Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

The application of plasma generator in the treatment of adhesion and proliferation of PEGDA-based gel surface

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-10-16

- Views:

(Summary description)The application of plasma generator in the treatment of adhesion and proliferation of PEGDA-based gel surface: The adhesion of target cells to biological materials is a prerequisite for the construction of tissue-engineered organs. Materials with good cell compatibility provide a good extracellular growth environment for cells, and maintain the normal phenotype and physiological functions of cells, and realize the restoration of tissue or organ structure and function. Polyethylene glycol (PEG) is a non-degradable polymer biomaterial approved by the US FDA. It has hydrophilicity, biocompatibility, and inhibits protein adsorption and cell adhesion. Low-molecular-weight PEG can be swallowed by phagocytes or excreted through the kidney membrane. Although the surface of the PEG-loaded material has good biocompatibility, it is difficult for cells to adhere to the surface of the material due to its resistance to proteins and cells. And growth. Therefore, the PEG substrate is activated and modified by introducing active groups, so that it can be used to construct desired biological functional materials. The chemical functional groups on the surface of biological materials (such as hydroxyl, amine, carboxyl, carbonyl, amide, etc.) have an important impact on cell compatibility and affect the hydrophilicity and hydrophobicity of the material. The hydroxy Z methacrylate monomer with active hydroxyl groups was introduced into the polyethylene glycol diacrylate substrate. The research results show that the hydroxyl groups are beneficial to cell adhesion and spreading, thereby improving the cells of PEGDA-based gel materials. Affinity; On the other hand, the surface energy of the material has an important effect on cell compatibility. It is generally believed that higher surface energy is beneficial to cell adhesion, spreading and proliferation. The use of plasma generator glow discharge surface modification technology can improve some Polar oxygen-containing and nitrogen-containing groups (such as amino and amide groups) are introduced into the surface of chemically inert materials to improve their biocompatibility. The surface roughness of the material after plasma treatment by the plasma generator is increased, and the increased surface can enhance the cell affinity of the material. After the material is plasma treated, due to the action of free radicals, electrons and ions in the plasma, the chemical bonds on the surface of the material are broken to form new chemical bonds, and the distribution of electrons near the elements also changes. The interaction between cells and matrix materials is the main field of tissue engineering research. Among them, the adhesion of cells and materials is the basis. Cells must properly adhere to the materials in order to migrate, proliferate and differentiate. The surface roughness and hydrophobicity of the materials are related to The surface energy of materials is closely related, which affects cell adhesion and proliferation. After the plasma surface treatment by the plasma generator, the surface of the membrane material is rougher than that before treatment, with uneven, undulating height, which can increase the surface area of the contact between the cells and the material, and at the same time facilitate the extension of the filopodia at the cell protrusions. The filopodia are beneficial to the adhesion and spreading of cells on the surface of the material. After the material is treated with plasma, the hydrophilicity and surface energy of the material are greatly enhanced, which promotes the wetting effect of the cells on the surface of the material, and the rough surface improves the adhesion of the cells. The material modified by the plasma generator ion surface showed better cell proliferation than the unmodified membrane surface, and the cell adhesion rate was increased. The proliferation of the material after plasma treatment was generally more active than that before the treatment, and the plasma treatment condensed The film material is more conducive to the proliferation and growth of BMS on the material. Plasma-treated materials have stronger cell adaptability than untreated materials, have a higher adhesion rate, vigorous proliferation in vitro, stable growth characteristics, and form a network structure.

The application of plasma generator in the treatment of adhesion and proliferation of PEGDA-based gel surface

(Summary description)The application of plasma generator in the treatment of adhesion and proliferation of PEGDA-based gel surface:

The adhesion of target cells to biological materials is a prerequisite for the construction of tissue-engineered organs. Materials with good cell compatibility provide a good extracellular growth environment for cells, and maintain the normal phenotype and physiological functions of cells, and realize the restoration of tissue or organ structure and function.

Polyethylene glycol (PEG) is a non-degradable polymer biomaterial approved by the US FDA. It has hydrophilicity, biocompatibility, and inhibits protein adsorption and cell adhesion. Low-molecular-weight PEG can be swallowed by phagocytes or excreted through the kidney membrane. Although the surface of the PEG-loaded material has good biocompatibility, it is difficult for cells to adhere to the surface of the material due to its resistance to proteins and cells. And growth. Therefore, the PEG substrate is activated and modified by introducing active groups, so that it can be used to construct desired biological functional materials.

The chemical functional groups on the surface of biological materials (such as hydroxyl, amine, carboxyl, carbonyl, amide, etc.) have an important impact on cell compatibility and affect the hydrophilicity and hydrophobicity of the material. The hydroxy Z methacrylate monomer with active hydroxyl groups was introduced into the polyethylene glycol diacrylate substrate. The research results show that the hydroxyl groups are beneficial to cell adhesion and spreading, thereby improving the cells of PEGDA-based gel materials. Affinity;

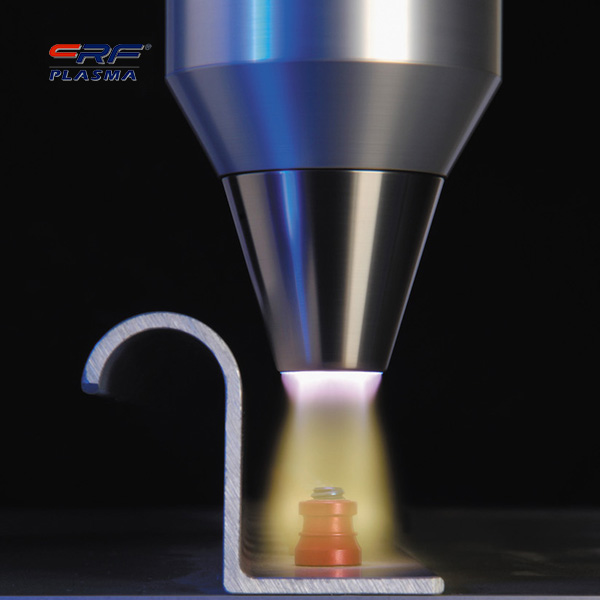

On the other hand, the surface energy of the material has an important effect on cell compatibility. It is generally believed that higher surface energy is beneficial to cell adhesion, spreading and proliferation. The use of plasma generator glow discharge surface modification technology can improve some Polar oxygen-containing and nitrogen-containing groups (such as amino and amide groups) are introduced into the surface of chemically inert materials to improve their biocompatibility. The surface roughness of the material after plasma treatment by the plasma generator is increased, and the increased surface can enhance the cell affinity of the material. After the material is plasma treated, due to the action of free radicals, electrons and ions in the plasma, the chemical bonds on the surface of the material are broken to form new chemical bonds, and the distribution of electrons near the elements also changes.

The interaction between cells and matrix materials is the main field of tissue engineering research. Among them, the adhesion of cells and materials is the basis. Cells must properly adhere to the materials in order to migrate, proliferate and differentiate. The surface roughness and hydrophobicity of the materials are related to The surface energy of materials is closely related, which affects cell adhesion and proliferation.

After the plasma surface treatment by the plasma generator, the surface of the membrane material is rougher than that before treatment, with uneven, undulating height, which can increase the surface area of the contact between the cells and the material, and at the same time facilitate the extension of the filopodia at the cell protrusions. The filopodia are beneficial to the adhesion and spreading of cells on the surface of the material.

After the material is treated with plasma, the hydrophilicity and surface energy of the material are greatly enhanced, which promotes the wetting effect of the cells on the surface of the material, and the rough surface improves the adhesion of the cells. The material modified by the plasma generator ion surface showed better cell proliferation than the unmodified membrane surface, and the cell adhesion rate was increased. The proliferation of the material after plasma treatment was generally more active than that before the treatment, and the plasma treatment condensed The film material is more conducive to the proliferation and growth of BMS on the material.

Plasma-treated materials have stronger cell adaptability than untreated materials, have a higher adhesion rate, vigorous proliferation in vitro, stable growth characteristics, and form a network structure.

- Categories:Company Dynamics

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-10-16 21:14

- Views:

The application of plasma generator in the treatment of adhesion and proliferation of PEGDA-based gel surface:

The adhesion of target cells to biological materials is a prerequisite for the construction of tissue-engineered organs. Materials with good cell compatibility provide a good extracellular growth environment for cells, and maintain the normal phenotype and physiological functions of cells, and realize the restoration of tissue or organ structure and function.

Polyethylene glycol (PEG) is a non-degradable polymer biomaterial approved by the US FDA. It has hydrophilicity, biocompatibility, and inhibits protein adsorption and cell adhesion. Low-molecular-weight PEG can be swallowed by phagocytes or excreted through the kidney membrane. Although the surface of the PEG-loaded material has good biocompatibility, it is difficult for cells to adhere to the surface of the material due to its resistance to proteins and cells. And growth. Therefore, the PEG substrate is activated and modified by introducing active groups, so that it can be used to construct desired biological functional materials.

The chemical functional groups on the surface of biological materials (such as hydroxyl, amine, carboxyl, carbonyl, amide, etc.) have an important impact on cell compatibility and affect the hydrophilicity and hydrophobicity of the material. The hydroxy Z methacrylate monomer with active hydroxyl groups was introduced into the polyethylene glycol diacrylate substrate. The research results show that the hydroxyl groups are beneficial to cell adhesion and spreading, thereby improving the cells of PEGDA-based gel materials. Affinity;

The chemical functional groups on the surface of biological materials (such as hydroxyl, amine, carboxyl, carbonyl, amide, etc.) have an important impact on cell compatibility and affect the hydrophilicity and hydrophobicity of the material. The hydroxy Z methacrylate monomer with active hydroxyl groups was introduced into the polyethylene glycol diacrylate substrate. The research results show that the hydroxyl groups are beneficial to cell adhesion and spreading, thereby improving the cells of PEGDA-based gel materials. Affinity;

On the other hand, the surface energy of the material has an important effect on cell compatibility. It is generally believed that higher surface energy is beneficial to cell adhesion, spreading and proliferation. The use of plasma generator glow discharge surface modification technology can improve some Polar oxygen-containing and nitrogen-containing groups (such as amino and amide groups) are introduced into the surface of chemically inert materials to improve their biocompatibility. The surface roughness of the material after plasma treatment by the plasma generator is increased, and the increased surface can enhance the cell affinity of the material. After the material is plasma treated, due to the action of free radicals, electrons and ions in the plasma, the chemical bonds on the surface of the material are broken to form new chemical bonds, and the distribution of electrons near the elements also changes.

The interaction between cells and matrix materials is the main field of tissue engineering research. Among them, the adhesion of cells and materials is the basis. Cells must properly adhere to the materials in order to migrate, proliferate and differentiate. The surface roughness and hydrophobicity of the materials are related to The surface energy of materials is closely related, which affects cell adhesion and proliferation.

After the plasma surface treatment by the plasma generator, the surface of the membrane material is rougher than that before treatment, with uneven, undulating height, which can increase the surface area of the contact between the cells and the material, and at the same time facilitate the extension of the filopodia at the cell protrusions. The filopodia are beneficial to the adhesion and spreading of cells on the surface of the material.

After the material is treated with plasma, the hydrophilicity and surface energy of the material are greatly enhanced, which promotes the wetting effect of the cells on the surface of the material, and the rough surface improves the adhesion of the cells. The material modified by the plasma generator ion surface showed better cell proliferation than the unmodified membrane surface, and the cell adhesion rate was increased. The proliferation of the material after plasma treatment was generally more active than that before the treatment, and the plasma treatment condensed The film material is more conducive to the proliferation and growth of BMS on the material.

Plasma-treated materials have stronger cell adaptability than untreated materials, have a higher adhesion rate, vigorous proliferation in vitro, stable growth characteristics, and form a network structure.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen