Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

In the early days, what surface treatment methods would be used for plastic materials without plasma flame machine

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-09-29

- Views:

(Summary description)In the early days, what surface treatment methods would be used for plastic materials without plasma flame machine: In terms of materials, if the material itself has no polarity, the surface tension of the material will be very low, and printing, ink, bonding, coating and other processes are difficult to complete, or the actual effect is poor. Plastic material is such a material with low surface tension. Everyone knows that surface treatment with a plasma flame machine is helpful. Do you know how to solve the problem of printing and printing plastic materials before the popularization of plasma flame machines? What about process issues such as bonding? In the early stage of the industry, due to the limitations of materials and processes, rubber and plastic products are generally accommodating materials in the production process. Which materials can meet the requirements of spraying, bonding and other processes will give priority to which materials are used. Over time , The problem of material cost gradually emerged, prompting manufacturers to start looking for rubber and plastic materials with better performance and lower cost, as well as suitable material surface treatment methods. Earlier, the non-plasma flame machine's surface treatment method was a simple grinding machine and an environmentally friendly water-based coating treatment method. The actual effect that can be achieved is very limited, and it is still difficult to get rid of the dependence on the performance of the material itself. Since then, the fluorination treatment method has been selected. The treatment effect of this surface treatment method is significantly improved, but it will generate a large amount of harmful gas and increase the input cost of waste gas treatment. Although the problem of the process effect of fluorination treatment has been solved, the production Cost and safety and environmental protection still exist. Chengfeng Zhizhi has focused on the research and development of plasma flame machines for 20 years. If you want to know more product details or have questions about the use of equipment, please click on Chengfeng Zhizhi online customer service, waiting for your call!

In the early days, what surface treatment methods would be used for plastic materials without plasma flame machine

(Summary description)In the early days, what surface treatment methods would be used for plastic materials without plasma flame machine:

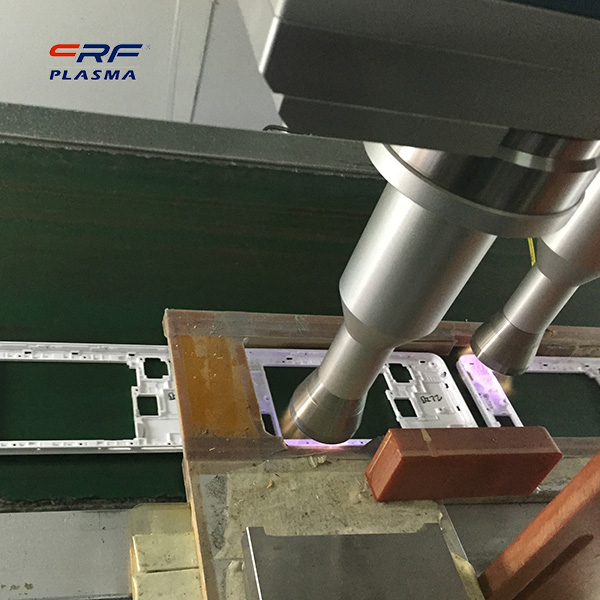

In terms of materials, if the material itself has no polarity, the surface tension of the material will be very low, and printing, ink, bonding, coating and other processes are difficult to complete, or the actual effect is poor. Plastic material is such a material with low surface tension. Everyone knows that surface treatment with a plasma flame machine is helpful. Do you know how to solve the problem of printing and printing plastic materials before the popularization of plasma flame machines? What about process issues such as bonding?

In the early stage of the industry, due to the limitations of materials and processes, rubber and plastic products are generally accommodating materials in the production process. Which materials can meet the requirements of spraying, bonding and other processes will give priority to which materials are used. Over time , The problem of material cost gradually emerged, prompting manufacturers to start looking for rubber and plastic materials with better performance and lower cost, as well as suitable material surface treatment methods.

Earlier, the non-plasma flame machine's surface treatment method was a simple grinding machine and an environmentally friendly water-based coating treatment method. The actual effect that can be achieved is very limited, and it is still difficult to get rid of the dependence on the performance of the material itself. Since then, the fluorination treatment method has been selected. The treatment effect of this surface treatment method is significantly improved, but it will generate a large amount of harmful gas and increase the input cost of waste gas treatment. Although the problem of the process effect of fluorination treatment has been solved, the production Cost and safety and environmental protection still exist.

Chengfeng Zhizhi has focused on the research and development of plasma flame machines for 20 years. If you want to know more product details or have questions about the use of equipment, please click on Chengfeng Zhizhi online customer service, waiting for your call!

- Categories:Industry News

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-09-29 22:02

- Views:

In the early days, what surface treatment methods would be used for plastic materials without plasma flame machine:

In terms of materials, if the material itself has no polarity, the surface tension of the material will be very low, and printing, ink, bonding, coating and other processes are difficult to complete, or the actual effect is poor. Plastic material is such a material with low surface tension. Everyone knows that surface treatment with a plasma flame machine is helpful. Do you know how to solve the problem of printing and printing plastic materials before the popularization of plasma flame machines? What about process issues such as bonding?

In the early stage of the industry, due to the limitations of materials and processes, rubber and plastic products are generally accommodating materials in the production process. Which materials can meet the requirements of spraying, bonding and other processes will give priority to which materials are used. Over time , The problem of material cost gradually emerged, prompting manufacturers to start looking for rubber and plastic materials with better performance and lower cost, as well as suitable material surface treatment methods.

In the early stage of the industry, due to the limitations of materials and processes, rubber and plastic products are generally accommodating materials in the production process. Which materials can meet the requirements of spraying, bonding and other processes will give priority to which materials are used. Over time , The problem of material cost gradually emerged, prompting manufacturers to start looking for rubber and plastic materials with better performance and lower cost, as well as suitable material surface treatment methods.

Earlier, the non-plasma flame machine's surface treatment method was a simple grinding machine and an environmentally friendly water-based coating treatment method. The actual effect that can be achieved is very limited, and it is still difficult to get rid of the dependence on the performance of the material itself. Since then, the fluorination treatment method has been selected. The treatment effect of this surface treatment method is significantly improved, but it will generate a large amount of harmful gas and increase the input cost of waste gas treatment. Although the problem of the process effect of fluorination treatment has been solved, the production Cost and safety and environmental protection still exist.

Chengfeng Zhizhi has focused on the research and development of plasma flame machines for 20 years. If you want to know more product details or have questions about the use of equipment, please click on Chengfeng Zhizhi online customer service, waiting for your call!

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen