Welcome to Shenzhen Sing Fung Intelligent Manufacturing Co., Ltd.

E-mail:shaobo@sfi-crf.com

Glass plasma surface activation treatment plasma glass processing machine application

- Categories:Company Dynamics

- Author:plasma cleaning machine-surface treatment equipment-CRF plasma machine-Sing Fung Intelligent Manufacturing

- Origin:

- Time of issue:2021-06-03

- Views:

(Summary description)Glass plasma surface activation treatment plasma glass processing machine application: Chengfeng Zhizao has accumulated a wealth of practical experience in the mobile phone glass industry, and has cooperated with many manufacturers to improve the bonding and coating performance of the glass. No matter what kind of glass is used, plasma glass processing machine plasma processing makes the bonding process easier. Plasma glass processing machine It is difficult to stick glass products, what to do? Plasma glass processing machine will help! For many people, sticking materials to glass is a complicated and difficult process. However, the use of glass plasma surface activation treatment technology can effectively solve this problem. Plasma glass cleaning includes: 1. Pre-treat glass jars and bottles before labeling. 2. Treat the glass bottle before inkjet printing. 3. Treatment of large area glass panels before coating. 4. Use UV curing adhesive to treat the glass bottle before plastic. Although the surface of the glass is smooth from the human eye, there will be some impurities on the surface from a microscopic point of view, which will hinder the adhesion. The uneven surfaces of the glass sheets and glass pieces will attract contaminants and cause many problems. Contaminants on the surface of the glass sheets will significantly reduce the bonding quality, leading to defects in the glass sheets during use. Plasma surface activation treatment of plasma glass processing machine increases the adhesion to glass due to its strong cleaning ability. The gas used to generate plasma (usually compressed air) is discharged by high-energy, after being purified by the plasma, it can be decomposed into ions, electrons, free radicals and other excited particles. This kind of excited particles can even remove organic contaminants on the glass surface at a microscopic level, and can even remove difficult-to-reach peaks and grooves. The cleaning quality of plasma is stable and reliable, ensuring that all organic pollutants can be removed from the surface of the material, and plasma treatment will ensure a stable, high-quality combination. Surface treatment provides a cost-effective, environmentally friendly and more important process before bonding, printing and coating, which is easy to repeat to ensure high-performance bonding to glass. Adding a plasma glass processing machine can not only increase adhesion, but also produce a consistent and effective effect. Plasma treatment of the glass plate before coating is an independent online surface activation method used by many large glass producers and manufacturers. This method is suitable for situations where the manufacturer wishes to increase the bonding strength of the glass plate before painting. Plasma surface treatment can be uniformly processed on glass panels of different sizes, and the processing speed does not change much, providing consistent, uniform and activated processing for the glass. Plasma glass processing machine plasma processing technology can significantly improve the production process, ensuring the increase in speed and efficiency.

Glass plasma surface activation treatment plasma glass processing machine application

(Summary description)Glass plasma surface activation treatment plasma glass processing machine application:

Chengfeng Zhizao has accumulated a wealth of practical experience in the mobile phone glass industry, and has cooperated with many manufacturers to improve the bonding and coating performance of the glass. No matter what kind of glass is used, plasma glass processing machine plasma processing makes the bonding process easier.

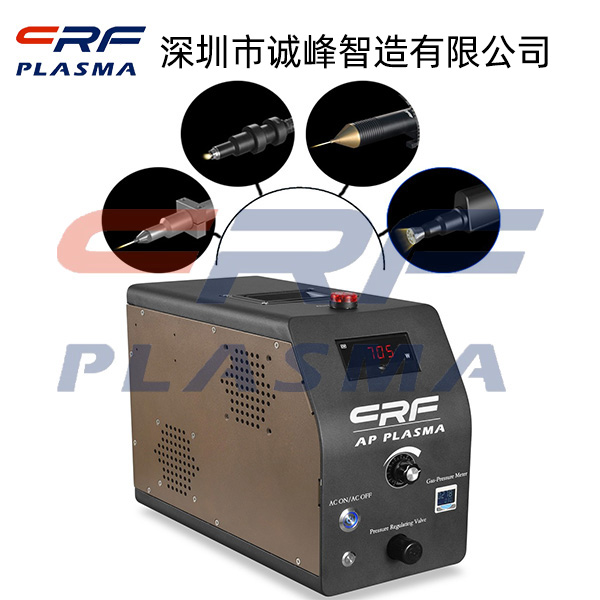

Plasma glass processing machine

It is difficult to stick glass products, what to do? Plasma glass processing machine will help! For many people, sticking materials to glass is a complicated and difficult process. However, the use of glass plasma surface activation treatment technology can effectively solve this problem.

Plasma glass cleaning includes:

1. Pre-treat glass jars and bottles before labeling.

2. Treat the glass bottle before inkjet printing.

3. Treatment of large area glass panels before coating.

4. Use UV curing adhesive to treat the glass bottle before plastic.

Although the surface of the glass is smooth from the human eye, there will be some impurities on the surface from a microscopic point of view, which will hinder the adhesion. The uneven surfaces of the glass sheets and glass pieces will attract contaminants and cause many problems. Contaminants on the surface of the glass sheets will significantly reduce the bonding quality, leading to defects in the glass sheets during use.

Plasma surface activation treatment of plasma glass processing machine increases the adhesion to glass due to its strong cleaning ability. The gas used to generate plasma (usually compressed air) is discharged by high-energy, after being purified by the plasma, it can be decomposed into ions, electrons, free radicals and other excited particles. This kind of excited particles can even remove organic contaminants on the glass surface at a microscopic level, and can even remove difficult-to-reach peaks and grooves.

The cleaning quality of plasma is stable and reliable, ensuring that all organic pollutants can be removed from the surface of the material, and plasma treatment will ensure a stable, high-quality combination. Surface treatment provides a cost-effective, environmentally friendly and more important process before bonding, printing and coating, which is easy to repeat to ensure high-performance bonding to glass. Adding a plasma glass processing machine can not only increase adhesion, but also produce a consistent and effective effect.

Plasma treatment of the glass plate before coating is an independent online surface activation method used by many large glass producers and manufacturers. This method is suitable for situations where the manufacturer wishes to increase the bonding strength of the glass plate before painting. Plasma surface treatment can be uniformly processed on glass panels of different sizes, and the processing speed does not change much, providing consistent, uniform and activated processing for the glass. Plasma glass processing machine plasma processing technology can significantly improve the production process, ensuring the increase in speed and efficiency.

- Categories:Company Dynamics

- Author:plasma cleaning machine-surface treatment equipment-CRF plasma machine-Sing Fung Intelligent Manufacturing

- Origin:

- Time of issue:2021-06-03 16:49

- Views:

Glass plasma surface activation treatment plasma glass processing machine application:

Chengfeng Zhizao has accumulated a wealth of practical experience in the mobile phone glass industry, and has cooperated with many manufacturers to improve the bonding and coating performance of the glass. No matter what kind of glass is used, plasma glass processing machine plasma processing makes the bonding process easier.

Plasma glass processing machine

It is difficult to stick glass products, what to do? Plasma glass processing machine will help! For many people, sticking materials to glass is a complicated and difficult process. However, the use of glass plasma surface activation treatment technology can effectively solve this problem.

Plasma glass cleaning includes:

1. Pre-treat glass jars and bottles before labeling.

2. Treat the glass bottle before inkjet printing.

3. Treatment of large area glass panels before coating.

4. Use UV curing adhesive to treat the glass bottle before plastic.

Although the surface of the glass is smooth from the human eye, there will be some impurities on the surface from a microscopic point of view, which will hinder the adhesion. The uneven surfaces of the glass sheets and glass pieces will attract contaminants and cause many problems. Contaminants on the surface of the glass sheets will significantly reduce the bonding quality, leading to defects in the glass sheets during use.

Plasma surface activation treatment of plasma glass processing machine increases the adhesion to glass due to its strong cleaning ability. The gas used to generate plasma (usually compressed air) is discharged by high-energy, after being purified by the plasma, it can be decomposed into ions, electrons, free radicals and other excited particles. This kind of excited particles can even remove organic contaminants on the glass surface at a microscopic level, and can even remove difficult-to-reach peaks and grooves.

The cleaning quality of plasma is stable and reliable, ensuring that all organic pollutants can be removed from the surface of the material, and plasma treatment will ensure a stable, high-quality combination. Surface treatment provides a cost-effective, environmentally friendly and more important process before bonding, printing and coating, which is easy to repeat to ensure high-performance bonding to glass. Adding a plasma glass processing machine can not only increase adhesion, but also produce a consistent and effective effect.

Plasma treatment of the glass plate before coating is an independent online surface activation method used by many large glass producers and manufacturers. This method is suitable for situations where the manufacturer wishes to increase the bonding strength of the glass plate before painting. Plasma surface treatment can be uniformly processed on glass panels of different sizes, and the processing speed does not change much, providing consistent, uniform and activated processing for the glass. Plasma glass processing machine plasma processing technology can significantly improve the production process, ensuring the increase in speed and efficiency.

Scan the QR code to read on your phone

TEL:0755-3367 3020 / 0755-3367 3019

E-mail:sales-sfi@sfi-crf.com

ADD:Mabao Industrial Zone, Huangpu, Baoan District, Shenzhen