pure carbon tetrafluoride gas or the combination of carbon tetrafluoride and oxygen to perform micron-level etching on silicon nitride during the wafer manufacturing process. Under the combination of hydrogen and oxygen, the micron is removed. Grade photoresist. Application of circuit board plasma cleaning manufacturing industry: The etching of plasma cleaning machine has been applied very early in the circuit board industry. Whether it is a rigid circuit board or a flexible circuit board, the phenomenon of glue removal in the hole will occur during the production process. The traditional processing method is to use chemical agents to clean, but with With the development of the circuit board industry, the boards are made smaller and smaller, and the holes become smaller. It is more and more difficult to remove glue in the chemical cleaning holes. Also, the smaller the hole, the erosion amount is difficult to control, and chemical residues will be generated. Affect the subsequent processing. However, the etching of the plasma cleaner is dry, there is no chemical residue, and the plasma has a very strong diffusion ability. The generated etch gas-phase plasma can be effectively etched in the micron-level holes, and the amount of biting is It can also be controlled by adjusting the process parameters. Chengfeng Zhizhi has focused on the research and development of plasma cleaning machines for 20 years. If you want to know more product details or have questions about the use of the equipment, please click on Chengfeng Zhizhi online customer service, waiting for your call!

The etching of wafer circuit board plasma cleaning machine is applied in the circuit board industry

(Summary description)The etching of wafer circuit board plasma cleaning machine is applied in the circuit board industry:

Most of the gases used in plasma etching are fluorine-containing gases, of which carbon tetrafluoride is the main one. Plasma cleaner etching is widely used in wafer manufacturing and circuit board manufacturing.

Application of wafer manufacturing industry:

In the wafer manufacturing industry, photoetchers use tetrafluorocarbon gas to etch silicon wafers, and plasma cleaners use tetrafluorocarbon gas to etch silicon nitride and remove photoresist. Plasma etching uses pure carbon tetrafluoride gas or the combination of carbon tetrafluoride and oxygen to perform micron-level etching on silicon nitride during the wafer manufacturing process. Under the combination of hydrogen and oxygen, the micron is removed. Grade photoresist.

Application of circuit board plasma cleaning manufacturing industry:

The etching of plasma cleaning machine has been applied very early in the circuit board industry. Whether it is a rigid circuit board or a flexible circuit board, the phenomenon of glue removal in the hole will occur during the production process. The traditional processing method is to use chemical agents to clean, but with With the development of the circuit board industry, the boards are made smaller and smaller, and the holes become smaller. It is more and more difficult to remove glue in the chemical cleaning holes. Also, the smaller the hole, the erosion amount is difficult to control, and chemical residues will be generated. Affect the subsequent processing. However, the etching of the plasma cleaner is dry, there is no chemical residue, and the plasma has a very strong diffusion ability. The generated etch gas-phase plasma can be effectively etched in the micron-level holes, and the amount of biting is It can also be controlled by adjusting the process parameters.

Chengfeng Zhizhi has focused on the research and development of plasma cleaning machines for 20 years. If you want to know more product details or have questions about the use of the equipment, please click on Chengfeng Zhizhi online customer service, waiting for your call!

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-10-25 20:47

- Views:

The etching of wafer circuit board plasma cleaning machine is applied in the circuit board industry:

Most of the gases used in plasma etching are fluorine-containing gases, of which carbon tetrafluoride is the main one. Plasma cleaner etching is widely used in wafer manufacturing and circuit board manufacturing.

Application of wafer manufacturing industry:

Application of wafer manufacturing industry:

In the wafer manufacturing industry, photoetchers use tetrafluorocarbon gas to etch silicon wafers, and plasma cleaners use tetrafluorocarbon gas to etch silicon nitride and remove photoresist. Plasma etching uses pure carbon tetrafluoride gas or the combination of carbon tetrafluoride and oxygen to perform micron-level etching on silicon nitride during the wafer manufacturing process. Under the combination of hydrogen and oxygen, the micron is removed. Grade photoresist.

Application of circuit board plasma cleaning manufacturing industry:

The etching of plasma cleaning machine has been applied very early in the circuit board industry. Whether it is a rigid circuit board or a flexible circuit board, the phenomenon of glue removal in the hole will occur during the production process. The traditional processing method is to use chemical agents to clean, but with With the development of the circuit board industry, the boards are made smaller and smaller, and the holes become smaller. It is more and more difficult to remove glue in the chemical cleaning holes. Also, the smaller the hole, the erosion amount is difficult to control, and chemical residues will be generated. Affect the subsequent processing. However, the etching of the plasma cleaner is dry, there is no chemical residue, and the plasma has a very strong diffusion ability. The generated etch gas-phase plasma can be effectively etched in the micron-level holes, and the amount of biting is It can also be controlled by adjusting the process parameters.

Chengfeng Zhizhi has focused on the research and development of plasma cleaning machines for 20 years. If you want to know more product details or have questions about the use of the equipment, please click on Chengfeng Zhizhi online customer service, waiting for your call!

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen