Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

What effect does the sputtering phenomenon of the vacuum plasma processor have on the product

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-06-29

- Views:

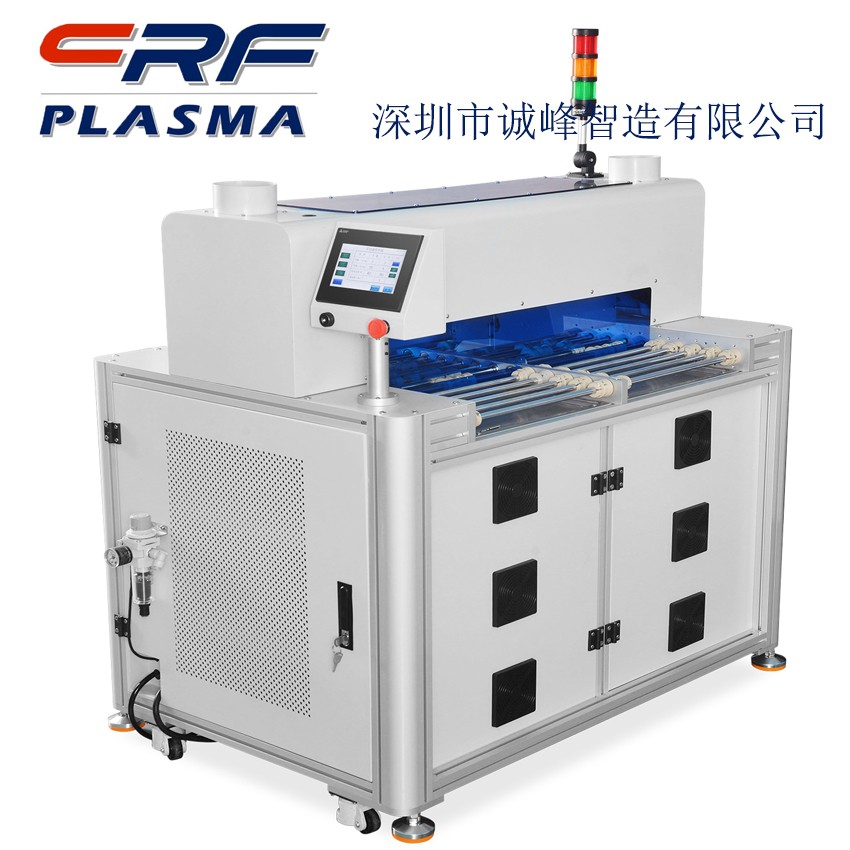

(Summary description)What effect does the sputtering phenomenon of the vacuum plasma processor have on the product: When using a compatible coupling discharge vacuum plasma processor for surface treatment of material plasma, as long as the selected gas is an inert gas, a certain sputtering phenomenon will occur, which is actually independent of DC glow discharge or AC high-frequency discharge , Then does the sputtering phenomenon affect the products processed by the vacuum plasma processor? The sputtering phenomenon produced by the vacuum plasma processor is generally weak. For general products or materials, this weak sputtering phenomenon will not affect the performance of the substrate, but if the processed product has strict processing requirements, For medical-related products, the degree of sputtering of the substrate is required. Generally, the less sputtering, the weaker the better. From the electrode structure of the vacuum plasma processor, we understand the sputtering, compatible coupling radio frequency vacuum plasma surface treatment equipment, basically use aluminum alloy as the electrode, this is mainly because aluminum itself has good heat dissipation, and It has good weather resistance to plasma. Even if it is aluminum, aluminum atoms will still escape from the electrode surface under long-term plasma bombardment. Similarly, because radio frequency sputtering will bombard metal particles, the metal particles that are bombarded may adhere to the surface of the product, causing pollution, and then affecting the product. For example, the metal atoms on the surface of medical polymers will bring the body to the human body. Safety hazards; the semiconductor lead frame will affect the wire bonding quality of the product due to the injection of metal. Therefore, in order to reduce or even avoid the phenomenon of radio frequency splashing, it is necessary to adjust and optimize the cavity structure of the vacuum plasma processor, the cooling of the electrode plate, and the process parameters. We will discuss the content of this part later.

What effect does the sputtering phenomenon of the vacuum plasma processor have on the product

(Summary description)What effect does the sputtering phenomenon of the vacuum plasma processor have on the product:

When using a compatible coupling discharge vacuum plasma processor for surface treatment of material plasma, as long as the selected gas is an inert gas, a certain sputtering phenomenon will occur, which is actually independent of DC glow discharge or AC high-frequency discharge , Then does the sputtering phenomenon affect the products processed by the vacuum plasma processor?

The sputtering phenomenon produced by the vacuum plasma processor is generally weak. For general products or materials, this weak sputtering phenomenon will not affect the performance of the substrate, but if the processed product has strict processing requirements, For medical-related products, the degree of sputtering of the substrate is required. Generally, the less sputtering, the weaker the better.

From the electrode structure of the vacuum plasma processor, we understand the sputtering, compatible coupling radio frequency vacuum plasma surface treatment equipment, basically use aluminum alloy as the electrode, this is mainly because aluminum itself has good heat dissipation, and It has good weather resistance to plasma. Even if it is aluminum, aluminum atoms will still escape from the electrode surface under long-term plasma bombardment.

Similarly, because radio frequency sputtering will bombard metal particles, the metal particles that are bombarded may adhere to the surface of the product, causing pollution, and then affecting the product. For example, the metal atoms on the surface of medical polymers will bring the body to the human body. Safety hazards; the semiconductor lead frame will affect the wire bonding quality of the product due to the injection of metal.

Therefore, in order to reduce or even avoid the phenomenon of radio frequency splashing, it is necessary to adjust and optimize the cavity structure of the vacuum plasma processor, the cooling of the electrode plate, and the process parameters. We will discuss the content of this part later.

- Categories:Technical Support

- Author:Plasma cleaning machine-CRF plasma plasma equipment-plasma surface treatment machine manufacturer-chengfeng intelligent manufacturing

- Origin:

- Time of issue:2021-06-29 11:16

- Views:

What effect does the sputtering phenomenon of the vacuum plasma processor have on the product:

When using a compatible coupling discharge vacuum plasma processor for surface treatment of material plasma, as long as the selected gas is an inert gas, a certain sputtering phenomenon will occur, which is actually independent of DC glow discharge or AC high-frequency discharge , Then does the sputtering phenomenon affect the products processed by the vacuum plasma processor?

The sputtering phenomenon produced by the vacuum plasma processor is generally weak. For general products or materials, this weak sputtering phenomenon will not affect the performance of the substrate, but if the processed product has strict processing requirements, For medical-related products, the degree of sputtering of the substrate is required. Generally, the less sputtering, the weaker the better.

From the electrode structure of the vacuum plasma processor, we understand the sputtering, compatible coupling radio frequency vacuum plasma surface treatment equipment, basically use aluminum alloy as the electrode, this is mainly because aluminum itself has good heat dissipation, and It has good weather resistance to plasma. Even if it is aluminum, aluminum atoms will still escape from the electrode surface under long-term plasma bombardment.

Similarly, because radio frequency sputtering will bombard metal particles, the metal particles that are bombarded may adhere to the surface of the product, causing pollution, and then affecting the product. For example, the metal atoms on the surface of medical polymers will bring the body to the human body. Safety hazards; the semiconductor lead frame will affect the wire bonding quality of the product due to the injection of metal.

Therefore, in order to reduce or even avoid the phenomenon of radio frequency splashing, it is necessary to adjust and optimize the cavity structure of the vacuum plasma processor, the cooling of the electrode plate, and the process parameters. We will discuss the content of this part later.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen