Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

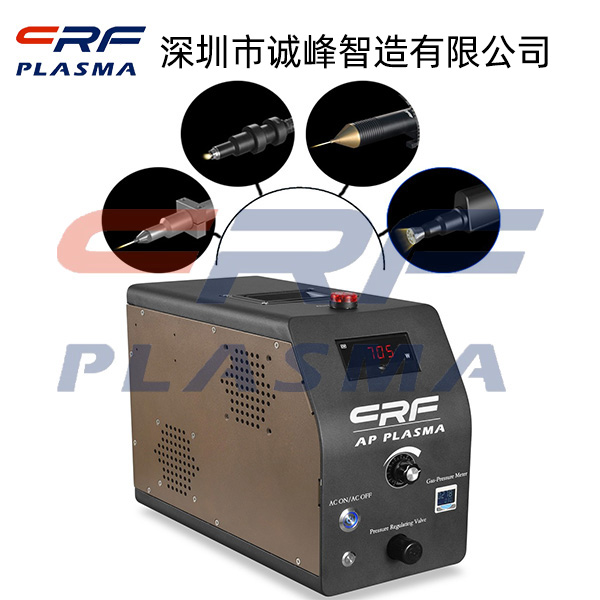

Application in surface treatment of plasma equipment for processing metal materials

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-07-15

- Views:

(Summary description)Application in surface treatment of plasma equipment for processing metal materials: When processing metal materials, plasma equipment can change the inherent surface mechanical properties of metal materials, improve various properties of metal materials, such as wear resistance, corrosion resistance, etc., and improve adhesion. What aspects of metal materials can plasma equipment specifically solve? Removal of oil stains and other dirt on the surface of metal materials by plasma equipment: Plasma cleaning technology is used to process metal materials, which can make the surface of metal materials easy to adhere to residues such as oil stains and oxides. Plasma treatment can remove contaminants and oil stains on the surface of various metal materials to form a clean surface. Plasma equipment improves the adhesion and welding strength between metal and other materials: It can react with the metal surface at nanometer level, and through the physical bombardment of particles and molecular chemical reaction, the metal surface becomes micro-rough and clean, thereby improving the adhesion and welding strength between the surface of the metal material and other materials. It helps to improve the effect of subsequent bonding, spraying, printing, and welding, and can remove static electricity on the surface of the material. Plasma equipment can improve the corrosion resistance and wear resistance of metal surfaces: Plasma surface treatment is used to cover the metal surface with a layer of anti-corrosion material to prevent the metal material from contacting external water molecules and acid-base substances, thereby improving the anti-corrosion ability of the metal material surface. In addition, in the printed circuit board industry, plasma is also required to remove the chemical flux used in soldering, otherwise this substance is prone to corrosion. Similar to the improvement of anti-corrosion ability, the improvement of metal surface hardness and wear resistance also form a layer of substance on the metal surface, which improves the hardness and wear resistance, making it harder and more wear-resistant. Processing of plasma equipment for metal special-shaped parts: Plasma equipment will inevitably encounter some special-shaped parts when surface treatment of metal materials. Its surface treatment has good diffusion and unevenness, high treatment efficiency and good uniformity, which is suitable for most metal specifications Batch processing of special-shaped parts.

Application in surface treatment of plasma equipment for processing metal materials

(Summary description)Application in surface treatment of plasma equipment for processing metal materials:

When processing metal materials, plasma equipment can change the inherent surface mechanical properties of metal materials, improve various properties of metal materials, such as wear resistance, corrosion resistance, etc., and improve adhesion. What aspects of metal materials can plasma equipment specifically solve?

Removal of oil stains and other dirt on the surface of metal materials by plasma equipment:

Plasma cleaning technology is used to process metal materials, which can make the surface of metal materials easy to adhere to residues such as oil stains and oxides. Plasma treatment can remove contaminants and oil stains on the surface of various metal materials to form a clean surface.

Plasma equipment improves the adhesion and welding strength between metal and other materials:

It can react with the metal surface at nanometer level, and through the physical bombardment of particles and molecular chemical reaction, the metal surface becomes micro-rough and clean, thereby improving the adhesion and welding strength between the surface of the metal material and other materials. It helps to improve the effect of subsequent bonding, spraying, printing, and welding, and can remove static electricity on the surface of the material.

Plasma equipment can improve the corrosion resistance and wear resistance of metal surfaces:

Plasma surface treatment is used to cover the metal surface with a layer of anti-corrosion material to prevent the metal material from contacting external water molecules and acid-base substances, thereby improving the anti-corrosion ability of the metal material surface. In addition, in the printed circuit board industry, plasma is also required to remove the chemical flux used in soldering, otherwise this substance is prone to corrosion.

Similar to the improvement of anti-corrosion ability, the improvement of metal surface hardness and wear resistance also form a layer of substance on the metal surface, which improves the hardness and wear resistance, making it harder and more wear-resistant.

Processing of plasma equipment for metal special-shaped parts:

Plasma equipment will inevitably encounter some special-shaped parts when surface treatment of metal materials. Its surface treatment has good diffusion and unevenness, high treatment efficiency and good uniformity, which is suitable for most metal specifications Batch processing of special-shaped parts.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-07-15 08:51

- Views:

Application in surface treatment of plasma equipment for processing metal materials:

When processing metal materials, plasma equipment can change the inherent surface mechanical properties of metal materials, improve various properties of metal materials, such as wear resistance, corrosion resistance, etc., and improve adhesion. What aspects of metal materials can plasma equipment specifically solve?

When processing metal materials, plasma equipment can change the inherent surface mechanical properties of metal materials, improve various properties of metal materials, such as wear resistance, corrosion resistance, etc., and improve adhesion. What aspects of metal materials can plasma equipment specifically solve?

Removal of oil stains and other dirt on the surface of metal materials by plasma equipment:

Plasma cleaning technology is used to process metal materials, which can make the surface of metal materials easy to adhere to residues such as oil stains and oxides. Plasma treatment can remove contaminants and oil stains on the surface of various metal materials to form a clean surface.

Plasma equipment improves the adhesion and welding strength between metal and other materials:

It can react with the metal surface at nanometer level, and through the physical bombardment of particles and molecular chemical reaction, the metal surface becomes micro-rough and clean, thereby improving the adhesion and welding strength between the surface of the metal material and other materials. It helps to improve the effect of subsequent bonding, spraying, printing, and welding, and can remove static electricity on the surface of the material.

Plasma equipment can improve the corrosion resistance and wear resistance of metal surfaces:

Plasma surface treatment is used to cover the metal surface with a layer of anti-corrosion material to prevent the metal material from contacting external water molecules and acid-base substances, thereby improving the anti-corrosion ability of the metal material surface. In addition, in the printed circuit board industry, plasma is also required to remove the chemical flux used in soldering, otherwise this substance is prone to corrosion.

Similar to the improvement of anti-corrosion ability, the improvement of metal surface hardness and wear resistance also form a layer of substance on the metal surface, which improves the hardness and wear resistance, making it harder and more wear-resistant.

Processing of plasma equipment for metal special-shaped parts:

Plasma equipment will inevitably encounter some special-shaped parts when surface treatment of metal materials. Its surface treatment has good diffusion and unevenness, high treatment efficiency and good uniformity, which is suitable for most metal specifications Batch processing of special-shaped parts.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen