Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

What is the difference in the dry treatment of the plastic material surface of the plasma cleaning instrument equipmen

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-07-18

- Views:

(Summary description)What is the difference in the dry treatment of the plastic material surface of the plasma cleaning instrument equipment: Compared with the earlier polishing and water-based paint treatments, the surface treatment of rubber and plastic materials usually adopts wet treatment and plasma cleaning equipment dry treatment. The wet treatment is mainly processed by chemical reagents and solvents. The surface of the material, and the plasma cleaner equipment is a typical dry treatment method, which does not require solvents and chemicals. What is the difference between these two methods? Wet processing generally uses chemical agents to treat materials to improve the effects of processes such as plastic-plastic material bonding. However, chemical agents are difficult to operate and difficult to control during use. They may damage the materials and affect the performance of the materials. The entire processing process still needs Consume a lot of water resources and produce wastewater pollution. The content of the surface treatment method of plasma cleaning equipment is not repeated here. You can refer to the previous related articles. With the application of low-temperature plasma surface treatment technology, the types of materials selected in the rubber and plastic industries are also increasing. , Not only PP, PC, ABS and other materials, but also various elastomers and composite materials are also widely used. The drying treatment of the plasma cleaner equipment can make the surface of the material rough, and introduce active groups on the surface of the material to increase the surface energy and improve the effects of printing, bonding, coating, etc. The dry treatment technology of plasma cleaner equipment has been promoted and developed under the current market and policy environment. The reason is not only that the technology can meet many high-standard process requirements, but also because the surface treatment is simple to operate on rubber and plastic materials. The treatment effect is good, the treatment efficiency is high, the operating cost is low, and no harmful substances are generated before and after treatment.

What is the difference in the dry treatment of the plastic material surface of the plasma cleaning instrument equipmen

(Summary description)What is the difference in the dry treatment of the plastic material surface of the plasma cleaning instrument equipment:

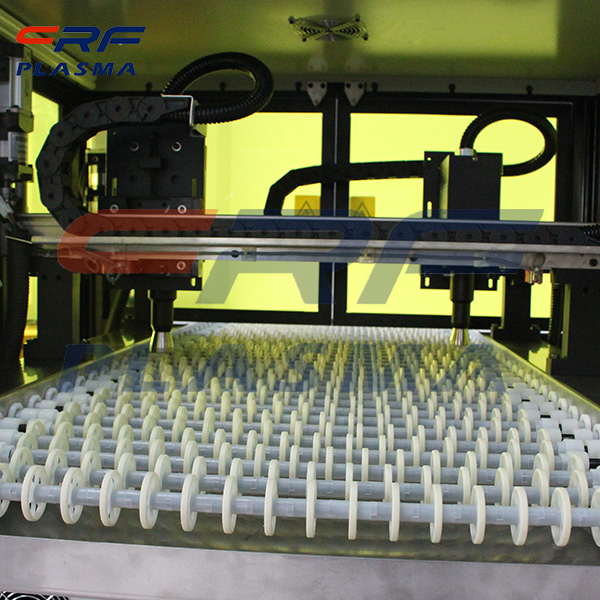

Compared with the earlier polishing and water-based paint treatments, the surface treatment of rubber and plastic materials usually adopts wet treatment and plasma cleaning equipment dry treatment. The wet treatment is mainly processed by chemical reagents and solvents. The surface of the material, and the plasma cleaner equipment is a typical dry treatment method, which does not require solvents and chemicals. What is the difference between these two methods?

Wet processing generally uses chemical agents to treat materials to improve the effects of processes such as plastic-plastic material bonding. However, chemical agents are difficult to operate and difficult to control during use. They may damage the materials and affect the performance of the materials. The entire processing process still needs Consume a lot of water resources and produce wastewater pollution.

The content of the surface treatment method of plasma cleaning equipment is not repeated here. You can refer to the previous related articles. With the application of low-temperature plasma surface treatment technology, the types of materials selected in the rubber and plastic industries are also increasing. , Not only PP, PC, ABS and other materials, but also various elastomers and composite materials are also widely used. The drying treatment of the plasma cleaner equipment can make the surface of the material rough, and introduce active groups on the surface of the material to increase the surface energy and improve the effects of printing, bonding, coating, etc.

The dry treatment technology of plasma cleaner equipment has been promoted and developed under the current market and policy environment. The reason is not only that the technology can meet many high-standard process requirements, but also because the surface treatment is simple to operate on rubber and plastic materials. The treatment effect is good, the treatment efficiency is high, the operating cost is low, and no harmful substances are generated before and after treatment.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-07-18 08:59

- Views:

What is the difference in the dry treatment of the plastic material surface of the plasma cleaning instrument equipment:

Compared with the earlier polishing and water-based paint treatments, the surface treatment of rubber and plastic materials usually adopts wet treatment and plasma cleaning equipment dry treatment. The wet treatment is mainly processed by chemical reagents and solvents. The surface of the material, and the plasma cleaner equipment is a typical dry treatment method, which does not require solvents and chemicals. What is the difference between these two methods?

Wet processing generally uses chemical agents to treat materials to improve the effects of processes such as plastic-plastic material bonding. However, chemical agents are difficult to operate and difficult to control during use. They may damage the materials and affect the performance of the materials. The entire processing process still needs Consume a lot of water resources and produce wastewater pollution.

Wet processing generally uses chemical agents to treat materials to improve the effects of processes such as plastic-plastic material bonding. However, chemical agents are difficult to operate and difficult to control during use. They may damage the materials and affect the performance of the materials. The entire processing process still needs Consume a lot of water resources and produce wastewater pollution.

The content of the surface treatment method of plasma cleaning equipment is not repeated here. You can refer to the previous related articles. With the application of low-temperature plasma surface treatment technology, the types of materials selected in the rubber and plastic industries are also increasing. , Not only PP, PC, ABS and other materials, but also various elastomers and composite materials are also widely used. The drying treatment of the plasma cleaner equipment can make the surface of the material rough, and introduce active groups on the surface of the material to increase the surface energy and improve the effects of printing, bonding, coating, etc.

The dry treatment technology of plasma cleaner equipment has been promoted and developed under the current market and policy environment. The reason is not only that the technology can meet many high-standard process requirements, but also because the surface treatment is simple to operate on rubber and plastic materials. The treatment effect is good, the treatment efficiency is high, the operating cost is low, and no harmful substances are generated before and after treatment.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen